Patents

Literature

40results about How to "Resolution range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

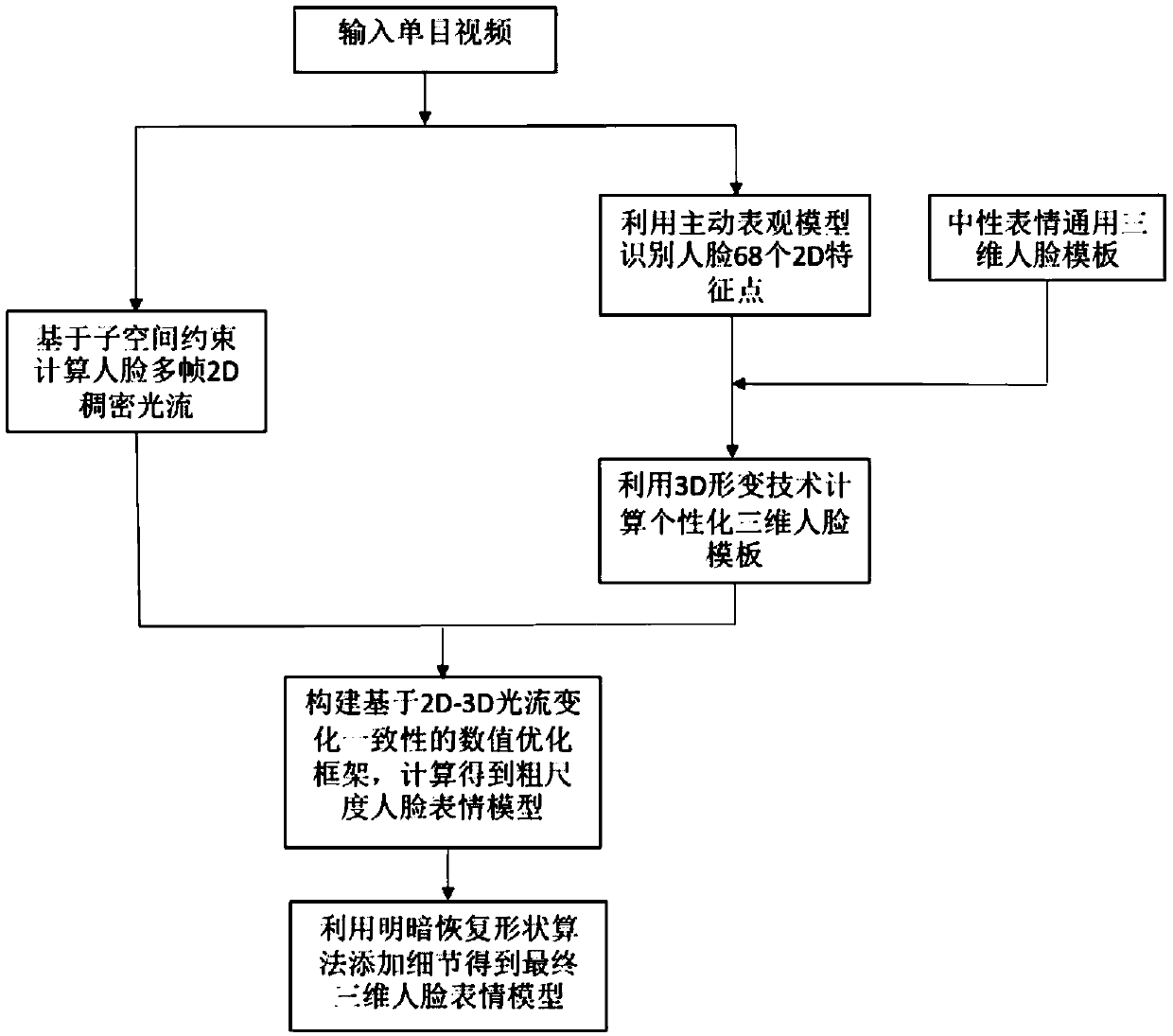

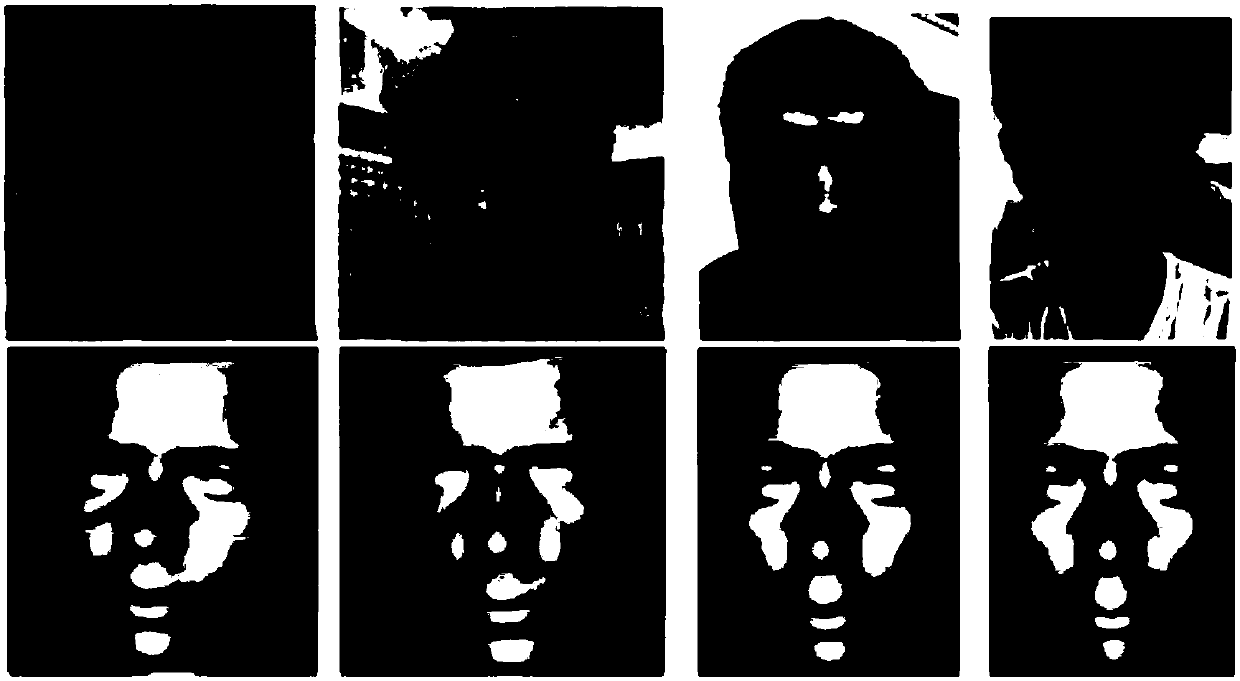

Method for reconstructing a three-dimensional facial expression model based on a monocular video

ActiveCN109584353ASolve the large amount of calculationResolution rangeImage enhancementDetails involving processing stepsPattern recognitionPersonalization

The invention discloses a method for reconstructing a three-dimensional facial expression model based on a monocular video. Extra multi-angle shooting is not needed, A universal 3D face model is directly driven from a neutral expression image frame in an input monocular video to deform so as to generate a personalized three-dimensional face template; and expressing the deformation of the three-dimensional face expressions corresponding to different frames as the change of the personalized three-dimensional face template in the 3D vertex flow of the three-dimensional space, and solving the coarse-scale geometric model of the face expressions through the consistency with the change of the 2D optical flow. While the shape accuracy of a coarse-scale reconstruction model is improved by utilizing dense optical flow, the shooting requirement of an input video is broadened, details are added on a recovered coarse-scale face model through a light and shade recovery shape technology so as to recover fine-scale face geometric data, and a three-dimensional face geometric model with high fidelity is reconstructed.

