Coating for fruit

A technology for fruits and fruit products, which is applied in the direction of coating, preservation of fruits and vegetables, and protection of fruits/vegetables with coating protection layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

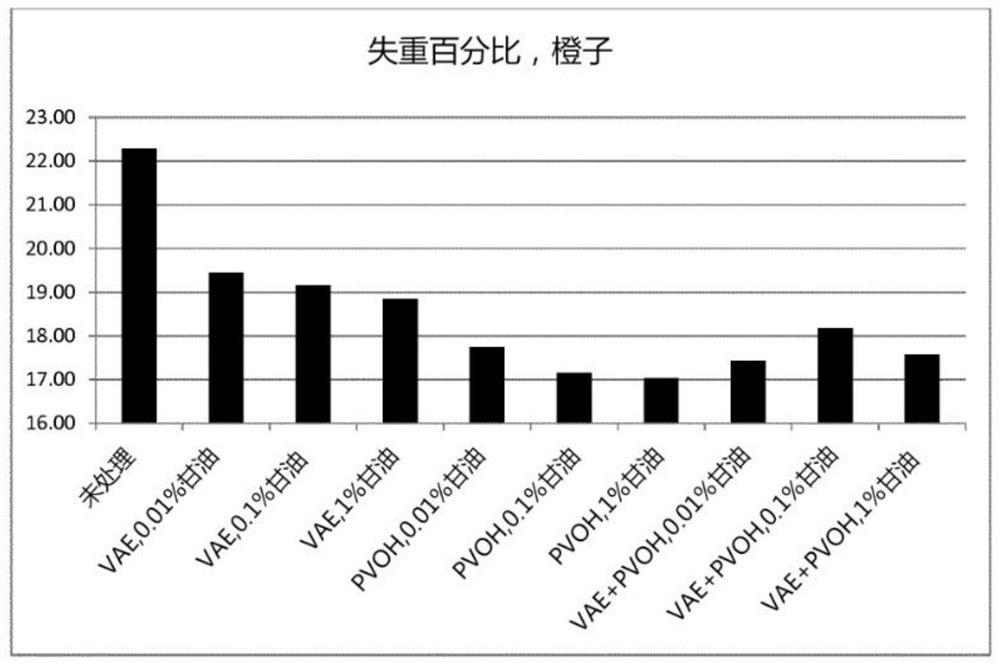

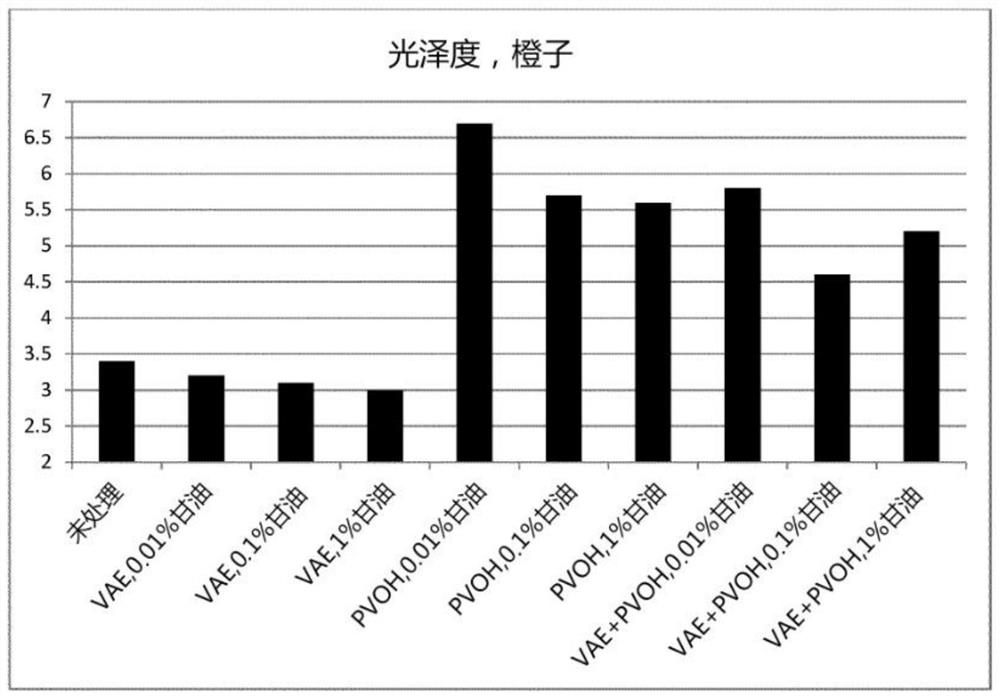

[0079] Example 1: Oranges

[0080] To test the effect of coating postharvest oranges with various compositions of the invention, the fruit was coated with the following compositions:

[0081] 1) 5% w / v solution of a copolymer of ethylene and vinyl acetate (VAE) to which glycerol was added in concentrations of 0.01%, 0.1% and 1% by weight, based on the weight of the polymer. These compositions are indicated in Tables 1-4 below as "VAE, 0.01% Glycerin", "VAE, 0.1% Glycerin", and "VAE, 1% Glycerin".

