Detection and control method of range hood and range hood

A detection control and range hood technology, which is applied to the removal of oil fume, heating methods, computer parts, etc., can solve the problems of inaccurate detection results, failure, dirt, etc., and achieve the effect of convenient cleaning of camera components and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Such as Figure 5-Figure 8 As shown, this embodiment describes the structure of the image acquisition device of the range hood.

[0092] The image acquisition device 100 of the range hood structure in the embodiment of the present invention is installed on the panel bracket of the range hood, embedded in the panel or installed on the inner bracket of the panel, wherein the image acquisition device 100 includes a sheet metal bracket 3 of the hood panel And hood control panel glass 2, image recognition camera 1 and camera protective glass 4 installed on the sheet metal bracket for protecting image recognition camera, also includes sensor protection air duct structure 5. The purpose of adopting this structure is to ensure that the sampling angle of view of the image acquisition device 100 is sufficient to cover the entire cooktop space. The advantage of installing through the installation guide groove 6 is that it is convenient for production and disassembly, and the appea...

Embodiment 2

[0101] Such as Figure 4 As shown, the range hood includes a hood control unit 200, an image acquisition device 100, a fan mechanism 300, a lighting control drive circuit 400, and an alarm reminder circuit 500, wherein the functions of each module are as follows:

[0102]Range hood control unit 200: range hood control circuit, responsible for the function operation of the range hood, signal acquisition and load control lights. First, the control unit communicates with the image acquisition device to realize self-inspection of the camera component, detection of oil volume in the oil collection box and acquisition The real-time oil fume concentration data calculates the corresponding function operation command and the air volume demand under the condition of oil fume concentration, and controls the fan to perform the oil fume suction function at a certain speed through the fan control circuit. When the image acquisition device detects that the oil collection box is full, the hoo...

