Apparatus and method for manufacturing iron block using iron pieces

A technology of iron filings and iron lumps, which is applied in the direction of improving process efficiency, etc., can solve the problems of reducing the ratio of iron filings reuse, and achieve the effects of avoiding strength reduction, minimizing weight loss, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

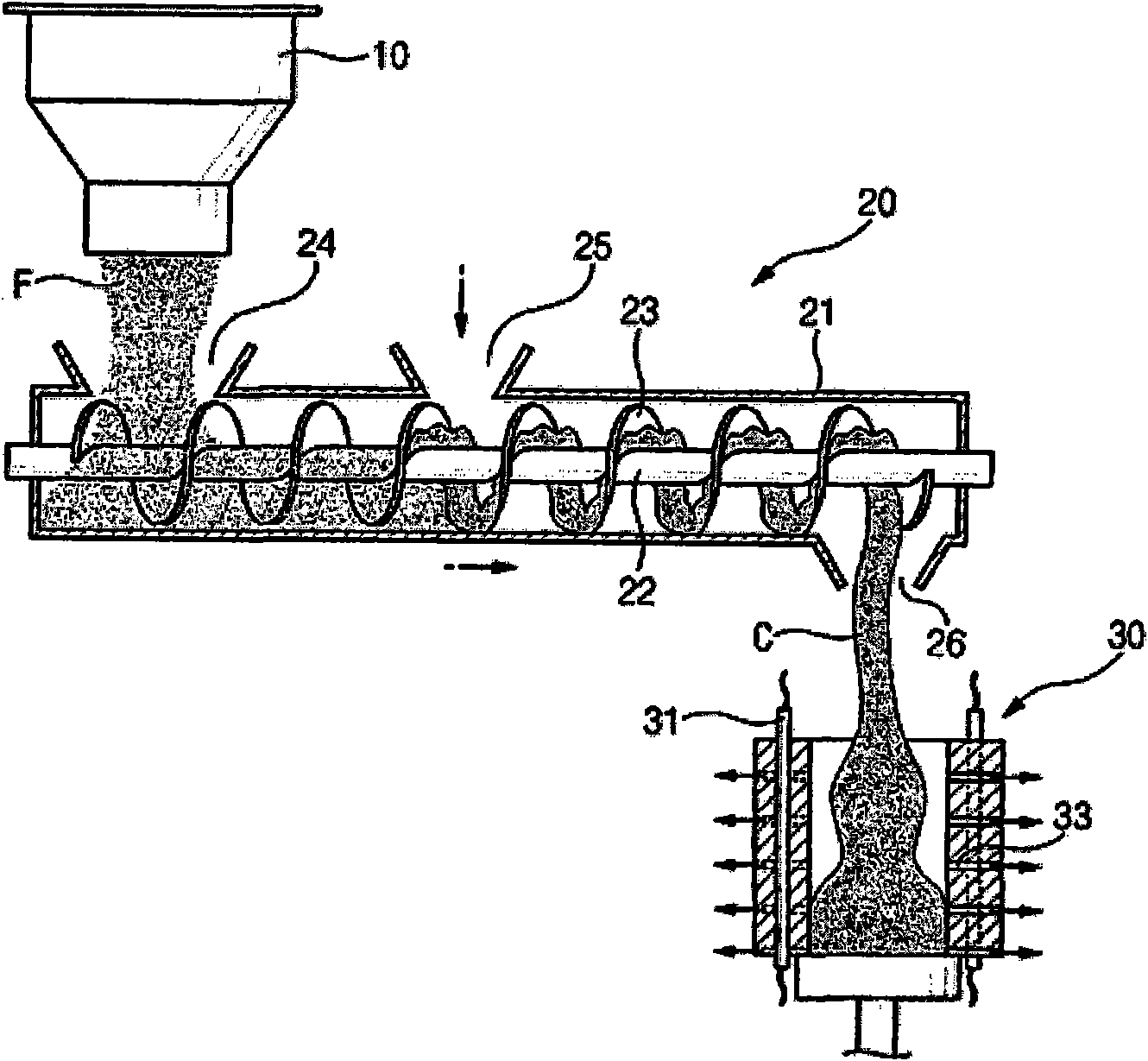

[0034] A better understanding of the technical construction and effects of the device and method for manufacturing iron blocks using iron filings according to the present invention can be obtained through the following detailed description in conjunction with the accompanying drawings, which illustrate the preferred embodiment.