Owner:BEIHANG UNIV

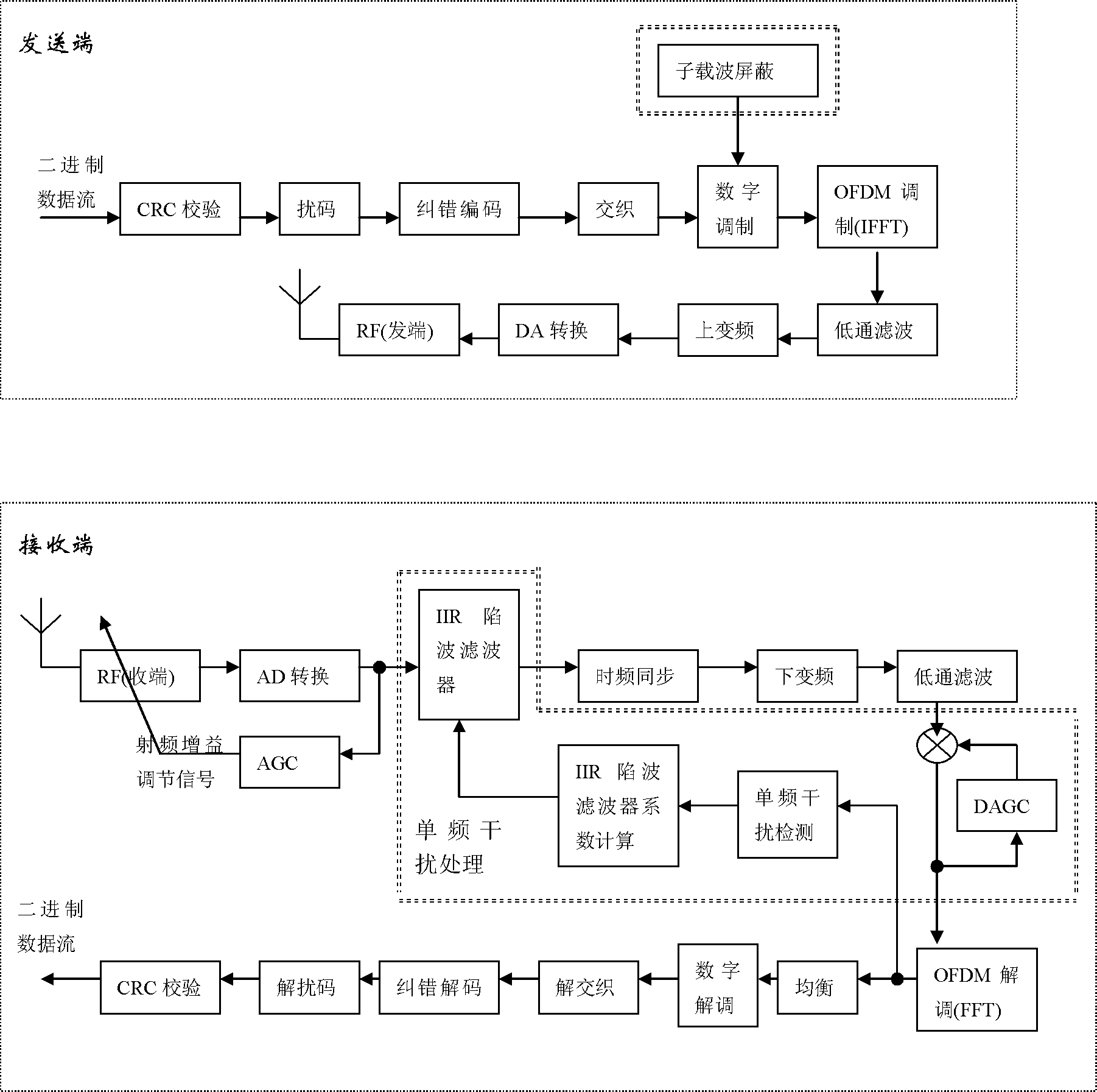

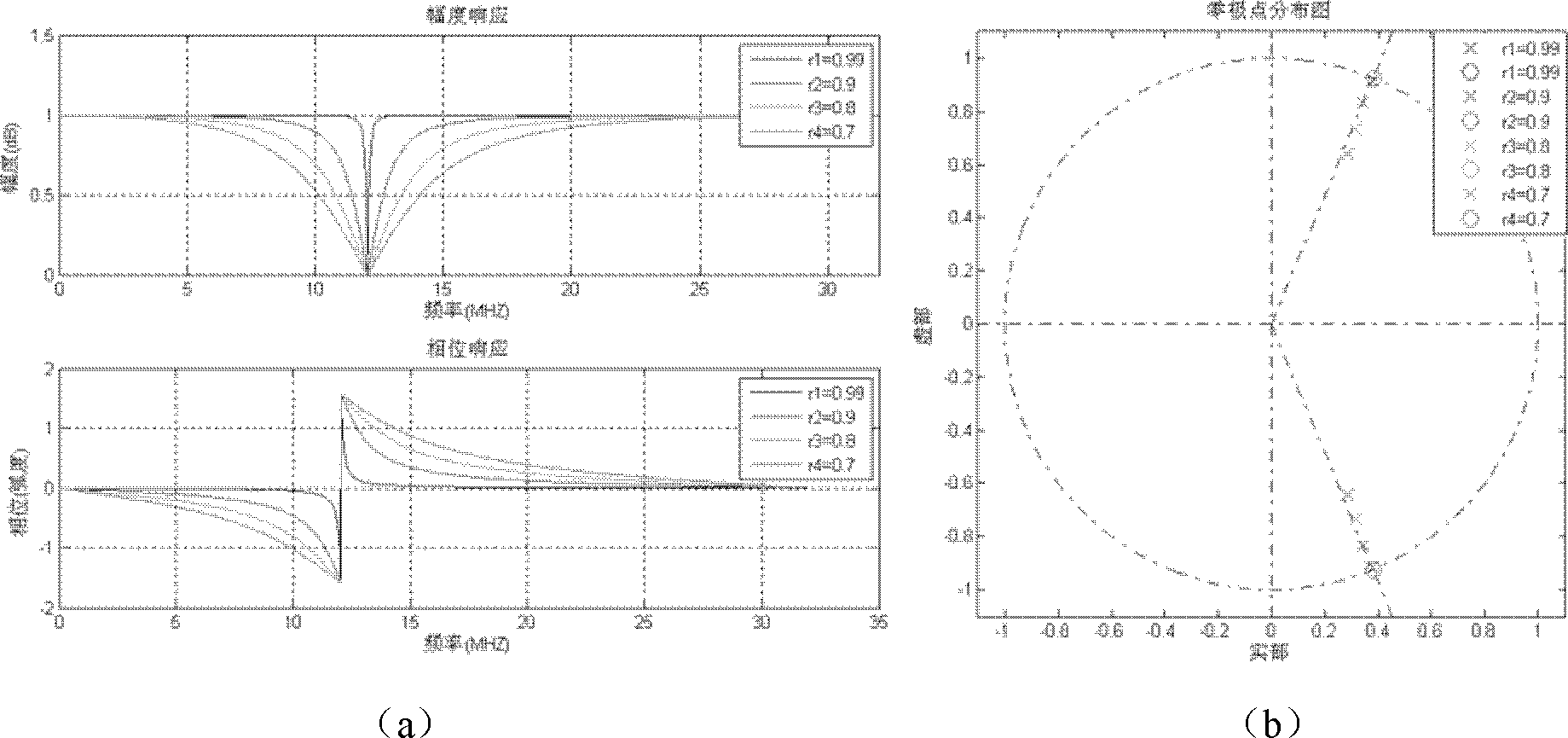

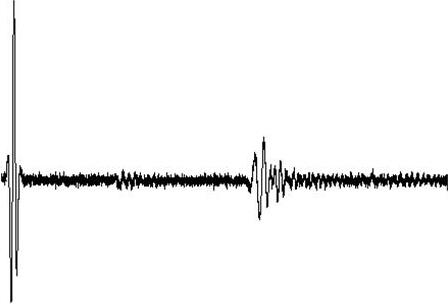

Suppression method for single-frequency interference in OFDM (Orthogonal Frequency Division Multiplexing) communication system

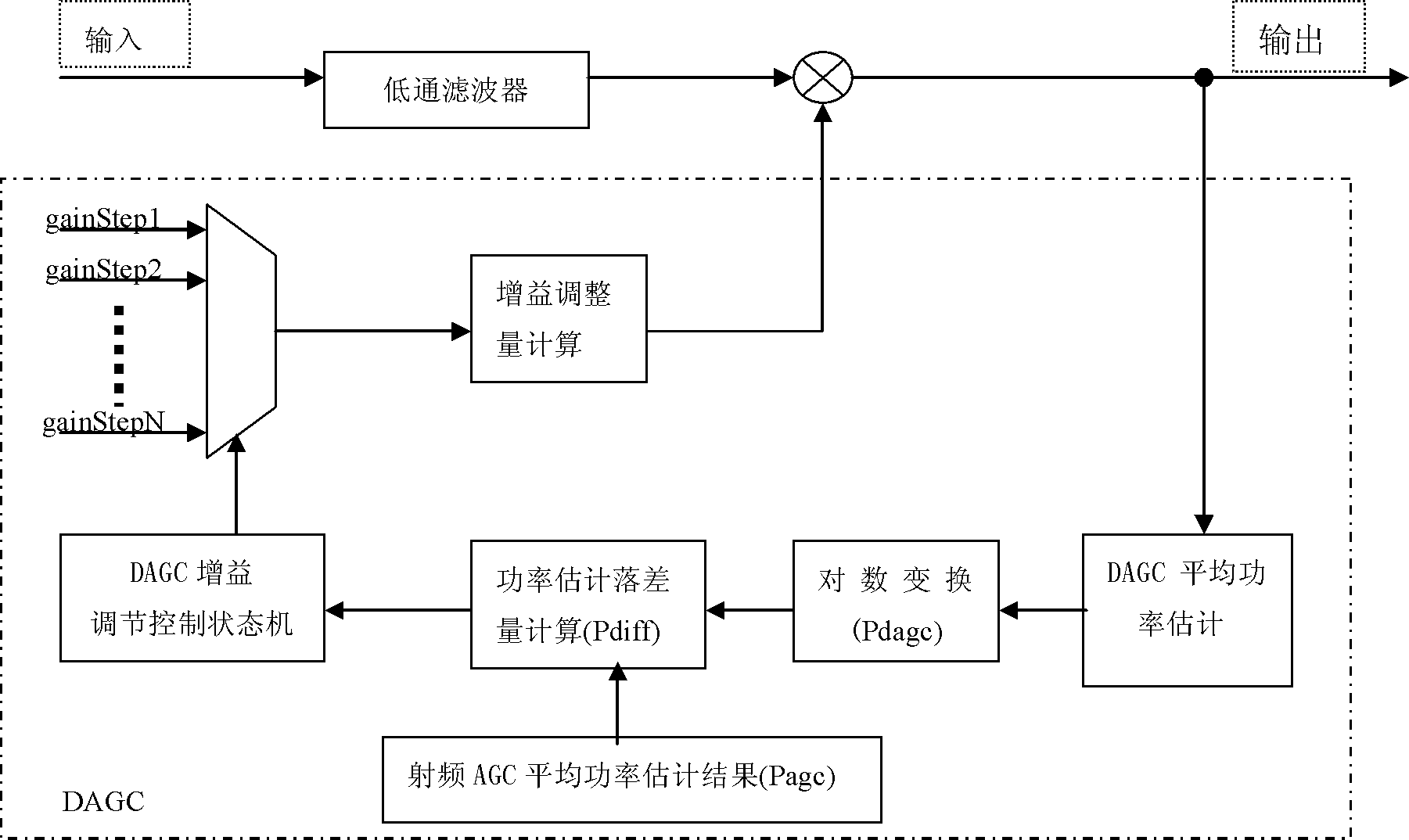

ActiveCN102811190AImprove performanceAvoiding problems with reference power determinationMulti-frequency code systemsDigital signal processingAutomatic gain control

The invention discloses a suppression method for single-frequency interference in an OFDM (Orthogonal Frequency Division Multiplexing) communication system. The suppression method comprises the following steps of: filtering the detected single-frequency interference in a time domain by an IIR (Infinite Impulse Response) notching filter through a time domain and frequency domain processing combination method, and regulating the signal power based on digital automatic gain control to ensure that the signal input powder is stabilized in the optimal input power when subsequent digital signal processes are carried out; and carrying out shielding processing on subcarriers interfered by single frequency in a frequency domain to ensure that effective data are not transmitted by the subcarriers. According to the method provided by the invention, the single-frequency interference can be effectively resisted, the single-frequency interference resistance of the OFDM communication system is improved, and the throughput of the system is improved; and when the single-frequency interference exits in the OFDM communication system, the normal operation of the system is guaranteed.

