A device for making steel cages for construction

A technology for manufacturing devices and steel cages, applied in the field of construction, can solve the problems of large labor consumption, slow labor speed, and large marking errors, and achieve the effect of large labor consumption and slow labor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

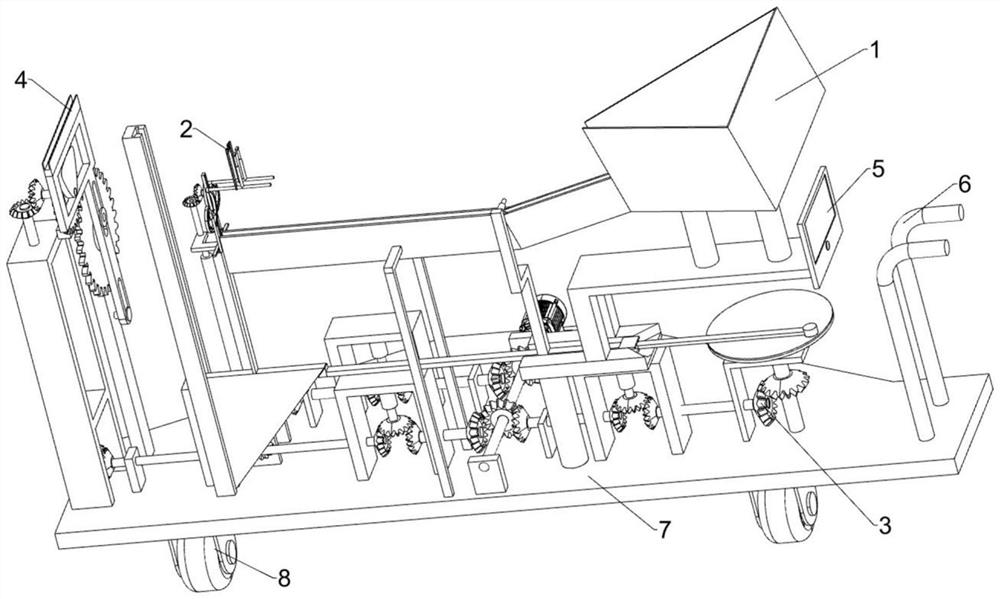

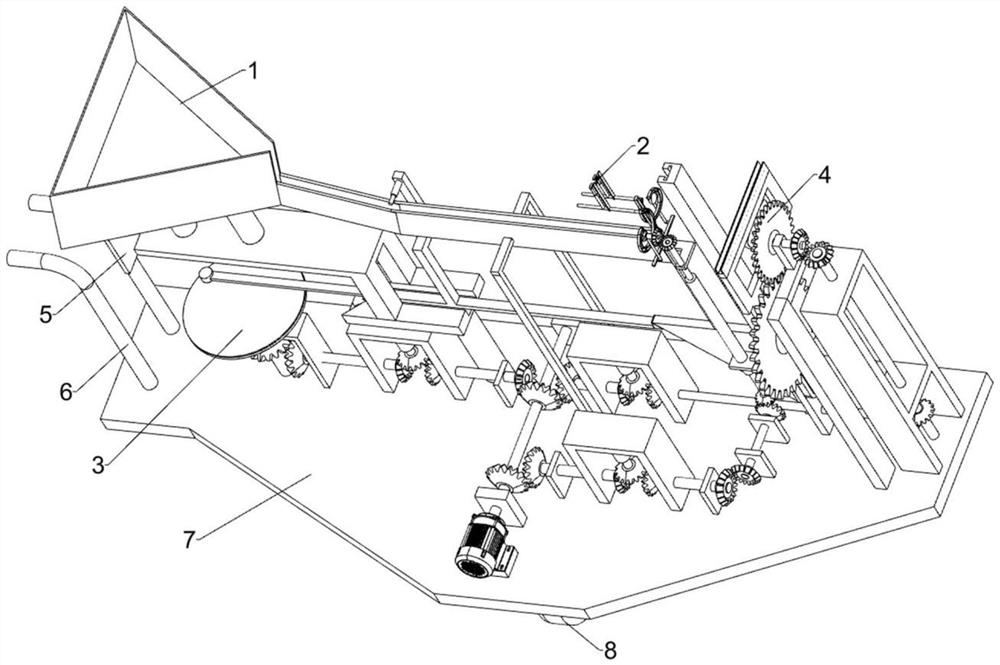

[0027] A kind of construction with steel cage making device, such as Figure 1-6 Shown, including the feeding mechanism 1, deformation mechanism 2, the push-up mechanism 3, the flip mechanism 4, the control screen 5, the handle 6, the workbench 7 and the wheel 8; the lower part of the table 7 is connected to the wheel 