Cigarette 3d printer

A technology of 3D printers and cigarettes, which is applied in the fields of tobacco, paper cigarettes, and smoke oil filter elements, etc., can solve the problems of cumbersome production process of cigarettes, and achieve the effect of reducing the difficulty of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

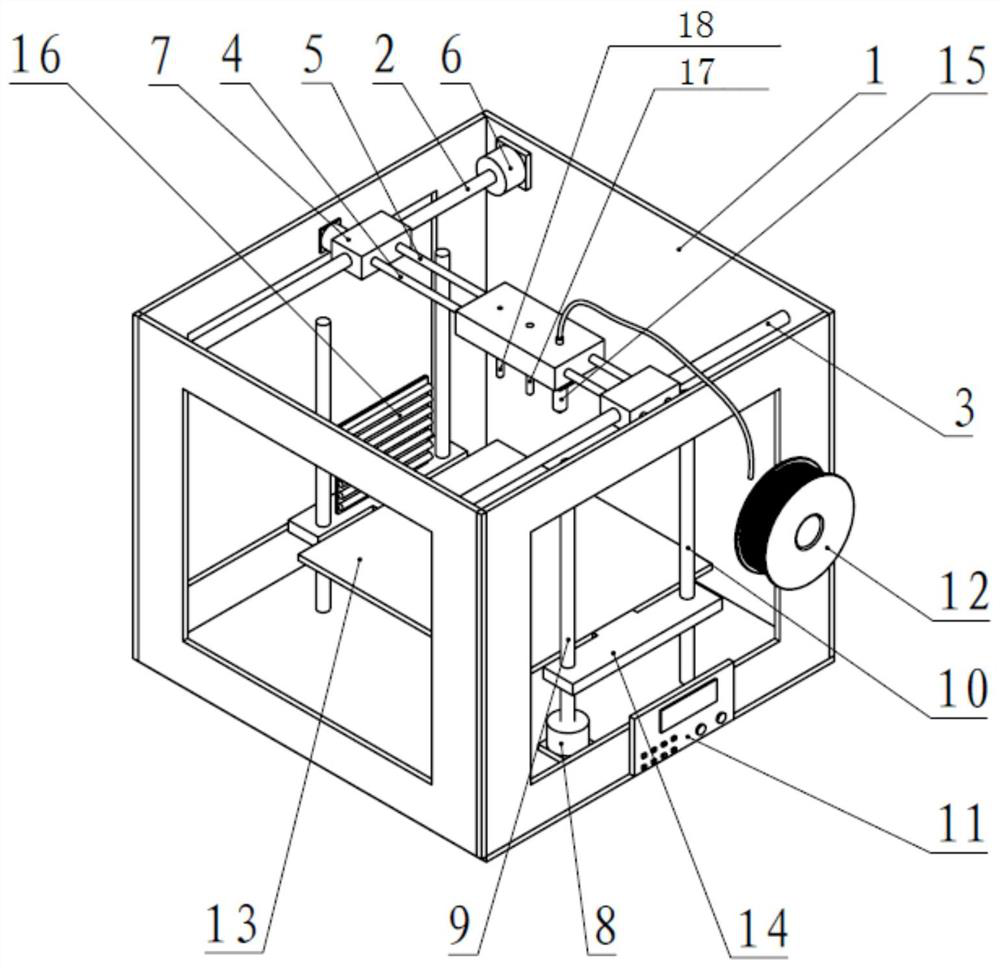

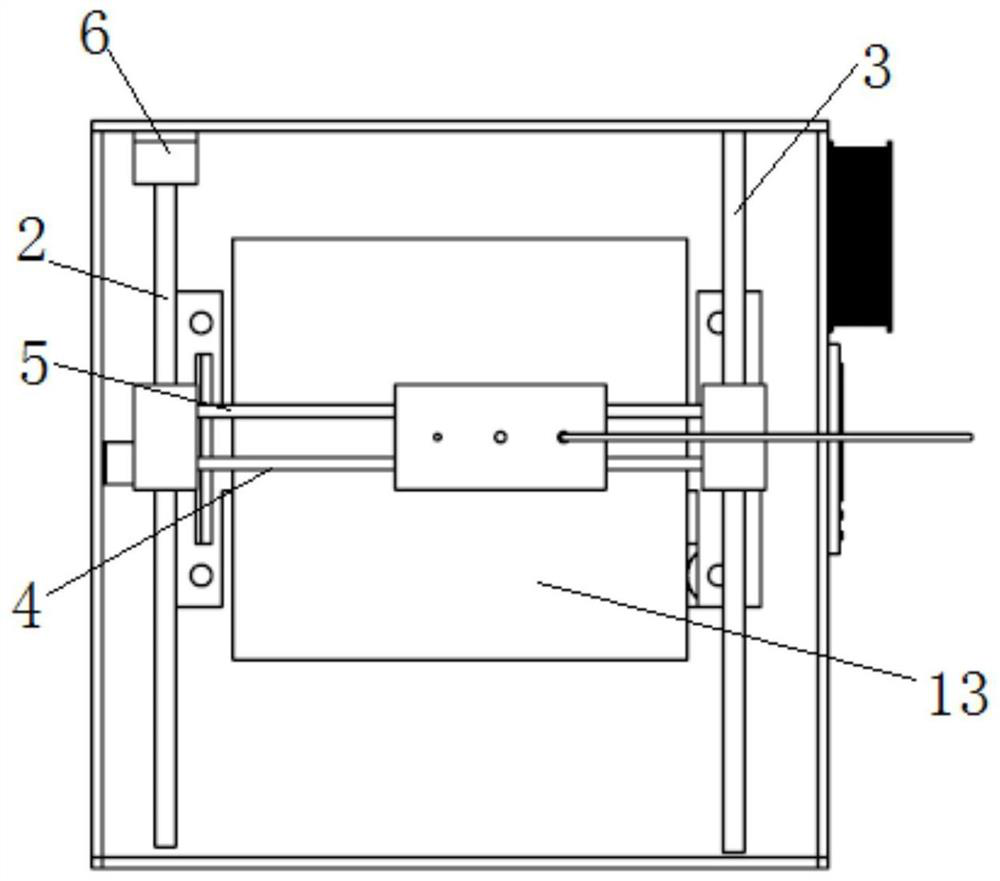

[0056] In this embodiment, the drive unit includes: a first screw rod 2, which is arranged above the receiving plate 13, the first screw rod 2 extends horizontally and longitudinally, and its driving part is connected to the output shaft of the first motor 6 which can be rotated forward and backward; The second screw mandrel 4 is arranged on the top of the receiving plate 13, and the second screw mandrel 4 extends horizontally and laterally, and its driving part is connected with the second motor 7 which is arranged on the sliding part of the first screw mandrel 2 and can be rotated forward and backward. ; The nozzle module is located on the sliding part of the second screw mandrel 4 .

[0057] The present invention realizes the movement of the spray head module in the horizontal transverse direction and the horizontal longitudinal direction through the above arrangement.

[0058] Screws are one of the most common mechanical parts. The main function of the screw is to convert...

Embodiment 2

[0062] The difference between this embodiment and the above-mentioned first embodiment is that the drive unit also includes: a second slide rod 5, which is parallel to the second screw rod 4 in the horizontal direction and arranged at a certain distance, and its two ends are respectively connected to the first screw rod. The sliding part of 2 is connected with the first sliding part; the sliding part of the second screw rod 4 is slidingly connected with the second sliding rod 5; the nozzle module is arranged on the sliding part of the second screw rod 4 and connected with the second sliding rod 5 The gap between the second threaded mandrel 4 is set correspondingly in the vertical direction.

[0063] The present invention improves the stability of the nozzle module arranged on the sliding part of the second screw rod 4 by slidingly connecting the sliding part of the second screw rod 4 with the second sliding rod 5 .

