Machine tool with optimised orientation of vibration dampers

A shock absorber, machine tool technology, applied in the field of machine tools, can solve problems with good results and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

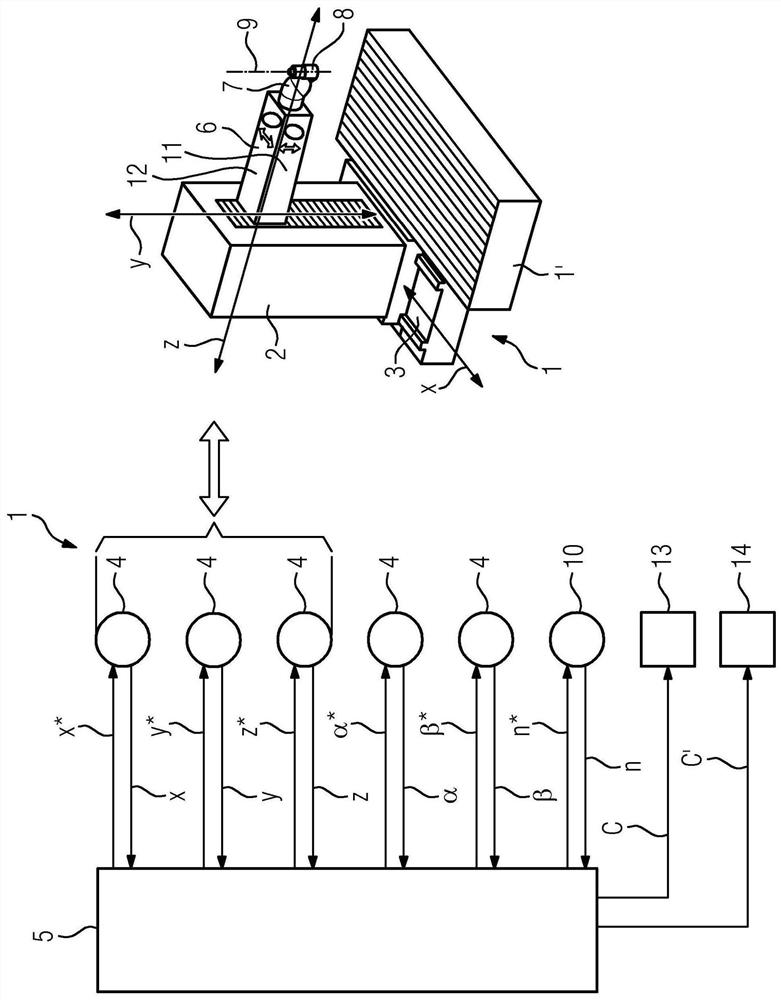

[0033] according to figure 1 , the machine tool has multiple machine elements. For example, a machine tool has a base body 1 as a machine element. On or at the base body 1 there is a workpiece table 1' as a further machine element, on which a workpiece (not shown) can be fastened. The column 2 forms another machine element. The column 2 is guided in a guide 3 of the base body 1 and is displaceable in a position-controlled manner by means of a drive 4 in the direction marked x. For this purpose, the control device 5 provides the corresponding drive 4 with a corresponding setpoint value x*.

[0034] Further guides can be arranged in the column 2 . This guide is not shown in the figures, but can be similar in design to the guide 3 . This other guide is referred to below as the outer guide. This designation is used to distinguish linguistically from another guide known as an inner guide.

[0035] The other guide, ie the inner guide, can be displaceable in a position-control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com