Automatic labeling device for toy producing and processing

A labeling and toy technology, applied in labeling, labeling machines, packaging, etc., can solve the problems of insufficient labeling efficiency and no production line, and achieve the effects of fast labeling efficiency, improved production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

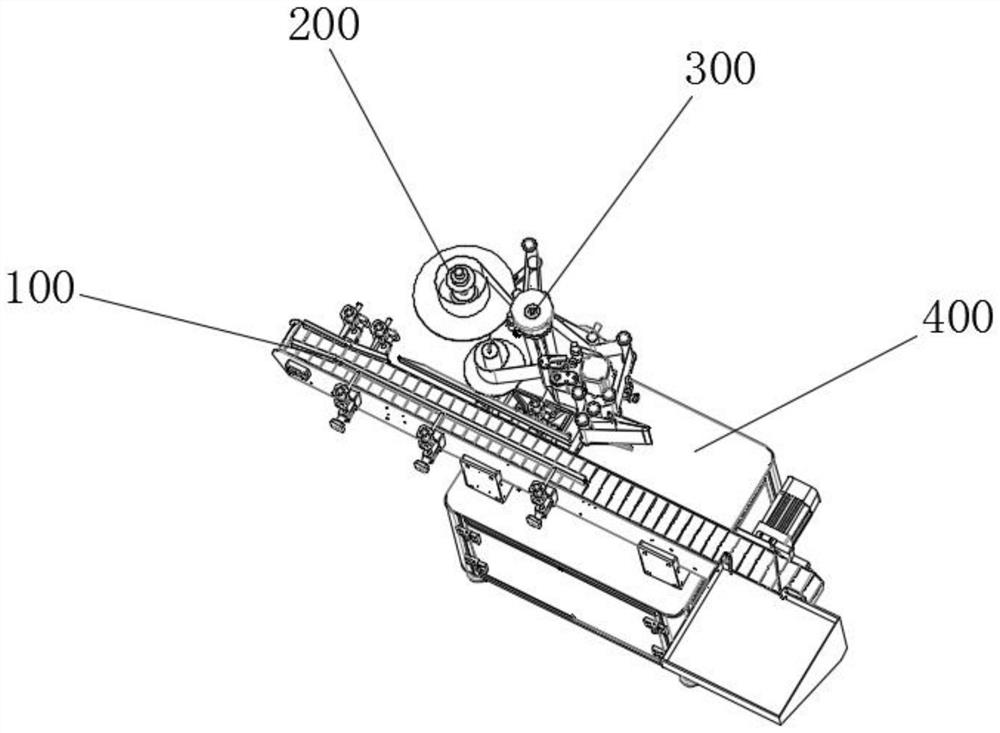

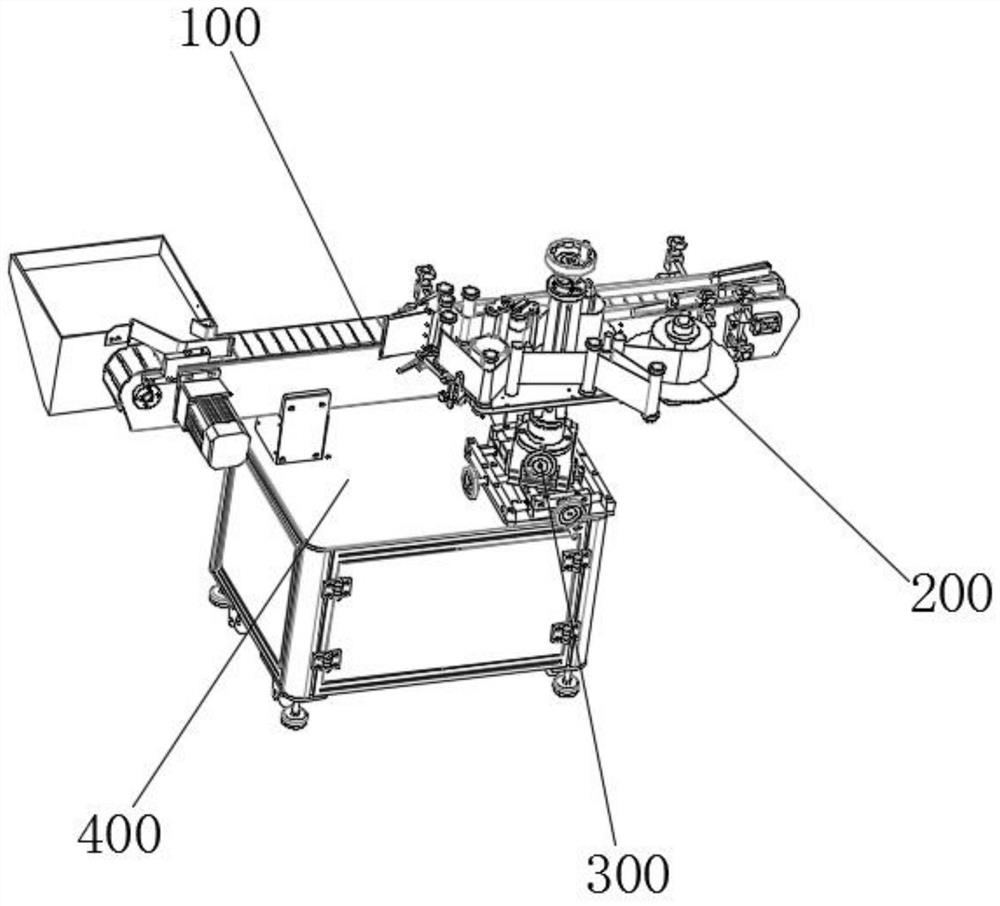

[0036] see Figure 1-10 As shown, this embodiment is an automatic labeling device for toy production and processing, including a conveying mechanism 100, a labeling mechanism 200, an adjusting mechanism 300, and a mounting base 400. The conveying mechanism 100 is installed on the top side of the mounting base 