[0082] 2) 7.5% w / v solution of a homopolymer of polyvinyl alcohol (PVOH) to which glycerol was added in concentrations of 0.01%, 0.1% and 1% by weight, based on the weight of the polymer. These compositions are indicated in Tables 1-4 below as "PVOH, 0.01% Glycerin", "PVOH, 0.1% Glycerin", and "PVOH, 1% Glycerin".

[0083] 3) A solution of 3.75% by weight / volume of polyvinyl alcohol homopolymer (PVOH) and 2.5% by weight / volume of a copolymer of ethylene and vinyl acetate (VAE), wh...

Embodiment 2

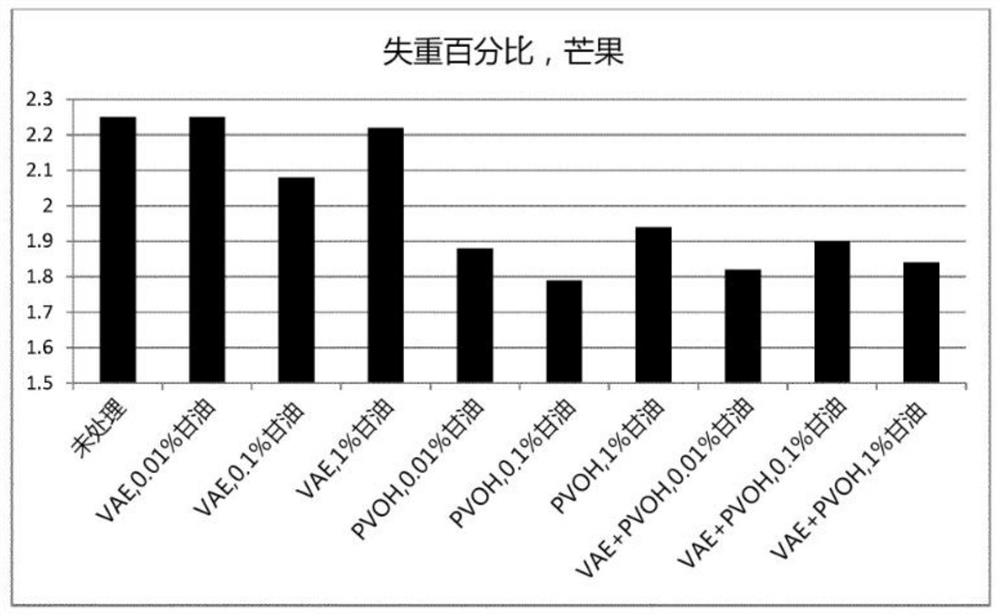

[0093] Embodiment 2: mango

[0094] The test described in Example 1 was also carried out on mangoes by dipping a known weight of mangoes into one of the above compositions described in Example 1 so as to obtain a layer thickness of 5-7.5 μm. Control mangoes were not coated. The same conditions as in Example 1 were used unless otherwise stated.

[0095] After 9 days of incubation, the weight of the mangoes was determined again and the average weight loss of each mango 9 days after application of the coating was calculated from a group of 6 mangoes that had undergone the same treatment. Gloss was evaluated as described in Example 1. The results are shown in Table 3.

[0096] Table 2: Weight loss and gloss after 9 days with various coatings: Mango

[0097] combination Weight loss after 9 days (%) Gloss (Day 9) unprocessed 2.25 1.94 VAE, 0.01% Glycerin 2.25 1.17 VAE, 0.1% Glycerin 2.08 1.17 VAE, 1% glycerin 2.22 1.33 PVOH, 0.01% G...

Embodiment 3

[0101] Example 3: Papaya

[0102] The test described in Example 1 was also carried out on papaya by dipping a known weight of papaya into one of the above compositions described in Example 1 so as to obtain a layer thickness of 5-7.5 μm. Control papayas were not coated. The same conditions as in Example 1 were used unless otherwise stated.

[0103] After 13 days of incubation, the weight of the papayas was determined again, and the average weight loss of each papaya 13 days after application of the coating was calculated from a group of 6 papayas that had undergone the same treatment. Gloss was also assessed as described in Example 1, in this case the first day after application of the coating. The results are shown in Table 3.

[0104] Table 3: Weight loss and gloss after 13 days with various coatings: Papaya

[0105] combination Weight loss after 13 days (%) Gloss (Day 1) unprocessed 29.16 1.00 VAE, 0.01% Glycerin 21.91 1.50 VAE, 0.1% Glyce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com