Die-cutting automatic material removing structure and die-cutting machine with same

An automatic, die-cutting technology, applied in metal processing and other directions, can solve the problems of manpower consumption and low efficiency, and achieve the effect of reducing the use of manpower and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

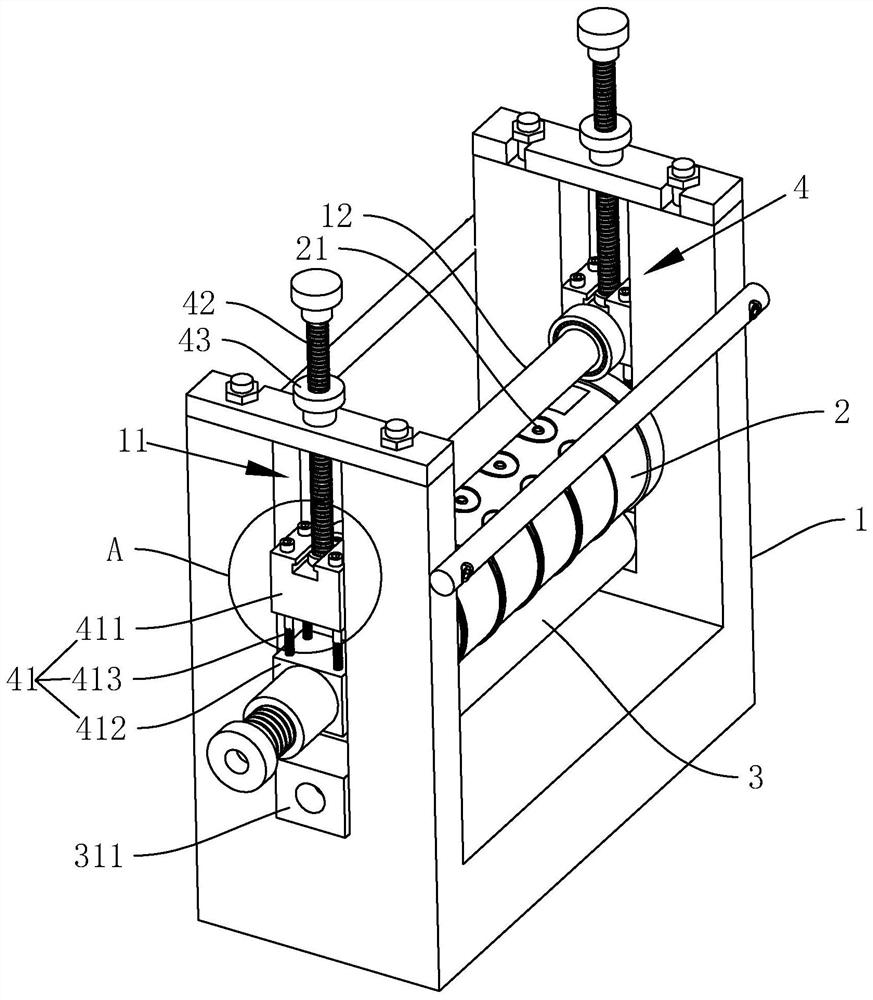

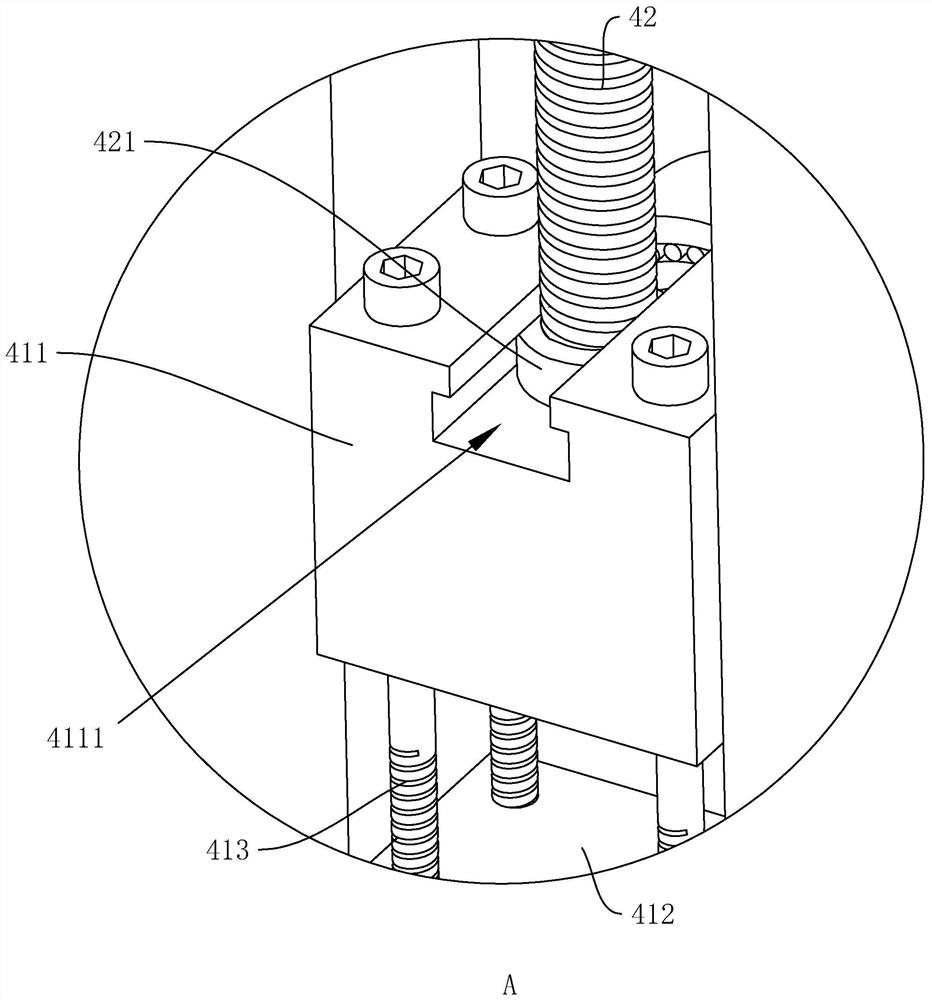

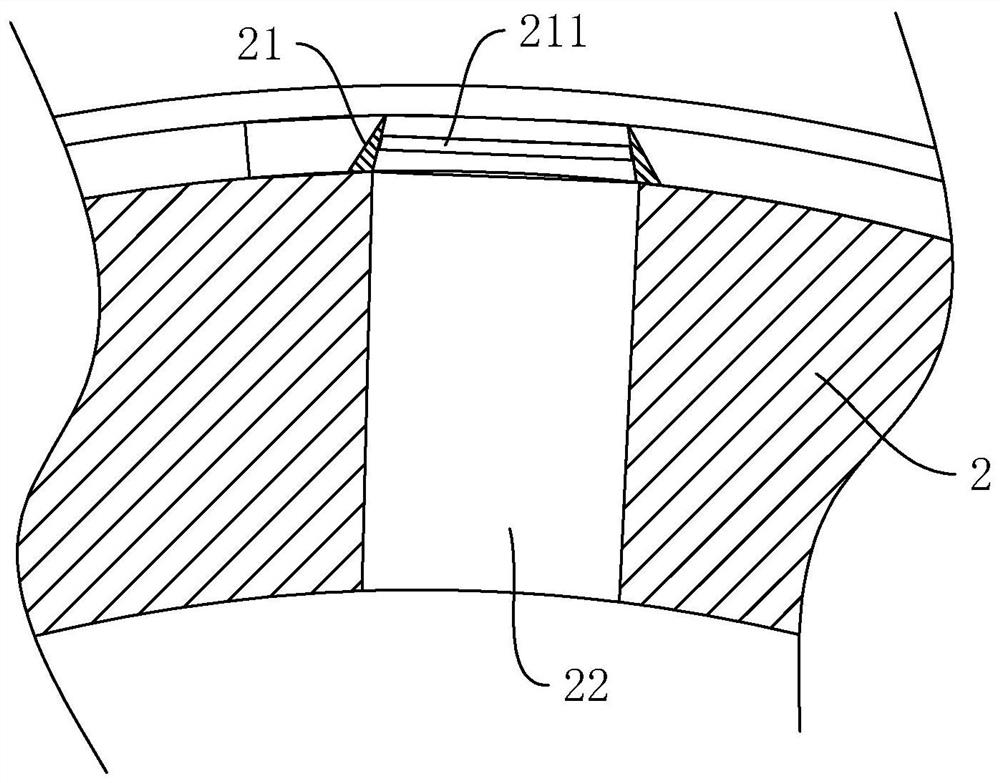

[0040] refer to figure 1 and Figure 4, is a die-cutting automatic material removal structure disclosed by the present invention, which can take away the remaining material in the hole while cutting out the hole on the label paper, and does not need to clean up the remaining material in the hole again in the later stage, reducing the manpower Use, help to improve the production efficiency of the label, the structure includes a frame 1, the upper die-cutting roller 2 and the lower pad roller 3 are rotated on the frame 1, the upper die-cutting roller 2 and the lower pad roller 3 are parallel up and down, the upper and lower The die-cutting roller 2 and the lower backing roller 3 are respectively coaxially fixed with an intermeshing gear at the same end of the shaft side surface, so that the upper die-cutting roller 2 can move together with the lower backing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com