[0035] Apparatus for making iron blocks

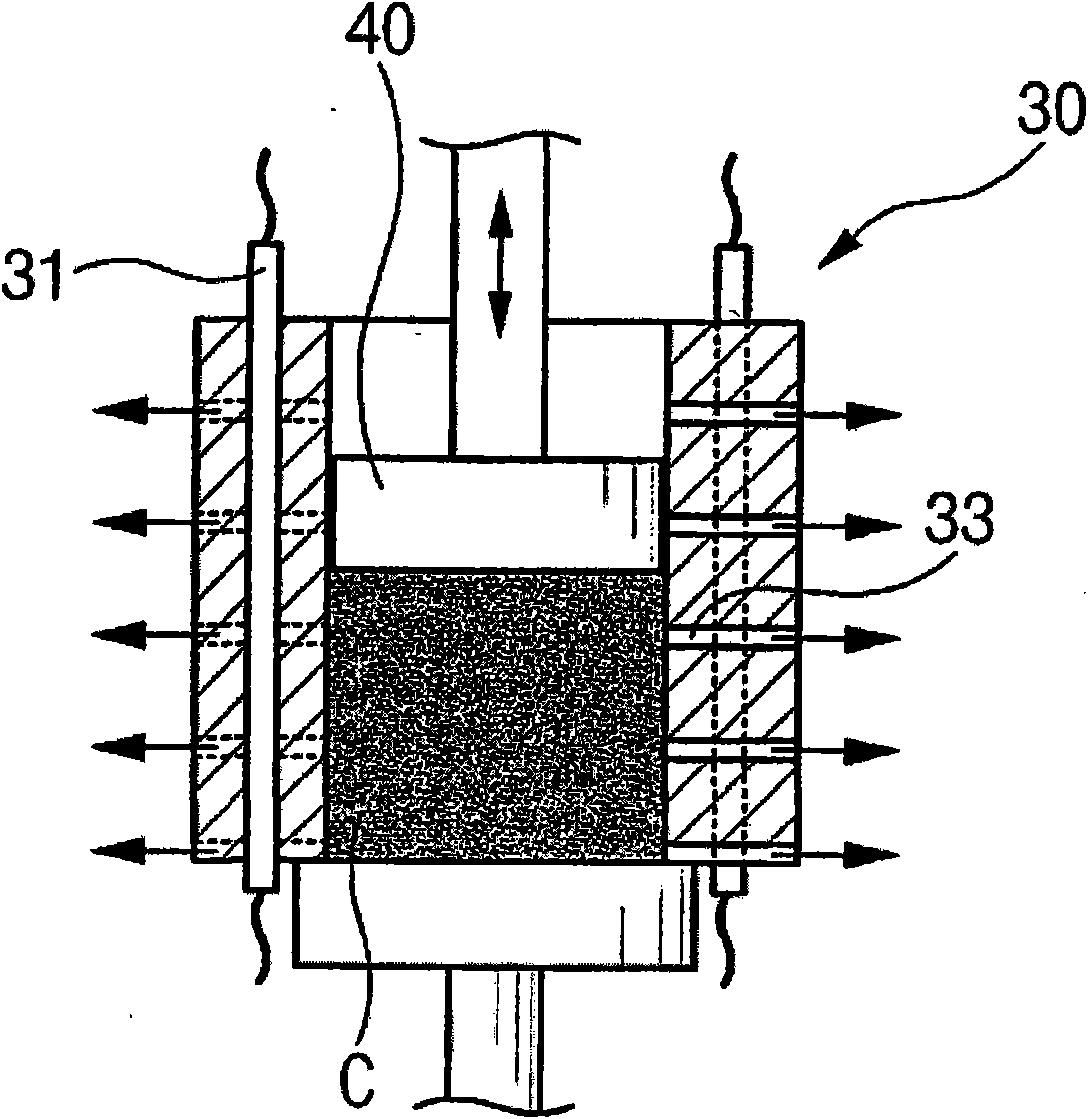

[0036] In the attached picture, figure 1 To show a schematic diagram of an apparatus for manufacturing iron blocks according to the present invention, figure 2 is a sectional view showing the shaper integrated in the device according to the present invention.

[0037] As shown in the figure, the device for manufacturing iron ingots according to the present invention includes: a stocker 10, an agitator 20 and a shaper 30, the agitator 20 is located directly below the stocker 10 and has a central shaft 22 On and around the impeller 23, the shaper 30 is located just below the end of the agitator 20 and into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com