A die-cutting automatic material removal structure and a die-cutting machine with the structure

An automatic, die-cutting technology, applied in metal processing and other directions, can solve the problems of manpower consumption and low efficiency, and achieve the effect of reducing the use of manpower and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings.

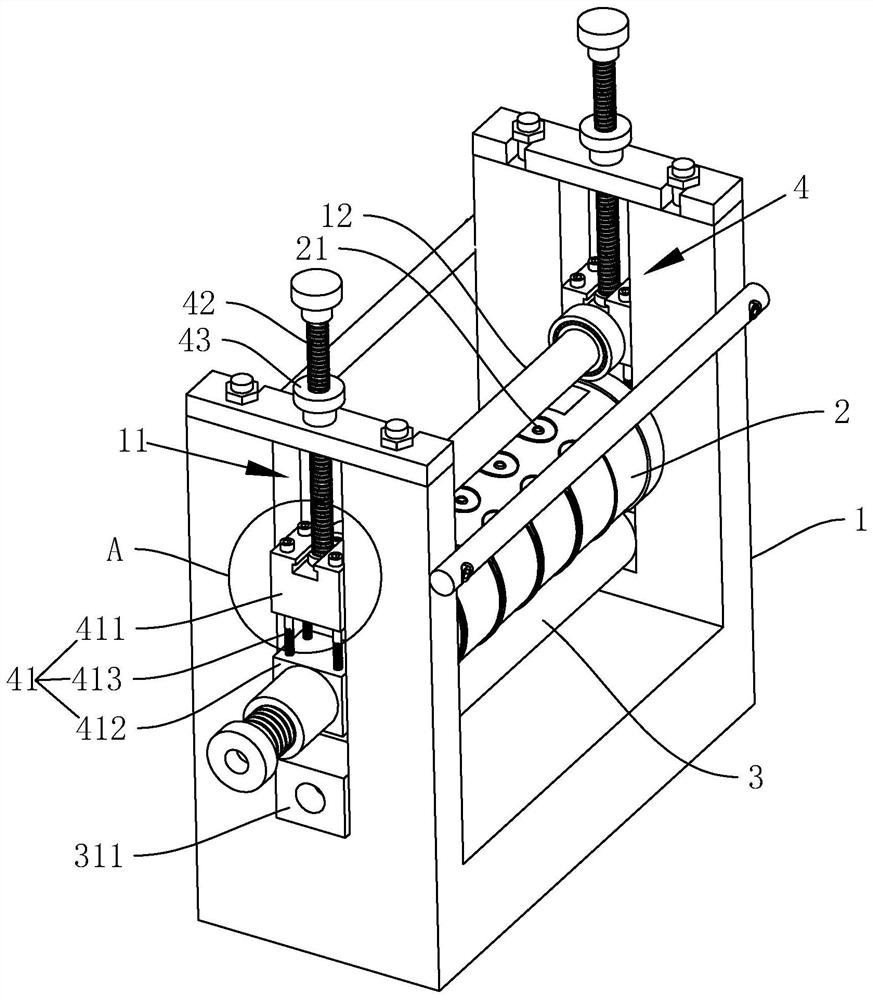

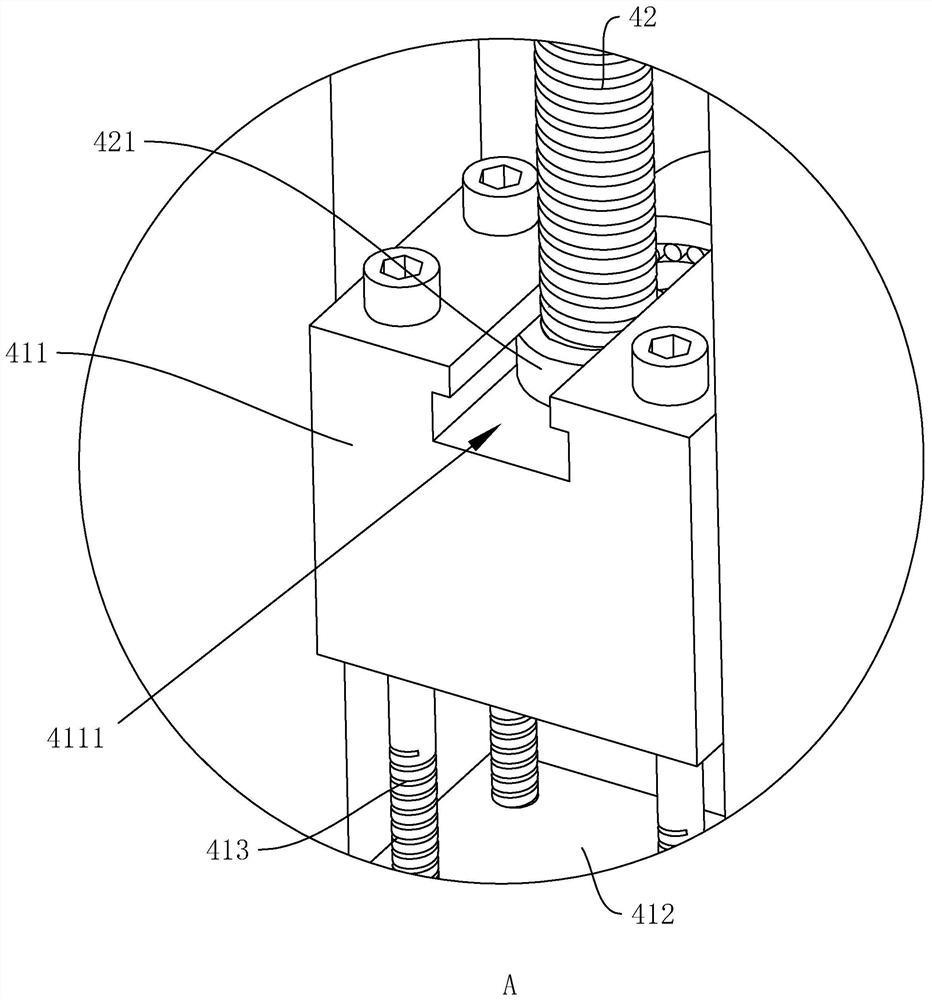

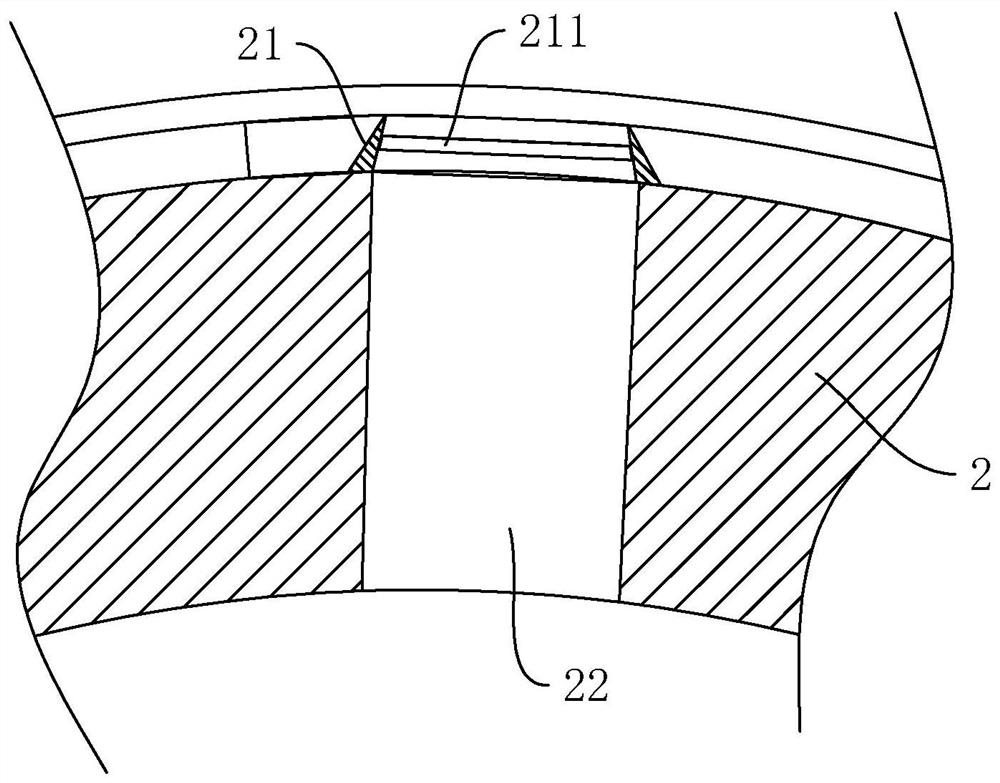

[0040] Refer figure 1 versus Figure 4 It is a die-cutting automatic fractal structure disclosed in the present invention, which can take out holes while cutting out holes on the label paper, and no need to clean up the holes in the later period, reduce human Using, it helps to increase the production efficiency of the label, the structure includes the rack 1, the rack 1 is rotated and provided with the mold cut roller 2 and the lower pad roller 3, and the upper mold cut roller 2 and the lower pad roller 3 are parallel. The die-cut roller 2 and the lower pad roller 3 are respectively engaged with each other, respectively, and the upper mold cut roller 2 can move with the lower pad roller 3; the axis of the upper mold cut roller 2 The ring die cutter 21 for cutting the label paper is welded on the side surface, and the upper mold cutting roller 2 shaft side surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com