Explosion venting top mechanism and application method

A technology of explosion venting and explosion venting, which is applied in the field of container explosion venting roof mechanism, can solve the problems of not considering the accident of the box body, achieve the effects of good monitoring ability and information feedback ability, good versatility, and reduce the degree of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific implementation methods, taking hydrogen as an example.

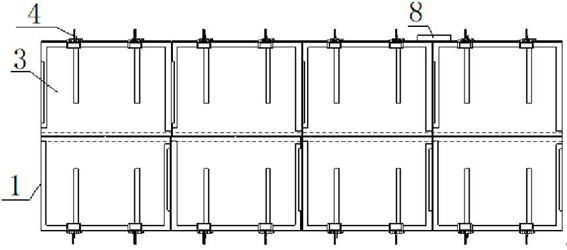

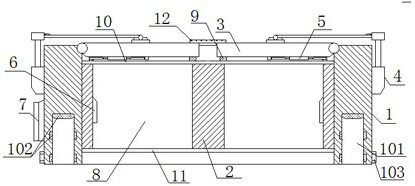

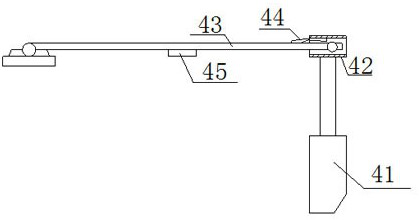

[0028] Such as figure 1Shown in -5, a kind of explosion venting top mechanism comprises positioning sleeve 1, positioning pedestal 2, explosion venting top cover 3, explosion venting driving mechanism 4, reset driving mechanism 5, combustible gas concentration sensor 6 and drive circuit 7, positioning Sleeve 1 is a columnar frame-shaped metal structure with a rectangular cross section. Positioning base frame 2 is a frame structure coaxially distributed with positioning sleeve 1 and embedded in positioning sleeve 1. Positioning base frame 2 is a number of explosion vents 8 evenly distributed on the top. , the explosion vents 8 are symmetrically distributed on both sides of the center line of the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com