Control method for presetting rotation number of screw of extruder

A control method and extruder technology, applied in the field of extruder control, can solve problems such as long fluctuation time, large fluctuation range of weight value, poor stability, etc., achieve fast and stable weight value, improve fluctuation of weight value, and reduce defective rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

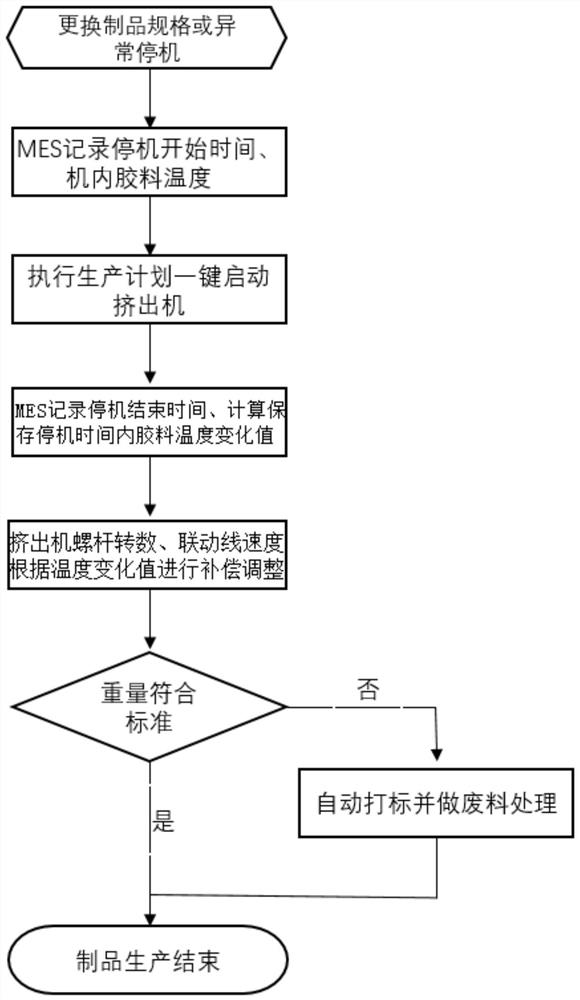

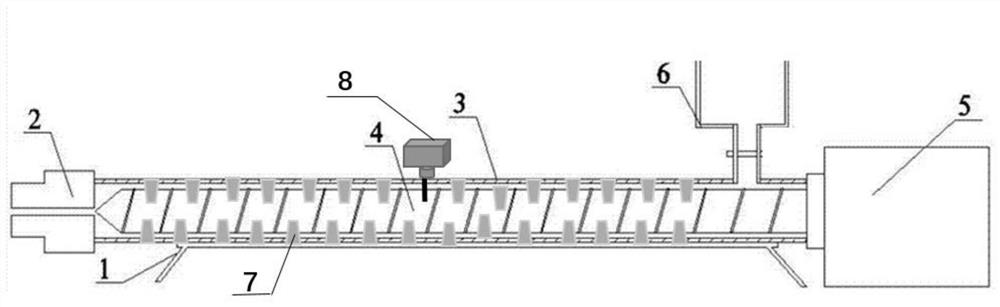

[0027] A control method for preset screw revolutions of an extrusion extruder, such as figure 2 As shown, a temperature sensor 8 for detecting the temperature of the rubber material is installed in the extruder body, and the extruder and the temperature sensor 8 are connected to the MES system. In order to accurately detect the temperature of the rubber material, the temperature sensor 8 is installed in the The plasticizing section of the extruder or the extrusion section of the extruder; the control method, such as figure 1 shown, including the following steps:

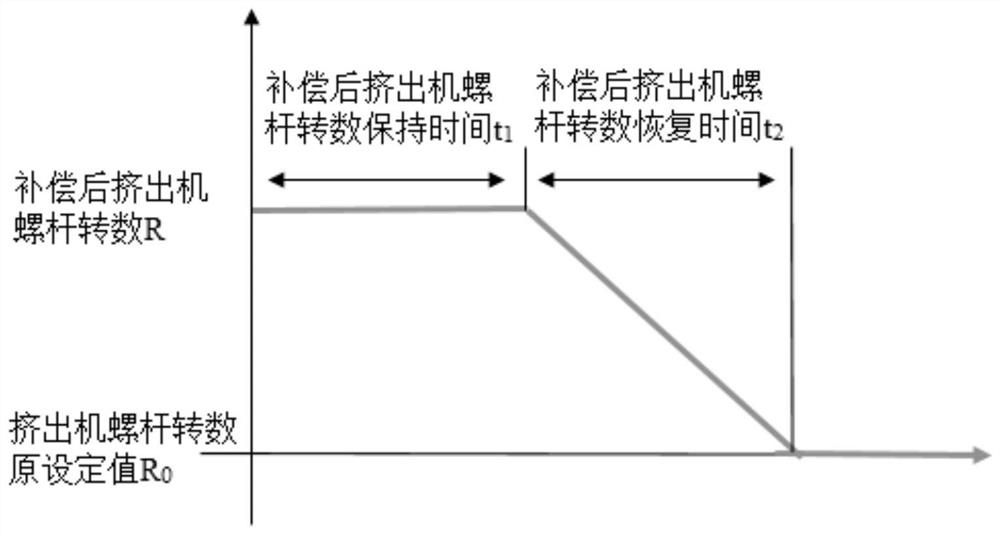

[0028] S1) The MES system detects and records the temperature of the rubber material during the shutdown period of the extruder; when the MES system detects that the extruder shutdown start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com