Owner:上海明波通信技术股份有限公司

Radar detection method and device based on microwave photon frequency multiplication and orthogonal demodulation

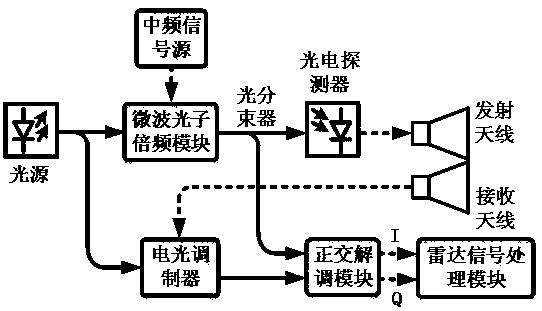

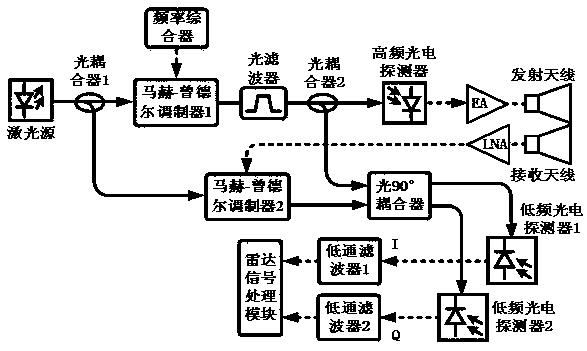

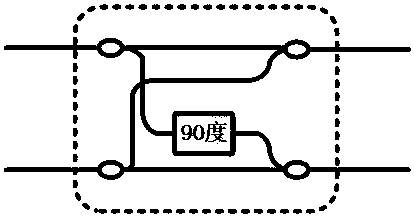

InactiveCN108802698AReal-time processingHigh distance resolutionRadio wave reradiation/reflectionMicrowaveIntermediate frequency

The invention discloses a radar detection method based on microwave photon frequency multiplication and orthogonal demodulation. The method includes: modulating an intermediate-frequency linear frequency modulation signal onto an optical carrier to generate a reservation carrier and a modulation optical signal of a unilateral second-order sideband; dividing the modulation optical signal into two branches, and emitting one optical signal after being converted into an electrical signal and serving as a radar detection signal to a target; using a target echo signal to perform electro-optical modulation on the optical carrier to acquire an optically loaded echo signal; taking the other modulation optical signal as a reference optical signal to perform orthogonal demodulation on the optically loaded echo signal to acquire two orthogonal intermediate-frequency signals carrying target information, and extracting the target information from the orthogonal intermediate-frequency signals. The invention further discloses a radar detection device based on microwave photon frequency multiplication and orthogonal demodulation. The radar detection device has the advantages of both microwave photon technology and orthogonal demodulation and is simple in realization structure and high in detection efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

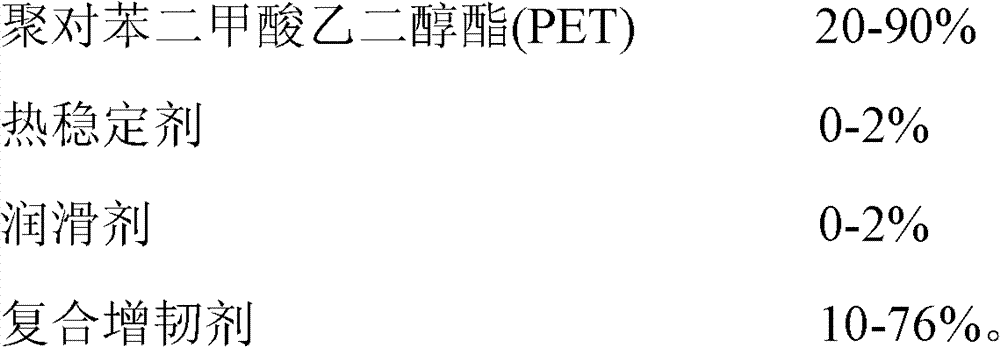

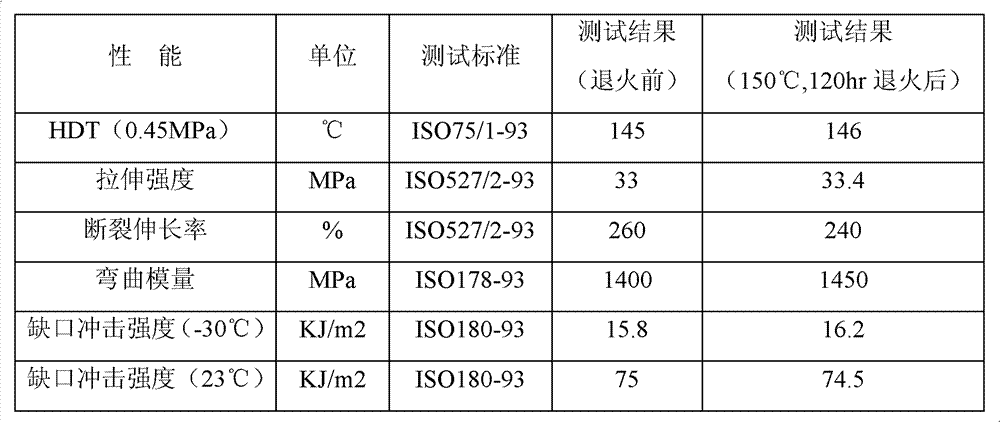

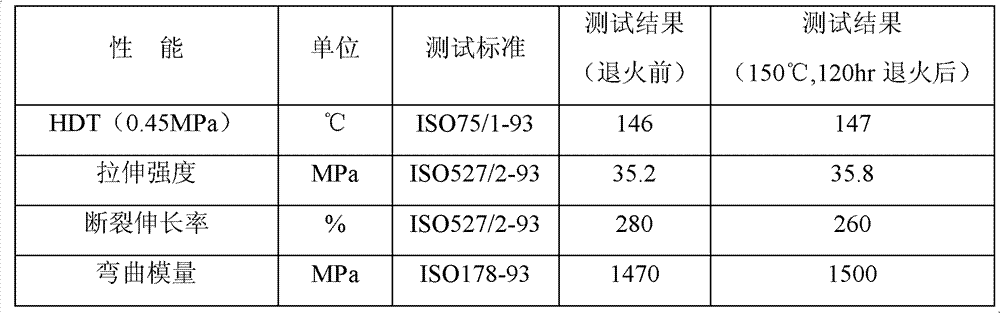

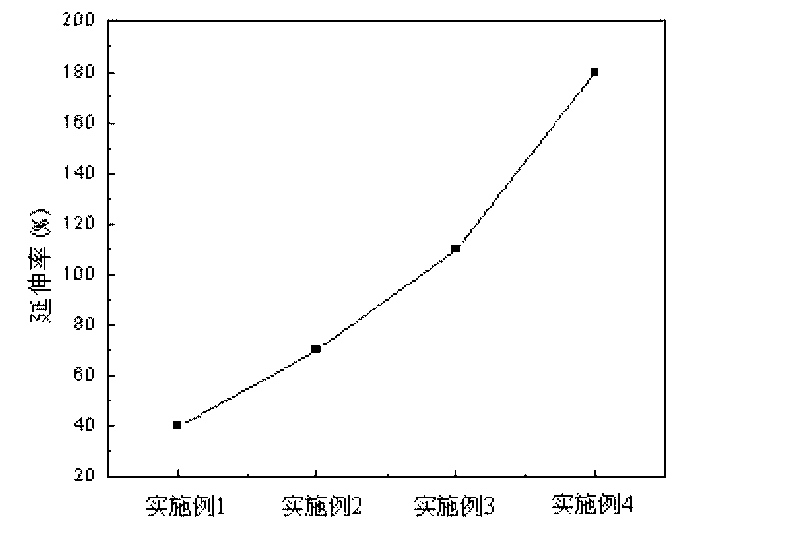

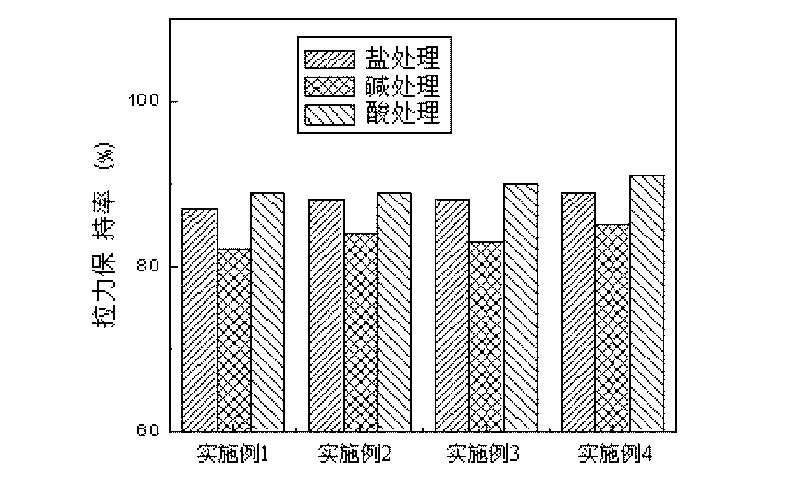

Heat-resistant super-ductility polyethylene terephthalate (PET) compound and preparation method thereof

ActiveCN103113721ASolve the malleabilityResolution rangePolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a heat-resistant super-ductility polyethylene terephthalate (PET) compound and a preparation method thereof. The heat-resistant super-ductility PET compound is prepared from the following components in percentage by weight: 20-90% of PET, 0-2% of heat stabilizer, 0-2% of lubricant and 10-76% of composite toughener. By adopting the A+B+C type composite toughener and utilizing the synergic toughening action, the invention achieves the effects of heat resistance and super ductility, solves the problem that the ductility and toughness are greatly lowered after the PET material is subjected to heat treatment, and implements high notch impact strength and super ductility. The tensile property curve of the material does not have any yield point; and after the material is annealed at 150 DEG C for 120 hours, the toughness and ductility are not influenced, and the tensile property curve also does not have any yield point. The heat-resistant super-ductility polyethylene terephthalate compound can be widely used for manufacturing automobile interior and exterior ornaments, and can protect people in the automobile in an emergency.

Owner:SHANGHAI KINGFA SCI & TECH +1

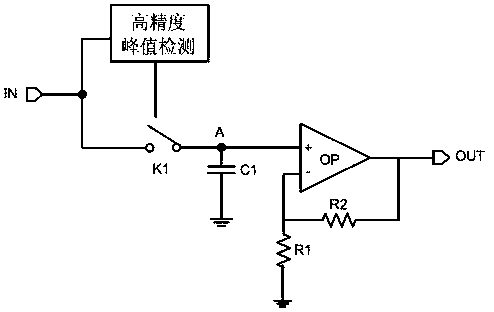

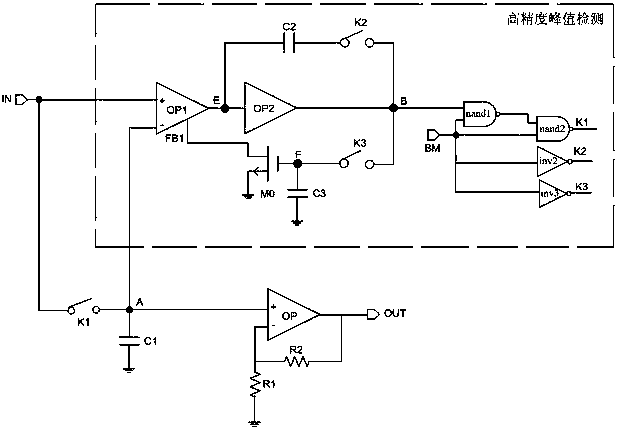

Narrow-pulse peak sampling hold circuit

PendingCN108809278AResolution rangeSolve the problem of keeping the peak voltage value lowPulse manipulationSmall amplitudeNegative feedback

The invention discloses a narrow-pulse peak sampling hold circuit. The narrow-pulse peak sampling hold circuit is characterized in that a narrow pulse IN is detected by a high-precision peak detectionmodule and is input into a point A through a first switch K1 controlled by the high-precision peak detection module, the point A is grounded through a first capacitor, and meanwhile, the output voltage OUT is taken as final output sampling hold voltage after a signal of the point A passes through a total operational amplifier OP; after the high-precision peak detection module detects the peak voltage of the narrow pulse IN, the first switch K1 is controlled to be disconnected, so that the peak voltage is held at the point A. According to the narrow-pulse peak sampling hold circuit, a method of presetting a second gain stage static working point of a comparator through the local negative feedback is provided, so that a problem that a traditional peak hold circuit cannot hold a peak value of a small-amplitude narrow-pulse signal or hold a lower peak voltage value is solved, and the loss of the held voltage peak is smaller.

