Medical reagent small bottle filling machine

A canning machine, a small-scale technology, applied in the field of canning, can solve the problems of time-consuming and laborious work efficiency, low degree of automation, and a large amount of manpower, and achieve the effects of improved production efficiency, high degree of automation, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

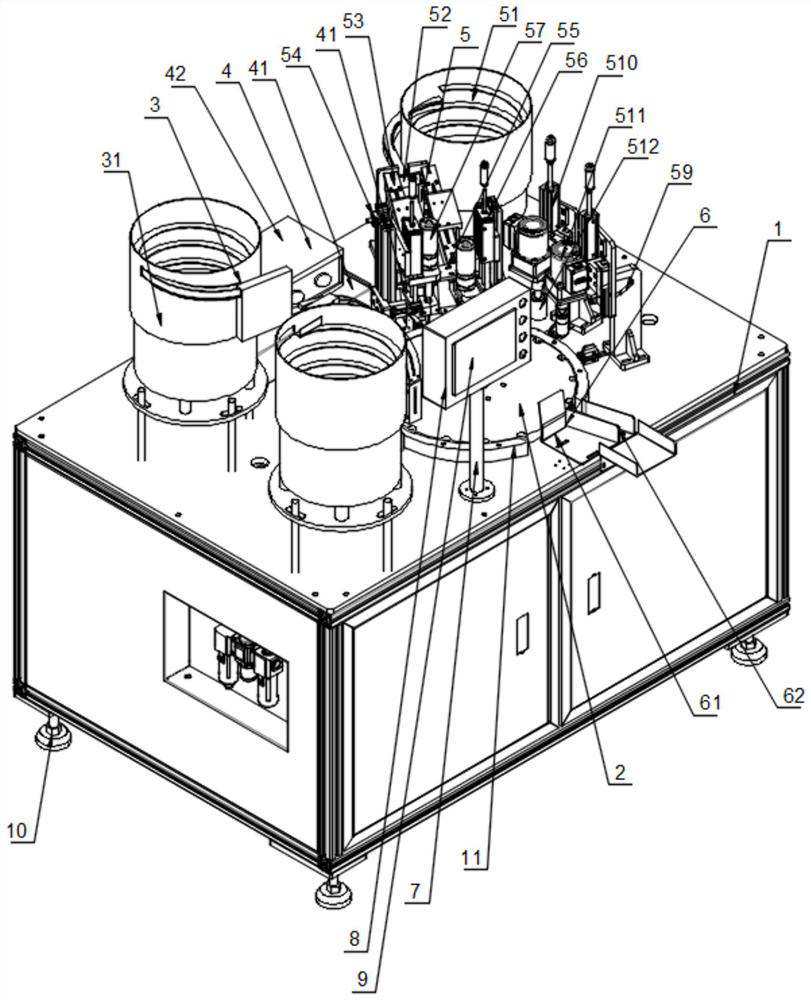

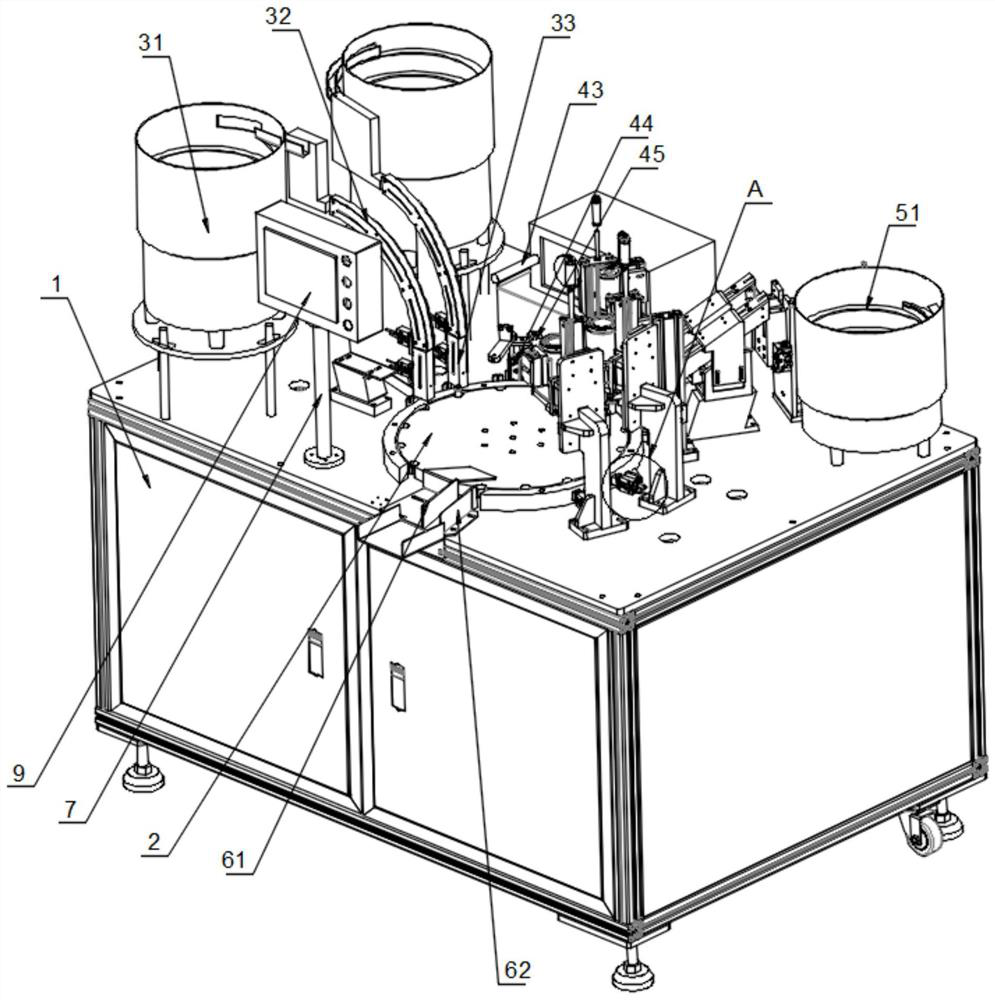