400. An adjustment mechanism 300 is installed at the end of the top of the installation base 400 away from the conveying mechanism 100, and a labeling mechanism 200 is installed at the top of the adjustment mechanism 300;

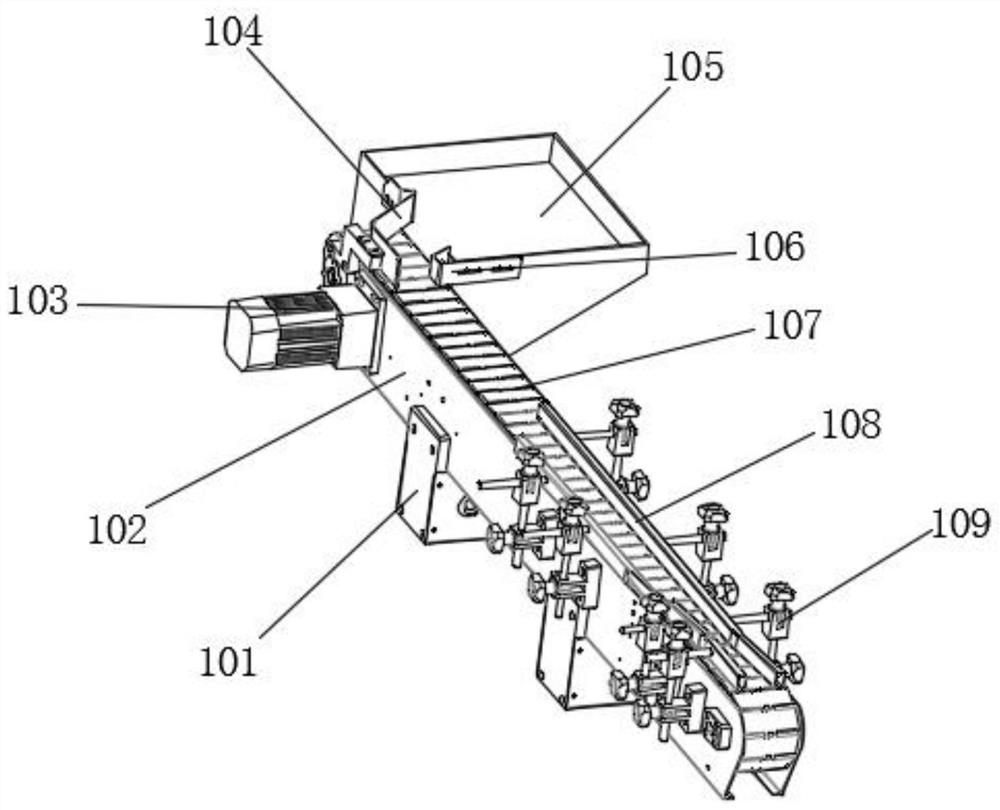

[0037] Wherein, the conveying mechanism 100 includes a support base 101, a conveyor mounting frame 102, a conveying motor 103, a first guide plate 104, a collecting tray 105, a second guide plate 106, a conveyor 107, a limit plate 108, and an adjustment unit 109 , the conveyor mounting frame 102 is erected and installed on two support bases 101, a conveyor 107 is installed on the conveyor mounting frame 102, and a collecting tray 105 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com