Owner:NORTH ELECTRON RES INST ANHUI CO LTD

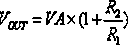

Production method for linear alkylbenzenes

ActiveCN108341735ASolve the scarcityAbundant sources of raw materialsDistillation purification/separationCatalystsAlkaneReaction temperature

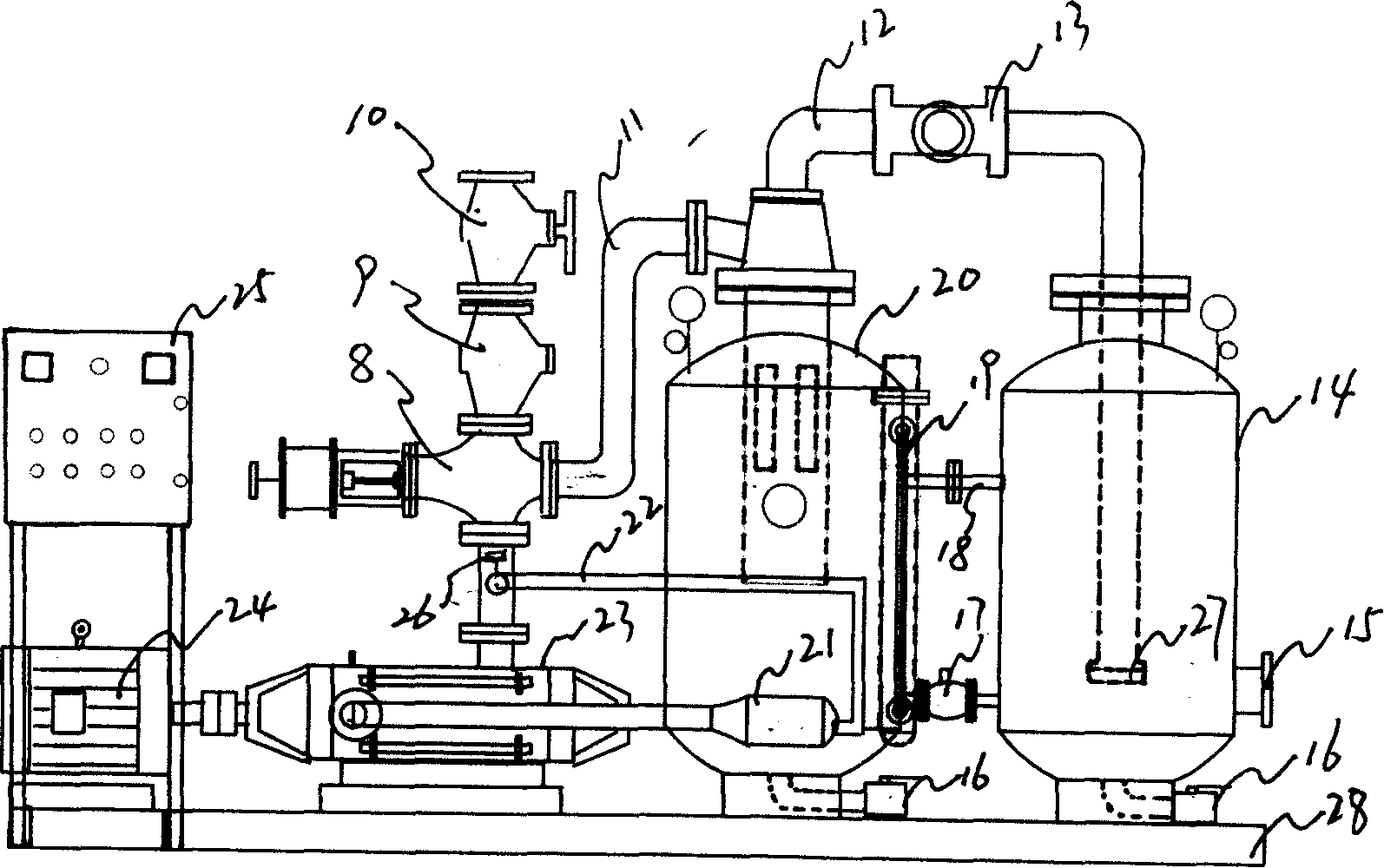

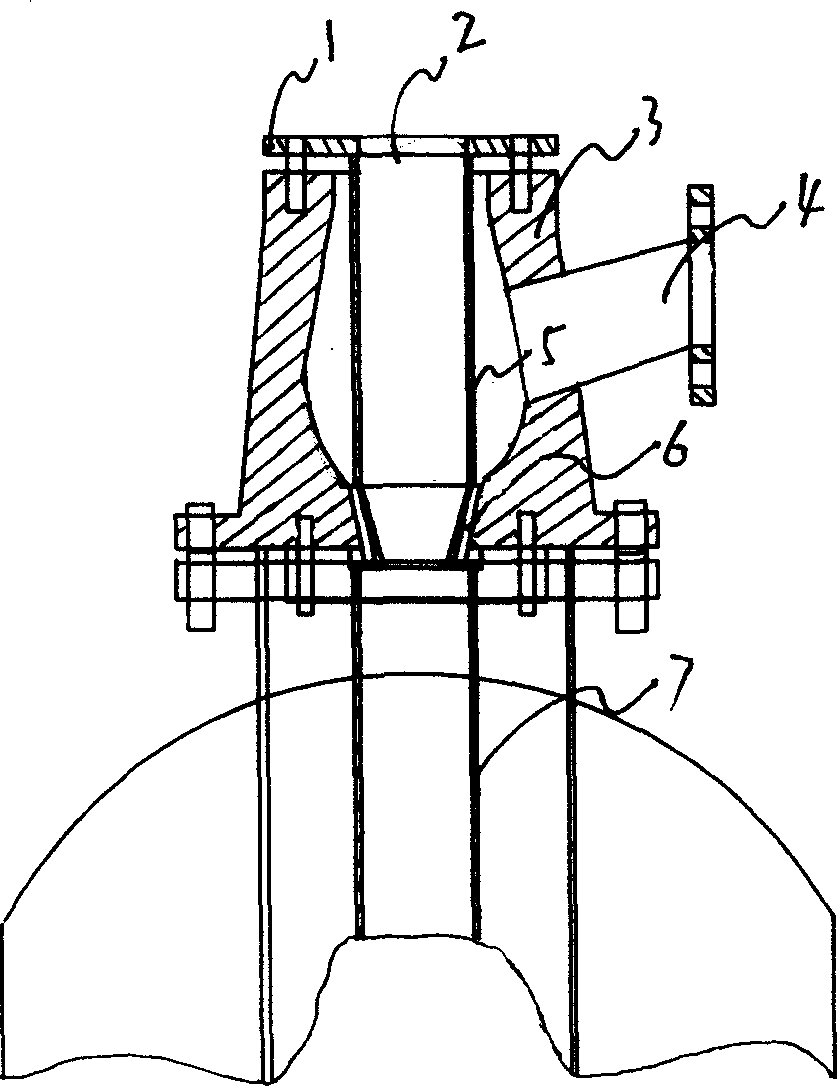

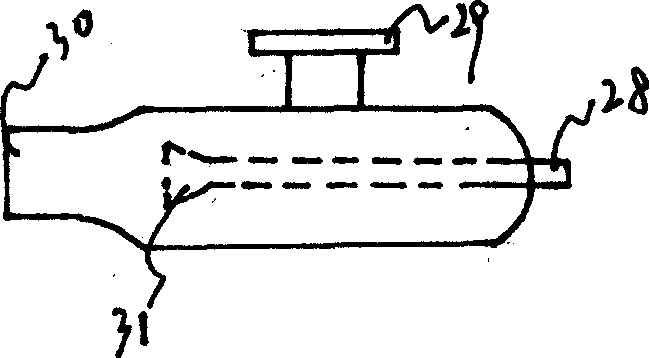

The invention discloses a production method and equipment for linear alkylbenzenes which are developed by taking Fischer-Tropsch synthetic oil as raw materials. The method is used for producing C10-C13 linear alkylbenzenes by carrying out a liquid-phase reaction on the raw materials, namely n-alkane olefins containing 2-20 carbon atoms in the Fischer-Tropsch synthetic oil under the conditions thatthe reaction temperature is 35-70 DEG C, the reaction pressure is 0.4-1MPa and the benzene / alkene molar ratio is (4-12):1. By using the production method and equipment, firstly, the aim of ''three reduction'' including energy consumption reduction, investment reduction and processing cost reduction is achieved better; and secondly, the problem that the raw materials for producing the linear alkylbenzenes are scarce at present is solved better. The production method and equipment can be directly used for industrial production of the linear alkylbenzenes. The method comprises the steps: separating n-alkane olefins from the Fischer-Tropsch synthetic oil serving as a raw material, carrying out refining to remove higher alcohols, and then, carrying out an alkylation reaction. The production method is characterized by comprising the steps: making the raw material enter a pretreatment dividing wall column, making n-alkane olefins from which 10-13 carbon atoms are separated enter an extraction column, removing alkanes of the higher alcohols, then, carrying out mixing with benzene and hydrofluoric acid, next, making the mixture enter an alkylation reactor, and making a reaction product sequentially pass through a deacidification column, a debenzolization column and a product dividing wall column to obtain the high-purity C10-C13 linear alkylbenzenes.