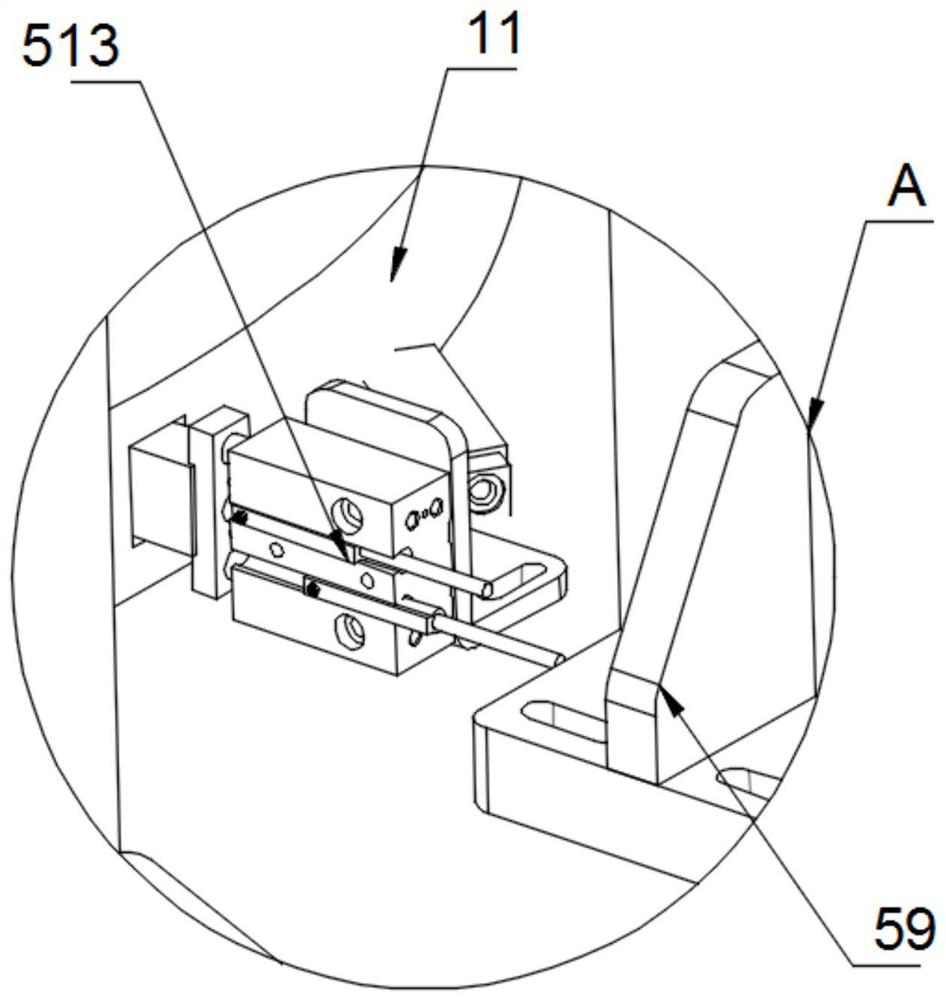

[0027] Refer to the attached Figure 1-6 , a small canning machine for medical reagents in this embodiment includes a frame 1, a workbench 2 is provided on the top of the frame 1, and a support ring 11 is provided on the outside of the workbench 2, and the support ring 11 is fixedly installed On the top of the frame 1, a motor 12 is fixedly installed inside the frame 1, the output shaft of the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap