Vertical bending machine

A bending machine and vertical technology, applied in the field of vertical bending machines and bending machines, can solve the problems of limited workshop operating table and space height, low work efficiency, etc., and achieve simple structure, high work efficiency, and highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

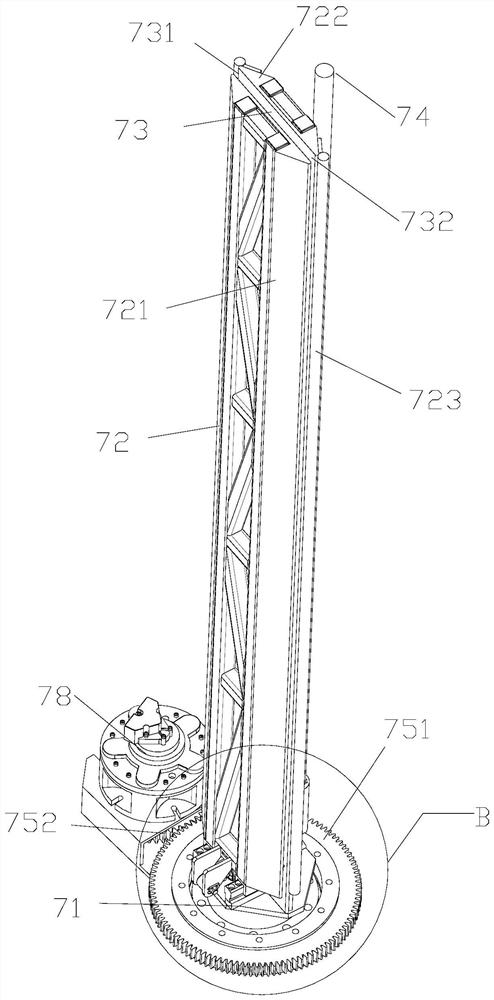

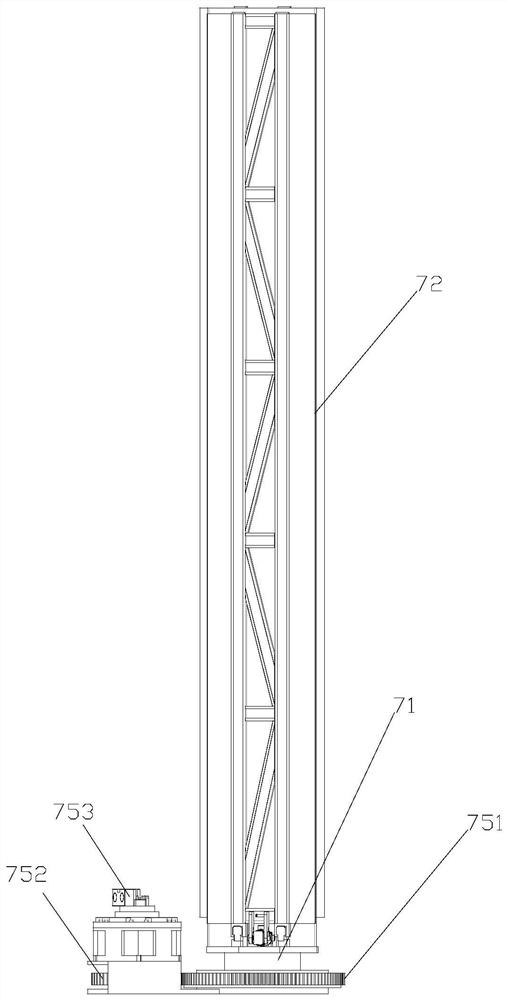

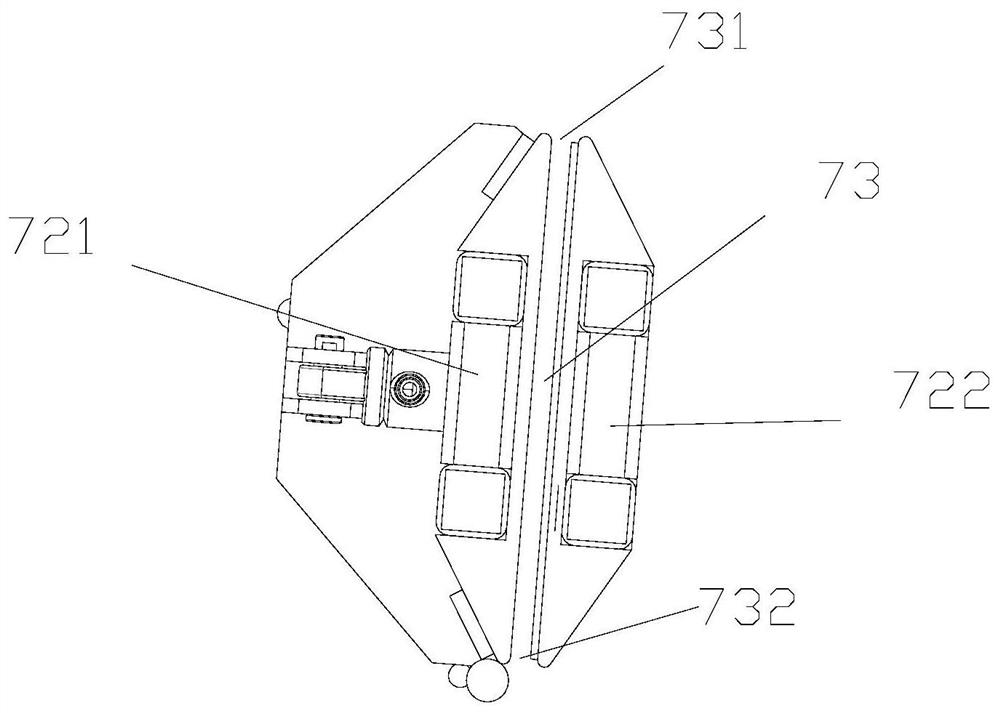

[0031] Embodiment one: if figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment provides a vertical bending machine, including an upright clamping assembly 72 and a pressing assembly, wherein the clamping assembly 72 includes a clamping seat 71 , a fixed clamp fixed on the clamping seat 71 Part 722, and the movable clamping part 721 that is arranged on the clamping seat 71 and moves closer or farther away relative to the fixed clamping part 722, and forms between the fixed clamping part 722 and the movable clamping part 721 for the reinforcement mesh to pass through. The clamping channel 73 passes, and the vertical distance of the clamping channel 73 is higher than the height of the steel mesh sheet for bending. The fixed clamping part 722 and the movable clamping part 721 in the clamping assembly 72 all adopt a flat plate structure, and two flat plates placed vertically and parallel to each other form a clamping channel 73 between the flat plates, which c...

Embodiment 2

[0036] Embodiment 2: Compared with Embodiment 1, this embodiment provides a vertical bending machine with another structure, such as Figure 5 As shown, in the vertical bending machine of this embodiment, the driving assembly is used to drive the clamping assembly 72 to rotate, and