Owner:南京三新化工科技有限公司

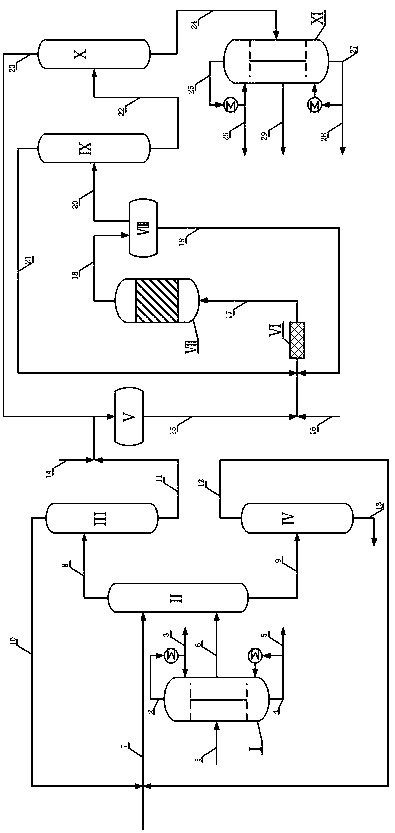

Blended composite modified asphalt and preparation method thereof

InactiveCN101717587AImprove waterproof performanceResolution rangeProductsReagentsBituminous waterproofingMetallurgy

The invention discloses blended composite modified asphalt, which comprises the following components in percentage by mass: 2 to 6 percent of waste packing polymer EVA, 2 to 15 percent of waste tire powder, 76.5 to 90.5 percent of matrix asphalt, 0.02 to 0.5 percent of cross linker and 1 to 2 percent of catalyst. A preparation method for the blended composite modified asphalt comprises the following steps: firstly, weighing 2 to 6 percent of waste packing polymer EVA, 2 to 15 percent of waste tire powder, 76.5 to 90.5 percent of matrix asphalt, 0.02 to 0.5 percent of cross linker and 1 to 2 percent of catalyst in percentage by mass; and smelting the matrix asphalt at the temperature of between 150 and 180 DEG C, adding the waste packing polymer EVA and the waste tire powder into the smelted matrix asphalt, keeping the temperature constant, manually stirring the mixture for 20 to 40 minutes, adding the cross linker and the catalyst into the mixture, and stirring the mixture for 100 to 120 minutes by a shearing machine to obtain the blended composite modified asphalt. The blended composite modified asphalt and the preparation method thereof of the invention solve the problems of large consumption of waterproof material polymer and complex equipment in the physical modification method for preparing the modified asphalt.

Owner:XIAN UNIV OF TECH

Heat insulating and flame retardant felt

The present invention provides a heat insulating and flame retardant felt, which is mainly prepared from high density polyethylene, added with glass fiber, wollastonite, montmorillonite, potassium titanate, zinc oxide, an ethylene-propylene-diene monomer, butadiene-acrylonitrile rubber, styrene-butadiene-styrene terpolymer, ethane-octylene copolymer, carbon nano-tube, calcium carbonate superfine powder, polypropylene grafting maleic anhydride, 2, 4, 6-tert-butyl phenol, and a colouring agent. Ingredients of the mixed materials for preparing the heat insulating and flame retardant felt are appropriate, which can overcome problems of poor toughness, low heat resistant grade and so on existed in normal polyethylene composite material felts.

Owner:ZHEJIANG NORMAL UNIVERSITY

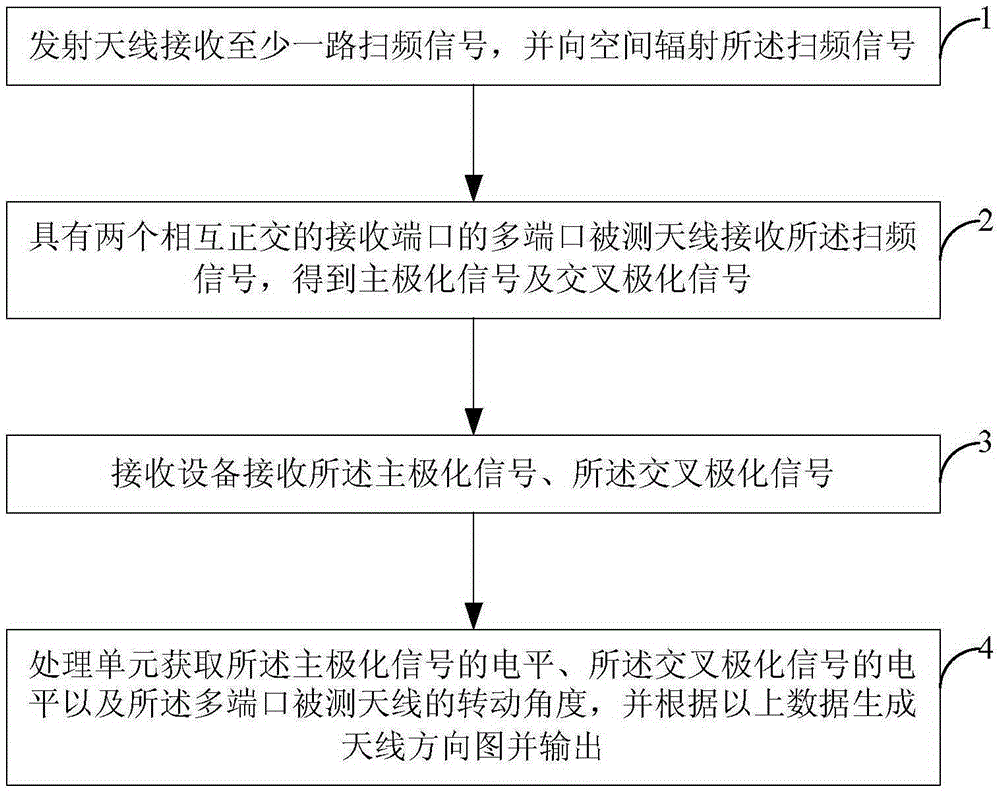

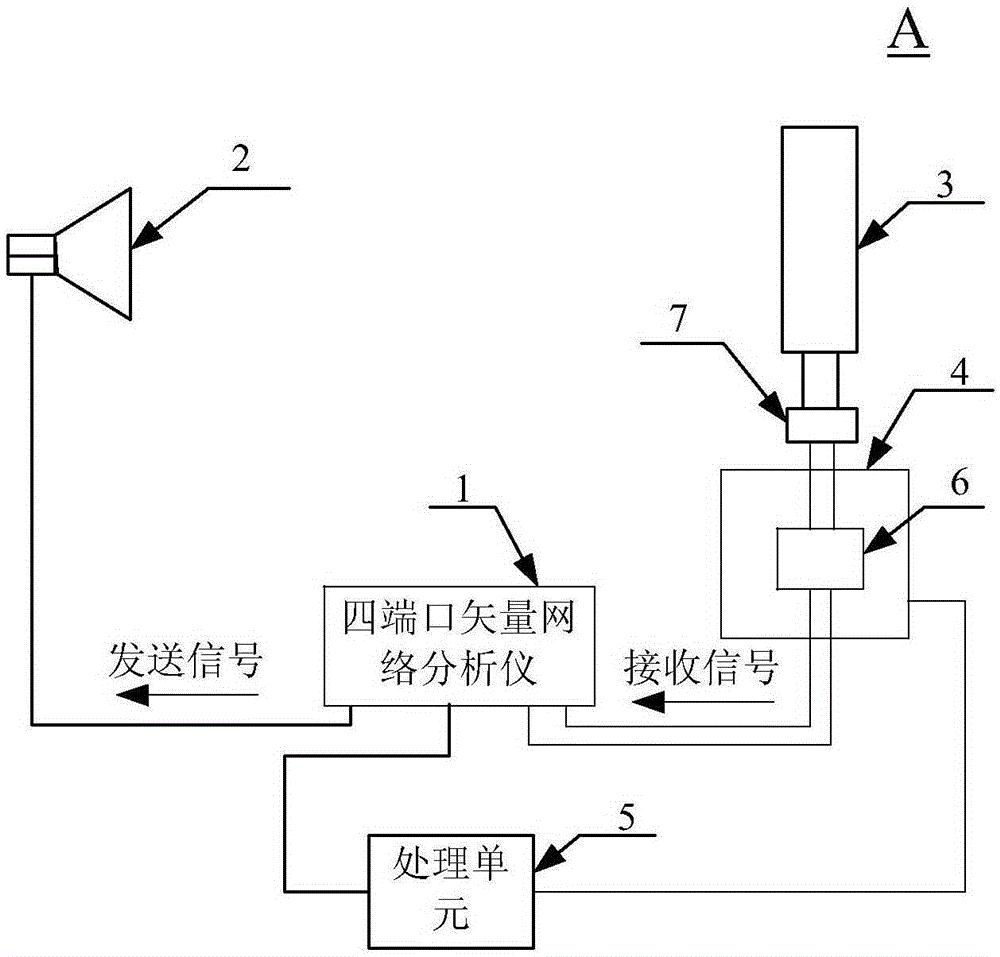

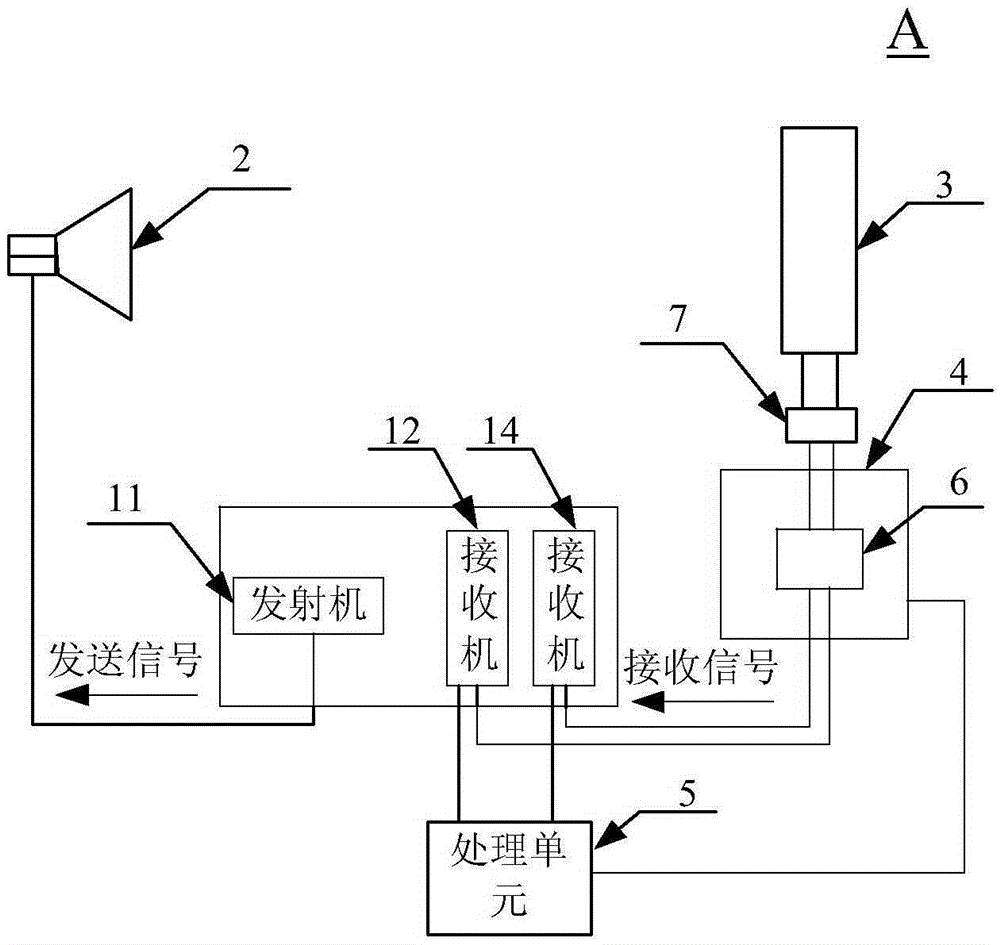

Frequency sweep measurement method and frequency sweep measurement system based on diversity concept

ActiveCN105353230AResolution rangeSolve inherent antenna measurement problems such as phaseAntenna radiation diagramsCross polarizationDiversity scheme

The invention provides a frequency sweep measurement method and frequency sweep measurement system based on a diversity concept. The frequency sweep measurement method comprises the following steps: an emission frequency receiving at least one frequency sweep signals, and radiating the frequency sweep signals to space; a multi-port detected antenna with two mutually orthogonal receiving ports receiving the frequency sweep signals, and obtaining main polarization signals and cross polarization signal; a receiving device receiving the main polarization signals and the cross polarization signals; and a processing unit obtaining level of the main polarization signals, the level of the cross polarization signals and an rotation angle of the multi-port detected antenna, and generating and outputting an antenna direction map according to the level of the main polarization signals, the level of the cross polarization signals and the rotation angle of the multi-port detected antenna.