Embodiment 3

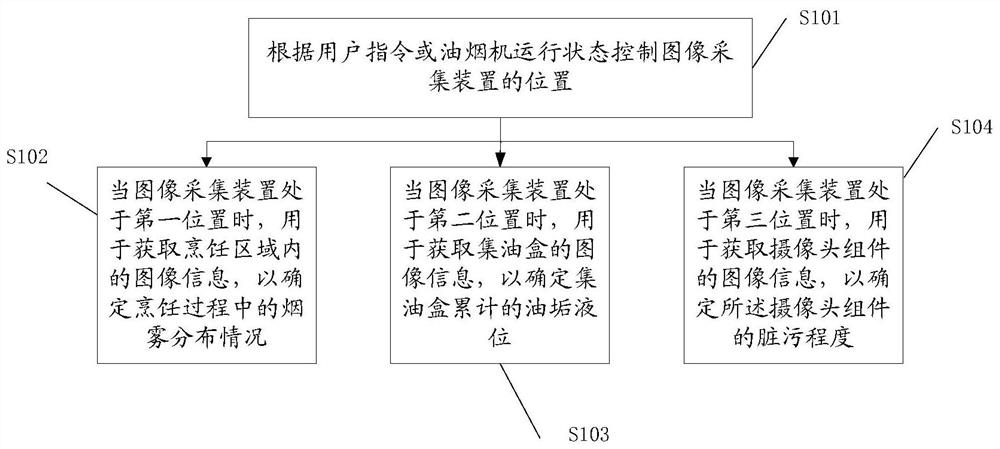

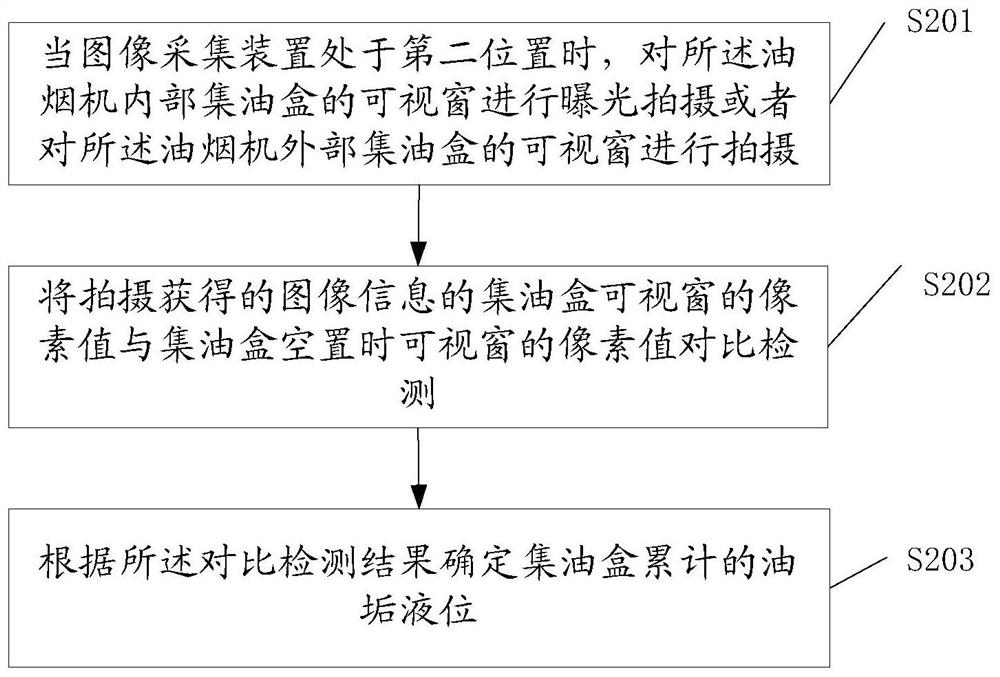

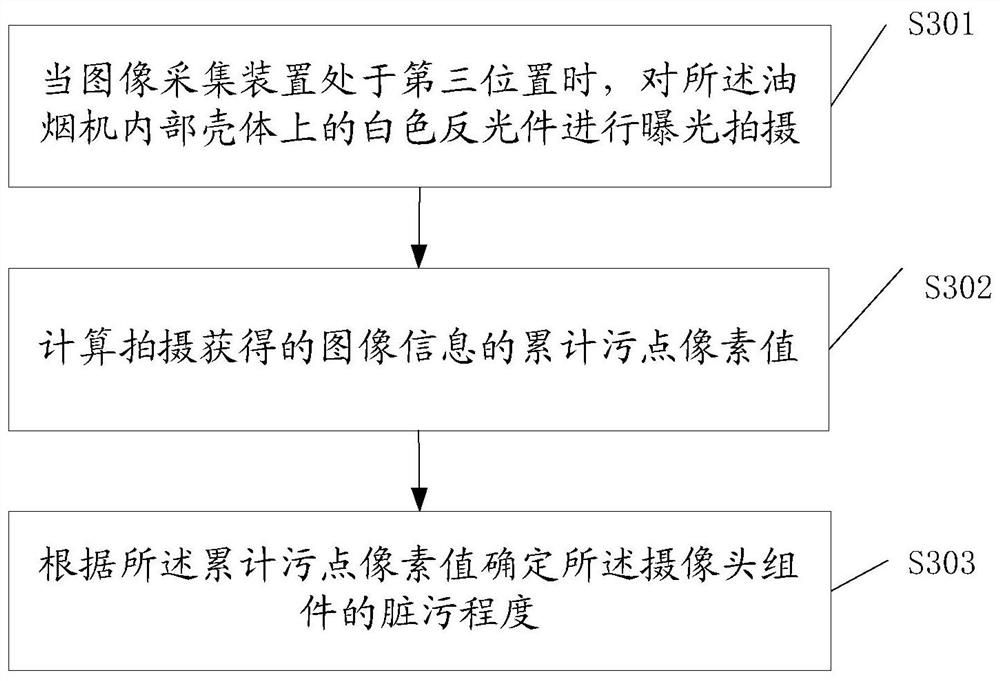

[0114] This embodiment illustrates the working process of determining the range hood:

[0115] After the range hood is powered on, the image acquisition device performs a position self-inspection program to determine whether the camera 1 is at the zero angle position, which is the reset position. Figure 9 As shown, the reset position of the camera 1 is that the range hood is closed, the camera 1 is closed inside the range hood, and the camera 1 faces the positive direction of the x-axis. If the camera 1 is set at 0° at this time, the image acquisition device enters Camera cleaning detection program, otherwise the camera assembly will run position self-adjustment control, this control makes the camera 1 rotate from the positive direction of the x-axis to the positive direction of the y-axis, and when it rotates to the positive direction of the y-axis, the accumulated grease level of the oil collection box will be checked. Detection, set the camera 1 at the 90° position at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com