[0064] In some embodiments, the second screw rod 4 includes ...

Embodiment 3

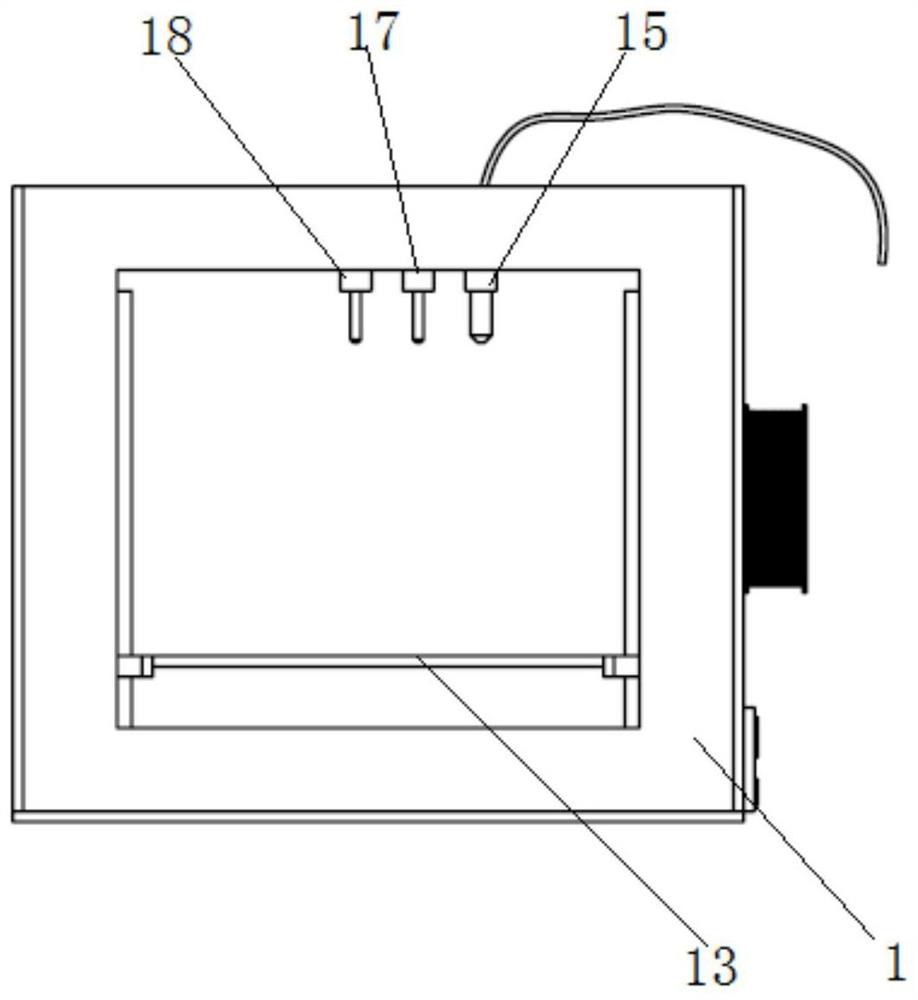

[0066] The difference between this embodiment and the above-mentioned first and second embodiments is that the drive unit also includes: a third screw rod 9, which is arranged below the first screw rod 2, and the third screw rod 9 extends vertically, and its driving part can be aligned with The output shaft of the reversed third motor 8 is connected; the support member 14 is connected with the sliding part of the third screw rod 9 ; the receiving plate 13 is connected with the support member 14 .

[0067] The present invention realizes the vertical movement of the receiving plate 13 through the above arrangement.

[0068] Preferably, the drive unit also includes: a third slide bar 10, which is arranged in parallel with the third screw mandrel 9 in the vertical direction and at a certain distance; The other side is slidably connected with the third slide bar 10 . Specifically, the driving unit further includes a sliding piece, which is slidably connected to the third sliding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com