Owner:CHINA ACADEMY OF INFORMATION & COMM +1

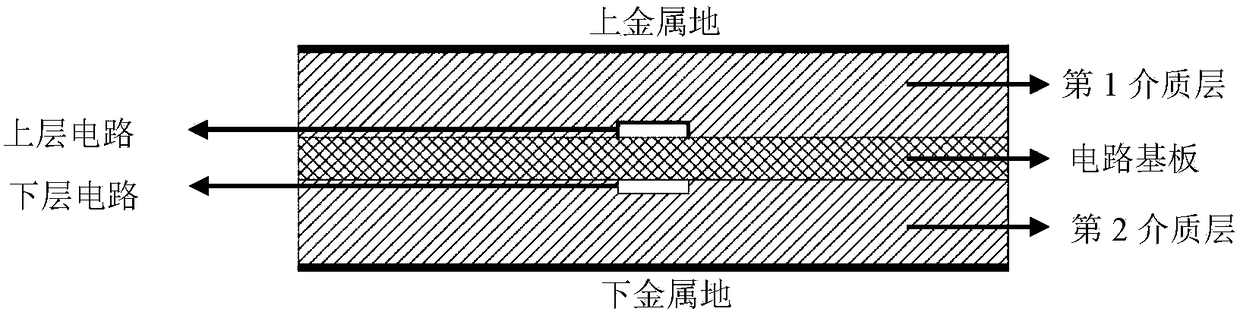

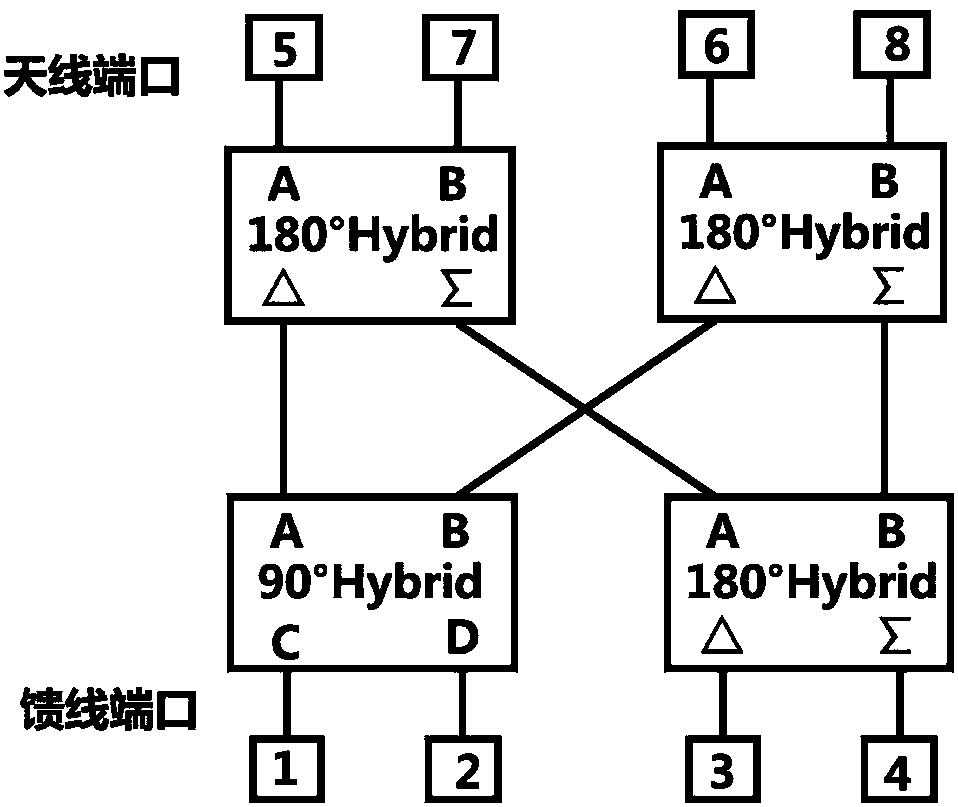

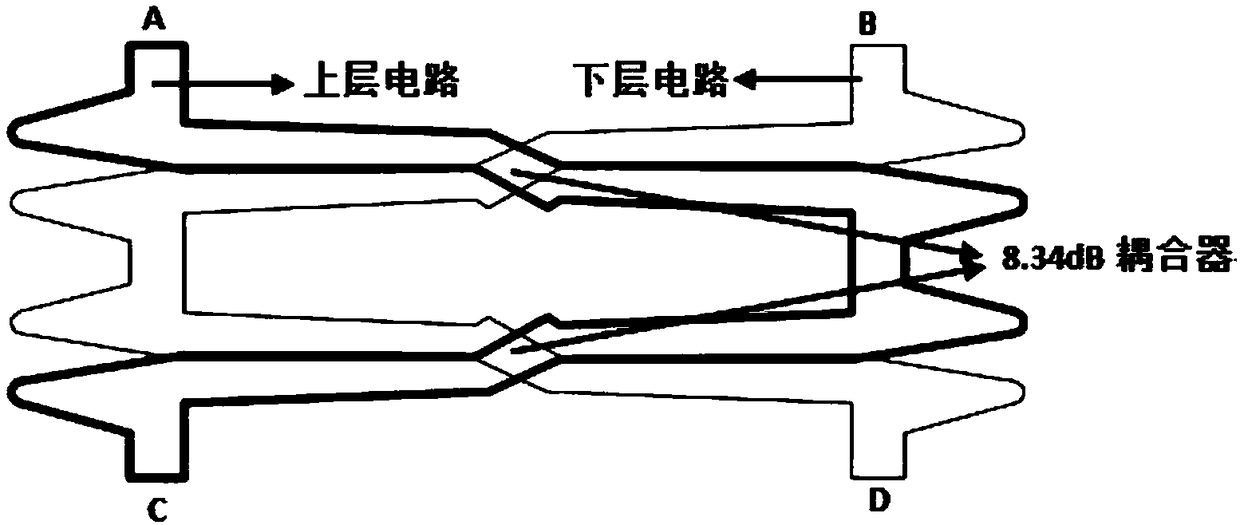

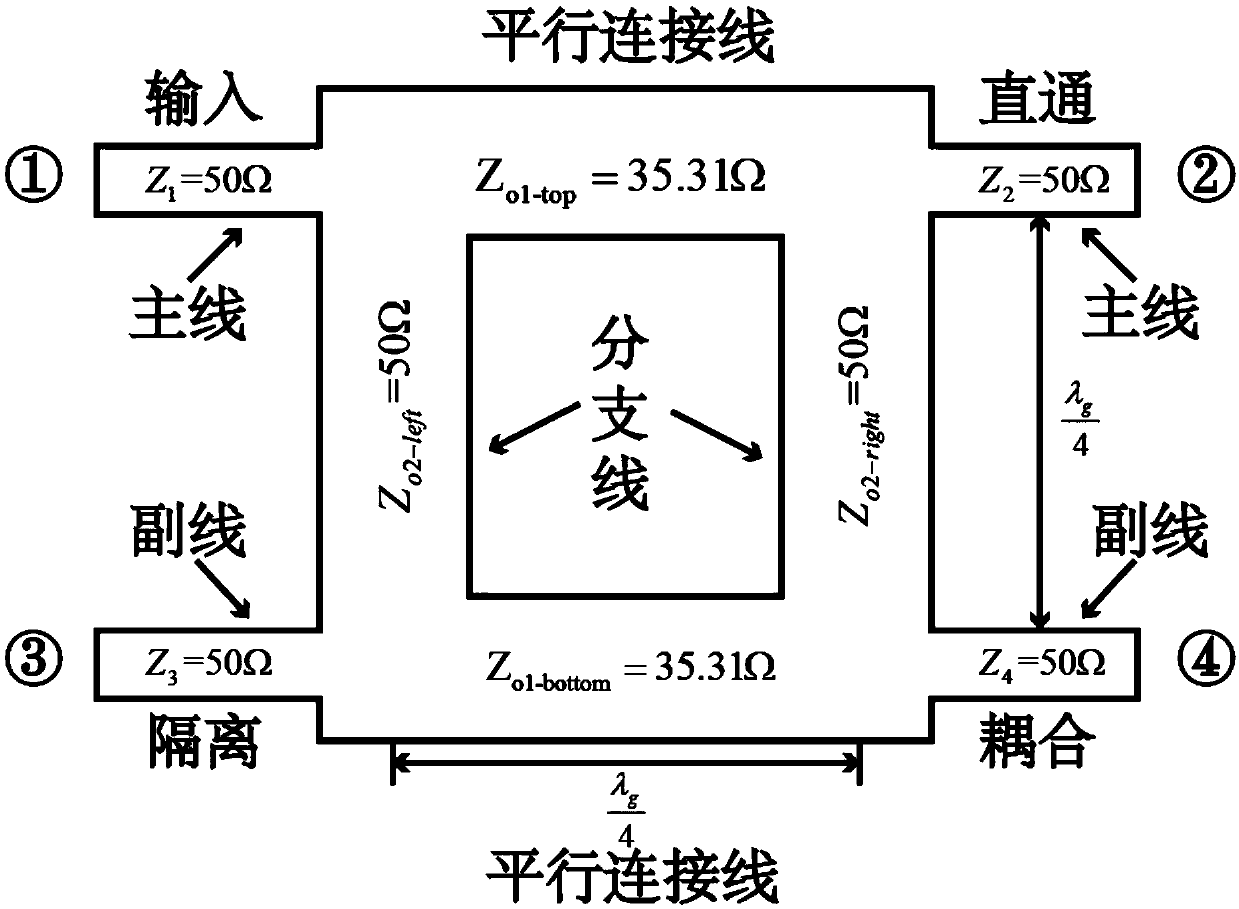

Broadband multilayer microstrip Butler beamforming network matrix device

The invention discloses a broadband multilayer microstrip Butler beamforming network matrix device, and belongs to the technical field of electronic communication in order to solve the defects, such as a narrow operating frequency, a large port phase shift error, and poor port amplitude flatness, of a current Butler matrix. The broadband multilayer microstrip Butler beamforming network matrix device is easy to manufacture, low in cost, high in port phase shift accuracy, small in port amplitude fluctuation, low in loss, wide in operating frequency and high in port isolation degree, can meet therequirements of modern civilian mobile communication systems and military radar systems for new-generation multi-beam array antennas and antenna testing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

