Tire mold

A tire mold and roller technology, applied in tires, household appliances, other household appliances, etc., can solve the problems of not reaching the shape, affecting the normal use of the mold, corrosiveness, etc., and reducing the use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 6 Shown:

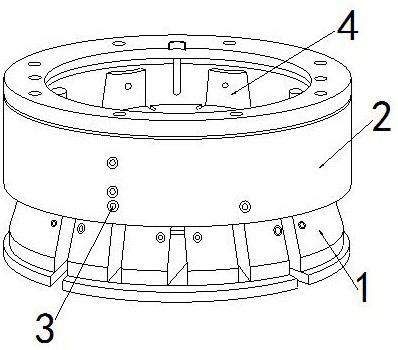

[0028] The invention provides a tire mold, the structure of which includes a lower mold 1, an upper mold 2, a vent hole 3, and a guide block 4, the outer wall of the lower mold 1 is movably engaged with the inner wall of the upper mold 2, and the vent hole 3 runs through The outer wall of the upper mold 2, and the guide block 4 is welded on the inner wall of the upper mold 2.

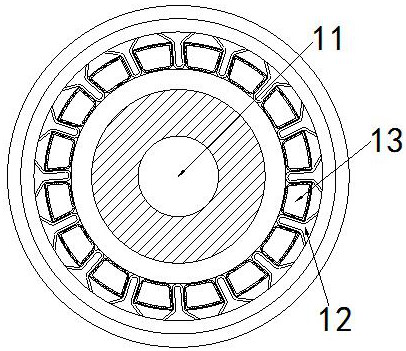

[0029] The lower mold 1 is provided with a feeding port 11, a pattern block 12, and an angle removal device 13. The feeding port 11 is set at the middle position of the lower mold 1, and the pattern block 12 is vertically fixed on the inner wall of the lower mold 1. The clip Corner clearing means 13 are mounted between the blocks 12 .

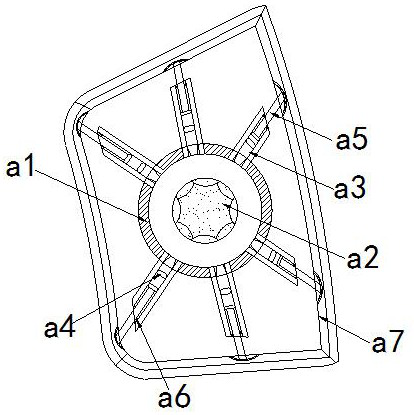

[0030] Wherein, the included angle clearing device 13 is provided with an air collecting ring a1, a silica gel block a2, an air pipe a3, a piston a4, a support rod a5, a clamping tooth a6, and a clearing ring a7...

Embodiment 2

[0037] as attached Figure 7 To attach Figure 8 Shown:

[0038] Wherein, the roller b1 is provided with a brush block e1, a connecting ring e2, a feeding groove e3, and a collection chamber e4, the brush block e1 is movably engaged with the outer wall of the roller b1 through the connecting ring e2, and the feeding groove e3 is recessed in Between the brush blocks e1, the collection chamber e4 is set inside the roller b1 and communicates with the feed trough e3. There are six brush blocks e1 in total, which is conducive to evenly moving the brush blocks between the pattern blocks 12 when they move horizontally. For the particles collected at the bottom, the connecting ring e2 has elasticity, and the elastic force generated by pressing against the bottom is beneficial to drive the brush block e1 to vibrate slightly, and accelerate the shaking of the particles on the surface of the brush block e1.

[0039] Wherein, the brush block e1 is provided with a wiper block f1, a groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com