A lead brass rod suitable for high-speed automatic processing and its preparation method

A lead brass, high-speed technology, applied in the field of lead brass rods and its preparation, can solve the problems of lead brass low strength, small order quantity, large area occupied by continuous pulling and unwinding equipment, etc., and achieve excellent cutting performance , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

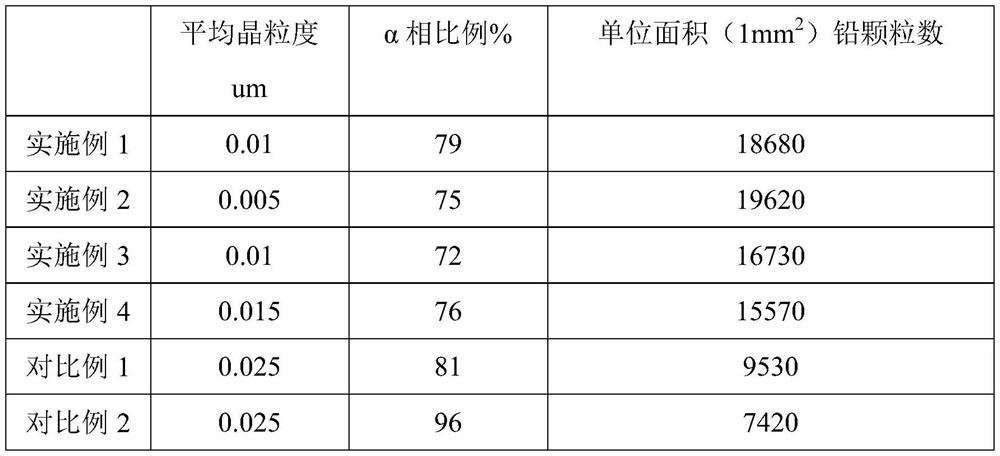

Examples

preparation example Construction

[0026] In summary, the preparation method of the lead brass rod suitable for high-speed automatic processing in the present invention comprises the following steps:

[0027] S1: Smelting and casting: After mixing and melting each component in proportion, an ingot is produced by horizontal continuous casting, and the specification of the ingot is Φ140-250mm;

[0028] S2: Extrusion: peeling and extruding the ingot after heating to obtain an extruded billet, the specification of the extruded billet is Φ4.5-23.0 mm;

[0029] S3: pickling: soak the extruded billet in a sulfuric acid solution for 2-5 minutes, rinse it with high-pressure water, and obtain a rod billet;

[0030] S4: combined drawing: performing combined drawing on the rod blank to obtain the lead brass rod suitable for high-speed automatic processing.

[0031] In a specific embodiment, in step 1, magnesium, calcium and phosphorus are added in the form of an intermediate alloy with copper.

[0032] In a specific embo...

Embodiment 1

[0038] This embodiment provides a lead brass rod suitable for high-speed automatic processing, and its preparation method includes the following steps:

[0039] S1: Smelting and casting: 1# red copper, 2# red copper, copper-iron alloy, brass scraps, lead brass scraps, tin-phosphorus bronze scraps, zinc ingots, lead ingots, copper-magnesium alloys, copper-phosphorus Alloys are added to the induction furnace in batches for melting. The melting temperature is 1060°C. After the metal is completely melted, it is stirred evenly. After standing for 20 minutes, the ingot is produced by horizontal continuous casting. The ingot size is Φ200mm. Sawing on the band sawing machine, the sawing length is 1200mm;

[0040] S2: Extrusion: The ingot is heated in a medium-frequency induction heating furnace, and the heating adopts four stages of gradient heating. The temperature of the first stage is heated to 300°C, and the heating time is 25 minutes; the temperature of the second stage is heated...

Embodiment 2

[0046] This embodiment provides a lead brass rod suitable for high-speed automatic processing, and its preparation method includes the following steps:

[0047] S1: Melting and casting: 1# red copper, 2# red copper, copper-iron alloy, brass scrap, lead brass shavings, tin phosphor bronze scrap, zinc ingot, lead ingot, copper-calcium alloy in batches according to the ratio in Table 1 Put it into an induction furnace for melting, the melting temperature is 1040°C, stir evenly after all the metal is melted, and after standing for 20 minutes, produce ingots by horizontal continuous casting, the ingot size is Φ145mm, and the ingots are cast on a semi-automatic horizontal metal band saw Sawing, sawing length 500mm;

[0048] S2: Extrusion: The ingot is heated in a medium-frequency induction heating furnace, and the heating adopts four stages of gradient heating. The temperature of the first stage is heated to 300°C, and the heating time is 15 minutes; the temperature of the second stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com