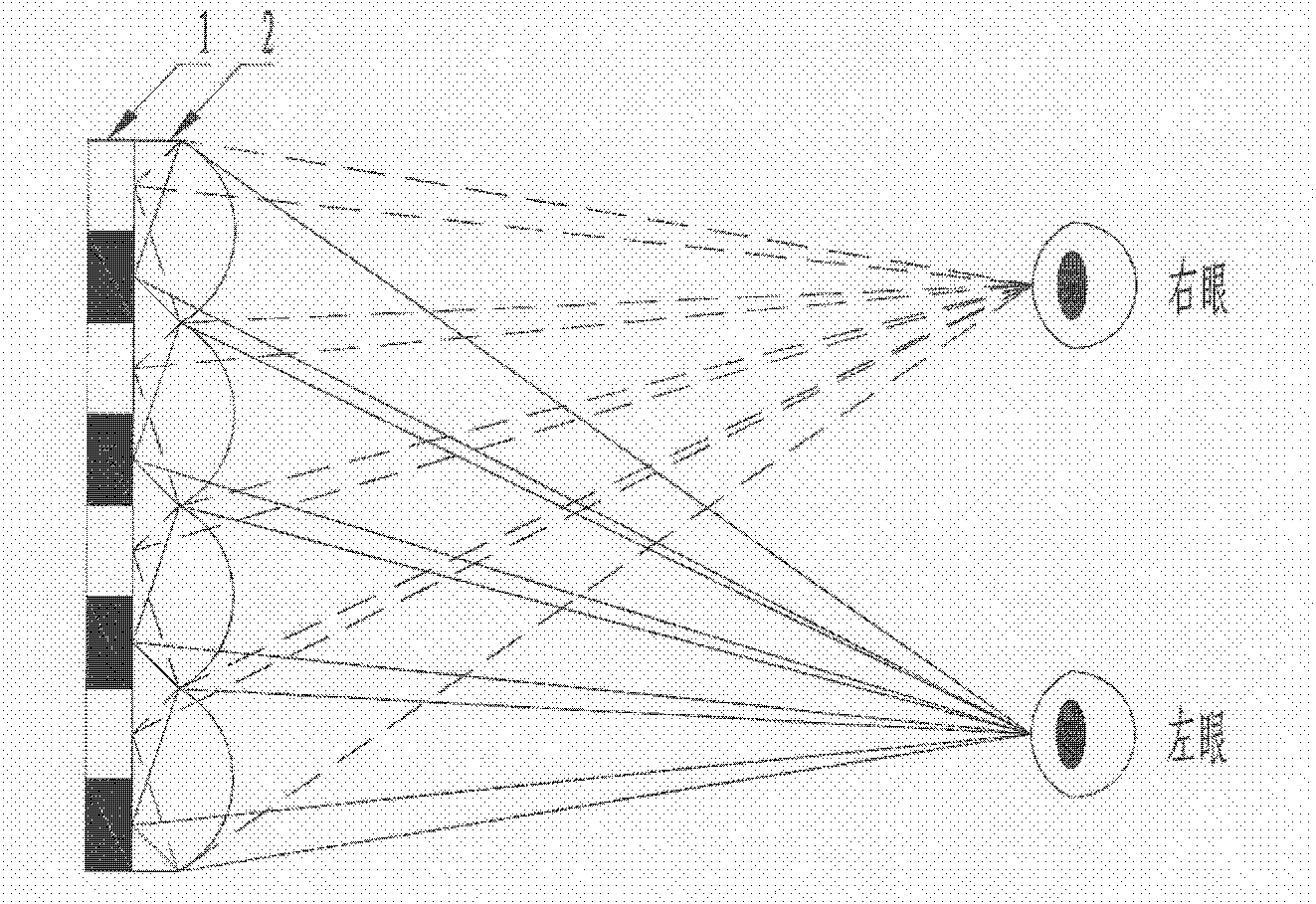

Stereoscopic large screen based on cylindrical lens luminous tube

InactiveCN102183845AAchieve normal displayResolve contrastSteroscopic systemsOptical elementsLarge screenComputer vision

The invention discloses a stereoscopic large screen based on a cylindrical lens luminous tube, which comprises a controller and a display screen, wherein a plurality of luminous pixels are arranged on the display screen, and the controller controls the luminous pixels to give out light; and cylindrical lenses are arranged on the luminous pixels, and the image visual difference of left and right eyes is formed according to a cylindrical lens luminous principle. The cylindrical lenses are arranged on the luminous tube or the luminous pixels, the large screen made of luminous points or luminous pixels transmits light of left and right images respectively, the images of the left and right eyes enter the corresponding left and right eyes respectively to form the image visual difference of the left and right eyes according to the cylindrical lens luminous principle, and a final stereoscopic image is formed in a human brain; moreover, during watching, people does not need to wear any stereoscopic glasses, and naked-eye stereoscopic large screen display is realized.

Owner:郑州中原显示技术有限公司

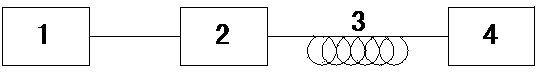

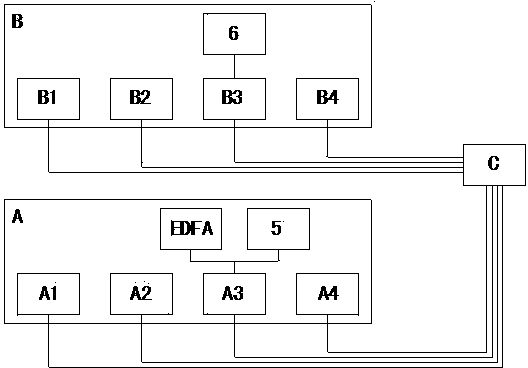

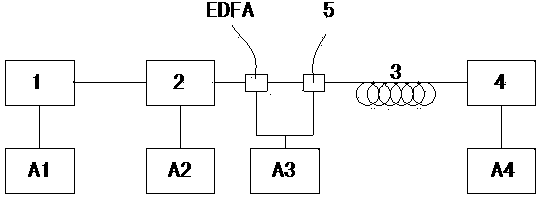

Simulative microwave optical link amplitude and phase regulating and controlling device

ActiveCN103905125AAvoid mutual interferenceIncrease flexibilityElectromagnetic transmissionMicrowaveBand width

A simulative microwave optical link amplitude and phase regulating and controlling device comprises a single microwave optical transmission link, and the microwave optical transmission link is formed by connecting a laser, an outer modulator, a transmission optical fiber and an optical detector in sequence. The simulative microwave optical link amplitude and phase regulating and controlling device is characterized in that the simulative microwave optical link amplitude and phase regulating and controlling device is composed of an amplitude regulating module, a phase regulating module and a control module, wherein the amplitude regulating module and the phase regulating module can independently regulate and control related parameters in an optical domain. The simulative microwave optical link amplitude and phase regulating and controlling device has the advantages that the regulation of the amplitude and the regulation of the phases of a simulative microwave optical link can be carried out independently, mutual interference can be avoided, regulating modes are various, regulation flexibility is large, and regulation accuracy is high; meanwhile, regulation and control measures are all completed in the optical domain, and the problem of limitation of signal bandwidths is solved.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

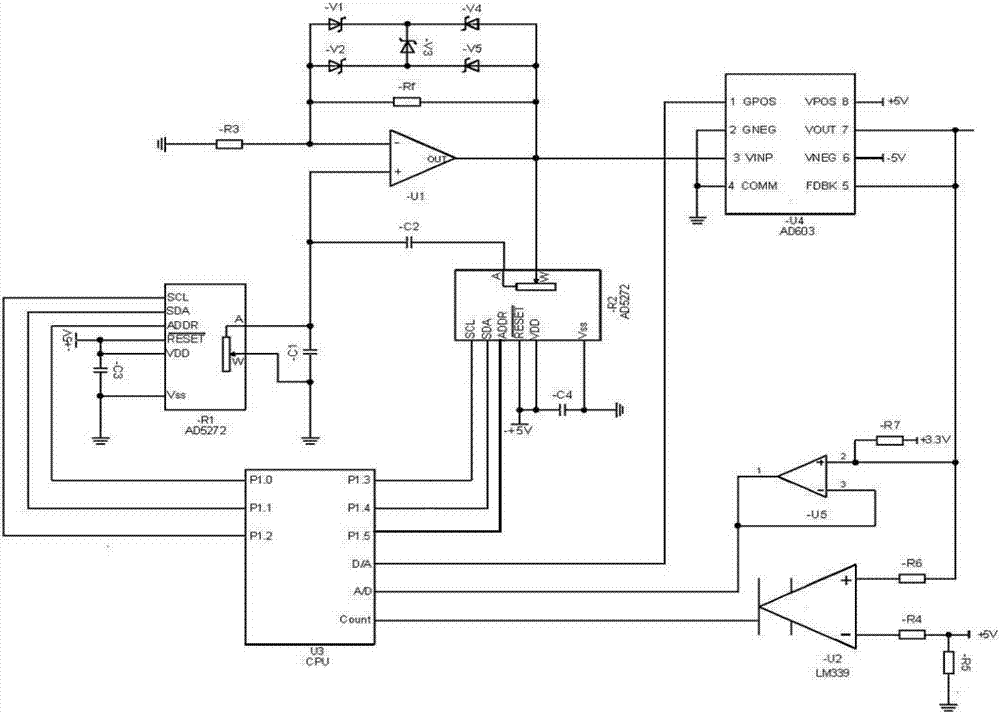

Programmable controlled sine wave generating circuit

PendingCN107276539AResolution frequencyResolution rangeProgramme controlPulse automatic controlHemt circuitsEngineering

The invention discloses a programmable controlled sine wave generating circuit. The circuit comprises a CPU, an oscillation module and a comparator U2; an output end of the oscillation module is inputted into the CPU after being compared by the comparator; and the CPU is used for comparing the frequency of a measured outputted sine wave signal with a set frequency value, and adjusting a first variable resistor R1 and a second variable resistor R2, so that the frequency of the outputted sine wave signal tends to the set value constantly. The programmable controlled sine wave generating circuit provided by the invention can accurately control a high frequency signal generation circuit through the CPU, output a set signal after setting the frequency and amplitude at random, and can detect the frequency and amplitude in a closed-loop way and compare the frequency and amplitude with the set value to perform fine adjustment on an output signal error, so as to generate a sinusoidal signal with accurate and stable frequency and amplitude.