the pressing assembly is fixed. The specific structure is that the clamping assembly 72 is vertically installed on the wobble plate 79, the wobble plate 79 is arranged on the upper surface of the driven gear 751, and the output shaft of the rotating motor 78 of the drive assembly drives the driven gear 751 to rotate, and then drives the wobble plate 79. And the clamping assembly 72 on it is rotated, and the pressing rod 74 is vertically arranged outside the clamping passage 73 of the clamping assembly 72 . Since the clamping assembly 72 clamps the steel mesh sheet, during its rotation, the steel mesh sheet extending out of the clamping channel 73 contacts the pressing bar 74 and is bent under the pr...

Embodiment 3

[0037] Embodiment 3: Compared with Embodiment 1, this embodiment provides a vertical bending machine with another structure, such as Figure 6 As shown, in the vertical bending machine of this embodiment, the driving component is used to drive the clamping component 72 and the pressing component to perform relative movement, so as to bend the steel mesh sheet clamped by the clamping component 72 . The specific structure is that the driving assembly includes a first driven gear 753 located under the pressing rod 74, a second driven gear 754 located under the clamping assembly 72, and the first driven gear 753 and the second driven gear. The driving gear 752 meshed with the gear 754 respectively, and the rotating motor 78 cooperating with the rotating shaft on the driving gear 752; Rod 74, the pressing rod 74 rotates with the first driven gear 753 along the outer circumference of the clamping assembly 72, the second driven gear 754 is provided with a swing plate 79, the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com