8; the workbench 7 is connected to the deformation mechanism 2; the workbench 7 is connected to the pushing mechanism 3; the workbench 7 is connected to the flip mechanism 4; the workbench 7 is connected to the handle 6; the feeding mechanism 1 is connected to the propellant rising mechanism 3; the feeding mechanism 1 is connected to the control screen 5; the deformation mechanism 2 is connected to the propulsion mechanism 3 The deformation mechanism 2 is connected to the flip mechanism 4; the thrust rising mechanism 3 is connected to the flip mechanism 4.

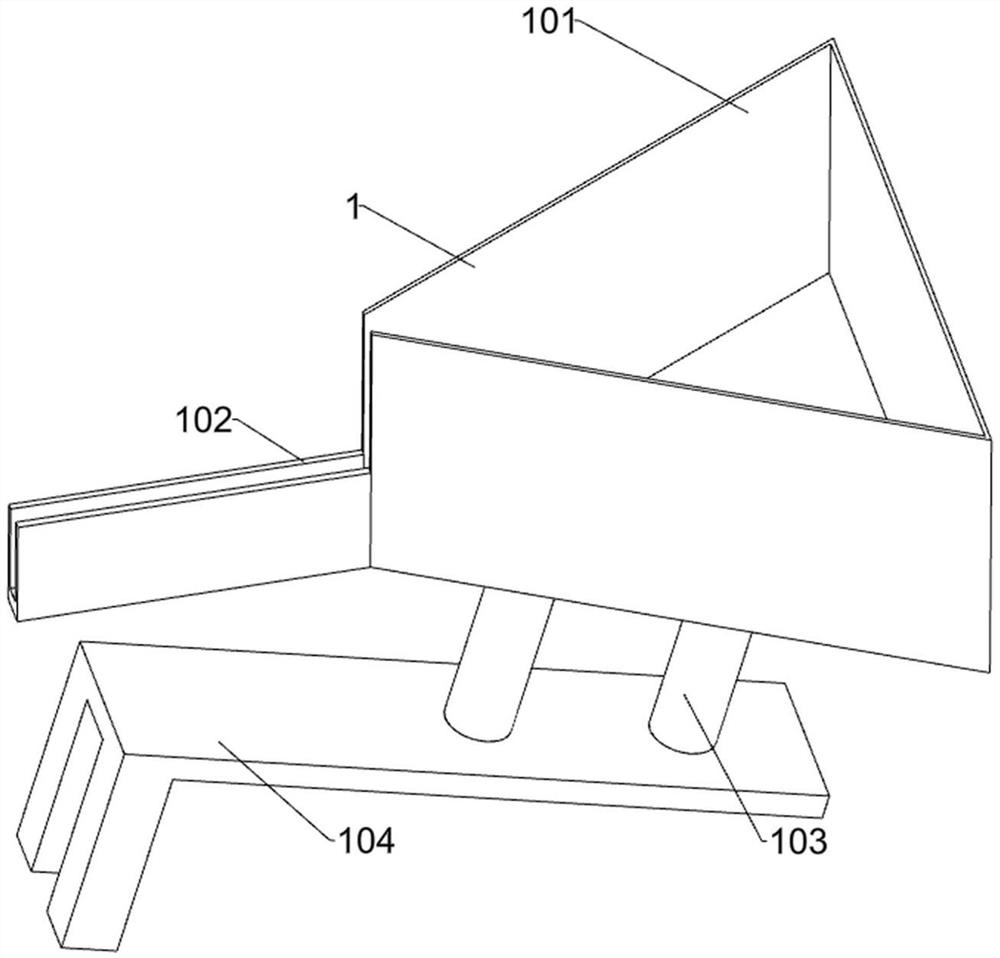

[0028] The loading mechanism 1 includes a loading box 101, a slide 102, a support column 103 and a support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com