Owner:JIANGSU KAIFAN ELECTRICAL APPLIANCES

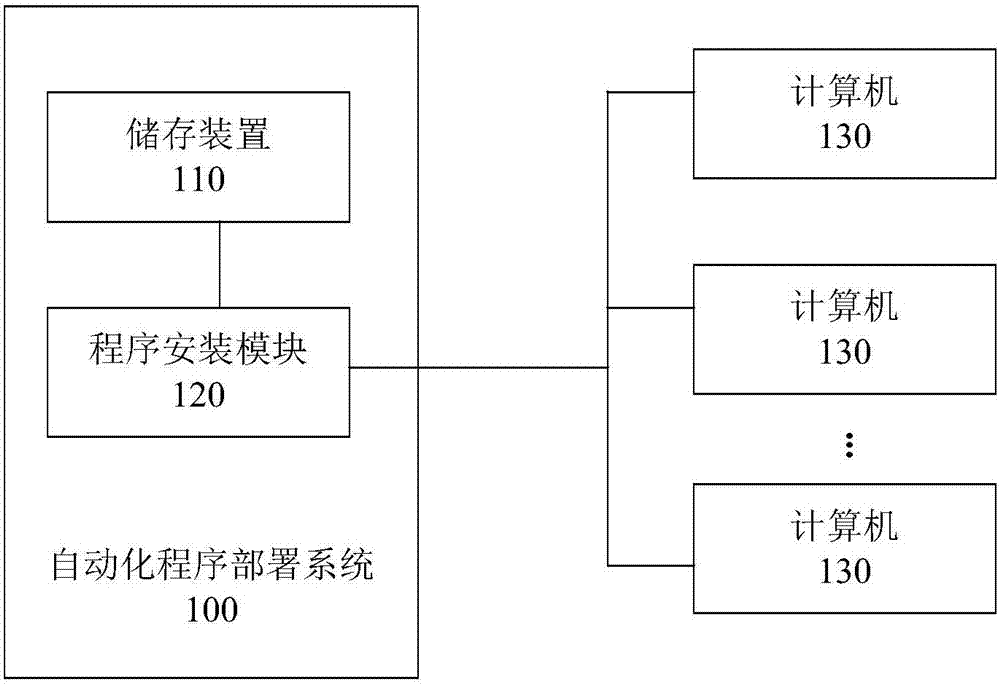

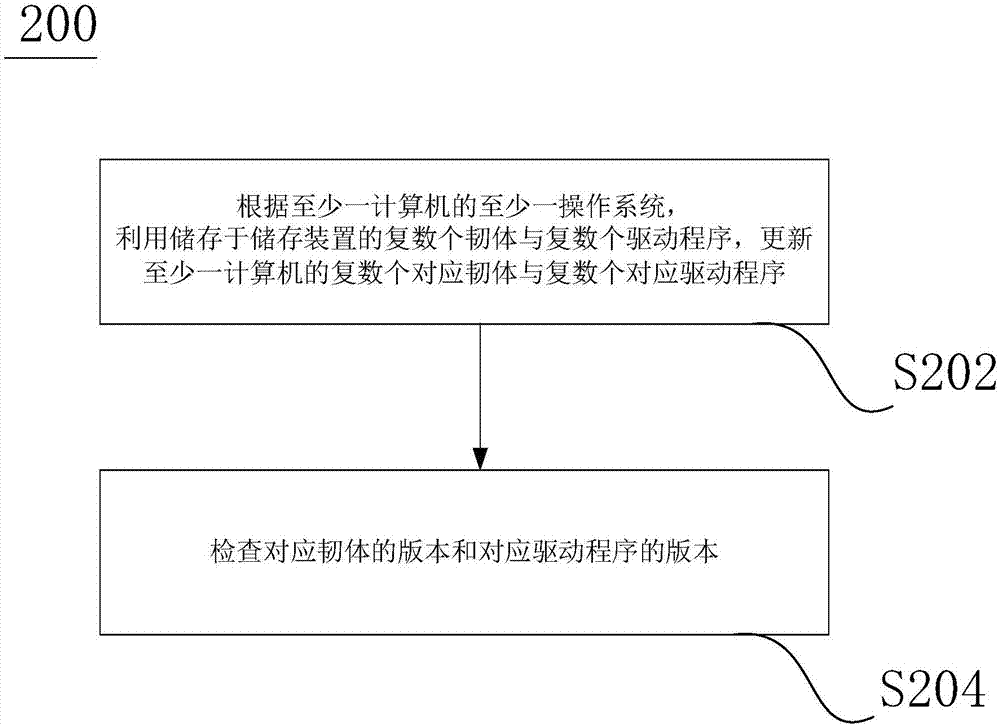

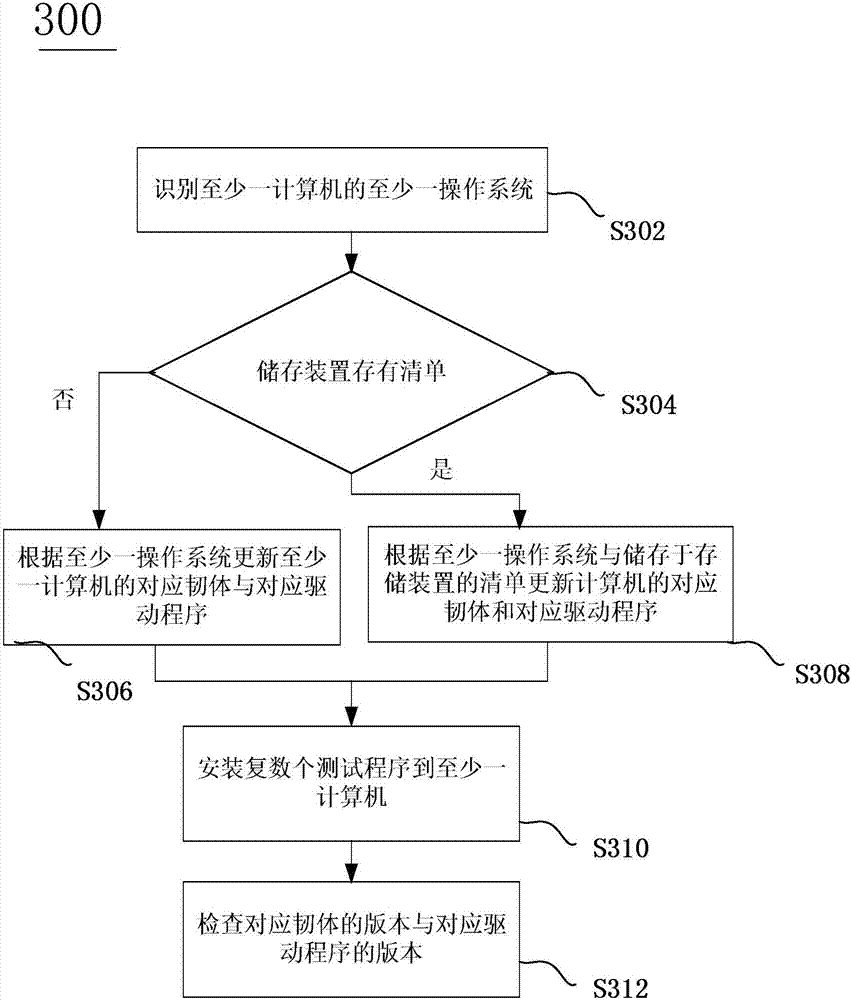

Automatic program deployment system and method for computer test

InactiveCN107977241AImprove deployment efficiencyImprove accuracyProgram loading/initiatingSoftware deploymentComputer moduleTime processing

The invention discloses an automatic program deployment system and method for computer test. The automatic program deployment system includes a storage device and a program installation module; the program installation module is coupled to the storage device; the storage device is used for storing firmware and a drive program; and the program installation module is used for using the firmware andthe drive program to update corresponding firmware and a corresponding drive program of the computer, and checking a version of the corresponding firmware and a version of the corresponding drive program. The number of processed computers is increased during the same time through a complex installation flow of automatic computer program deployment, a check mechanism is provided after installation,and the efficiency of the correctness of computer program deployment are greatly improved.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

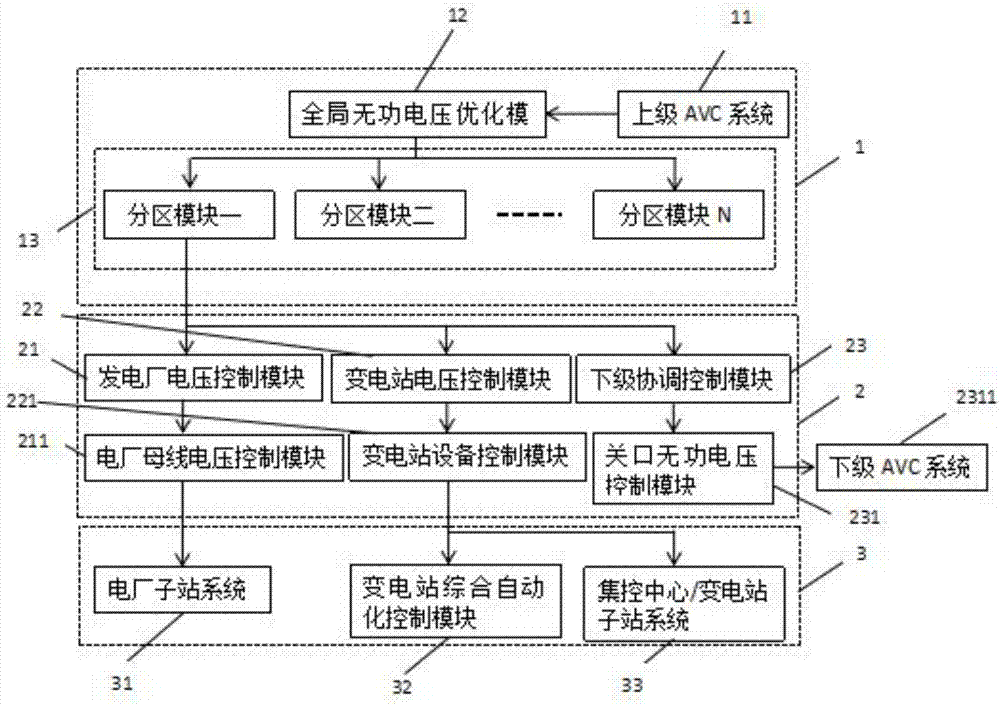

Three-level voltage control system based on soft partitions

InactiveCN107276101AAddressing Adaptive IssuesResolution rangeAc network voltage adjustmentReactive power compensationThree levelControl system

The invention discloses a three-level voltage control system based on soft partitions, and belongs to the technical field of automatic voltage control systems. The three-level voltage control system based on soft partitions includes a tertiary control system, a secondary control system and a primary control system, the tertiary control system is connected with the secondary control system and controls the secondary control system, and the secondary control system is connected with the primary control system and controls the primary control system. The three-level voltage control system based on soft partitions solves the problem that division of an existing three-level voltage control mode control region is solidified in a hardware controller in the form of parameters, and continuous development of an electric power system and substantial change of a real-time operation condition are difficult to adapt to; and the three-level voltage control system based on soft partitioning has a stable and reliable power supply system, a long service life, high practicability, and a good using effect, and thus is convenient for popularization and use.

Owner:林浩博

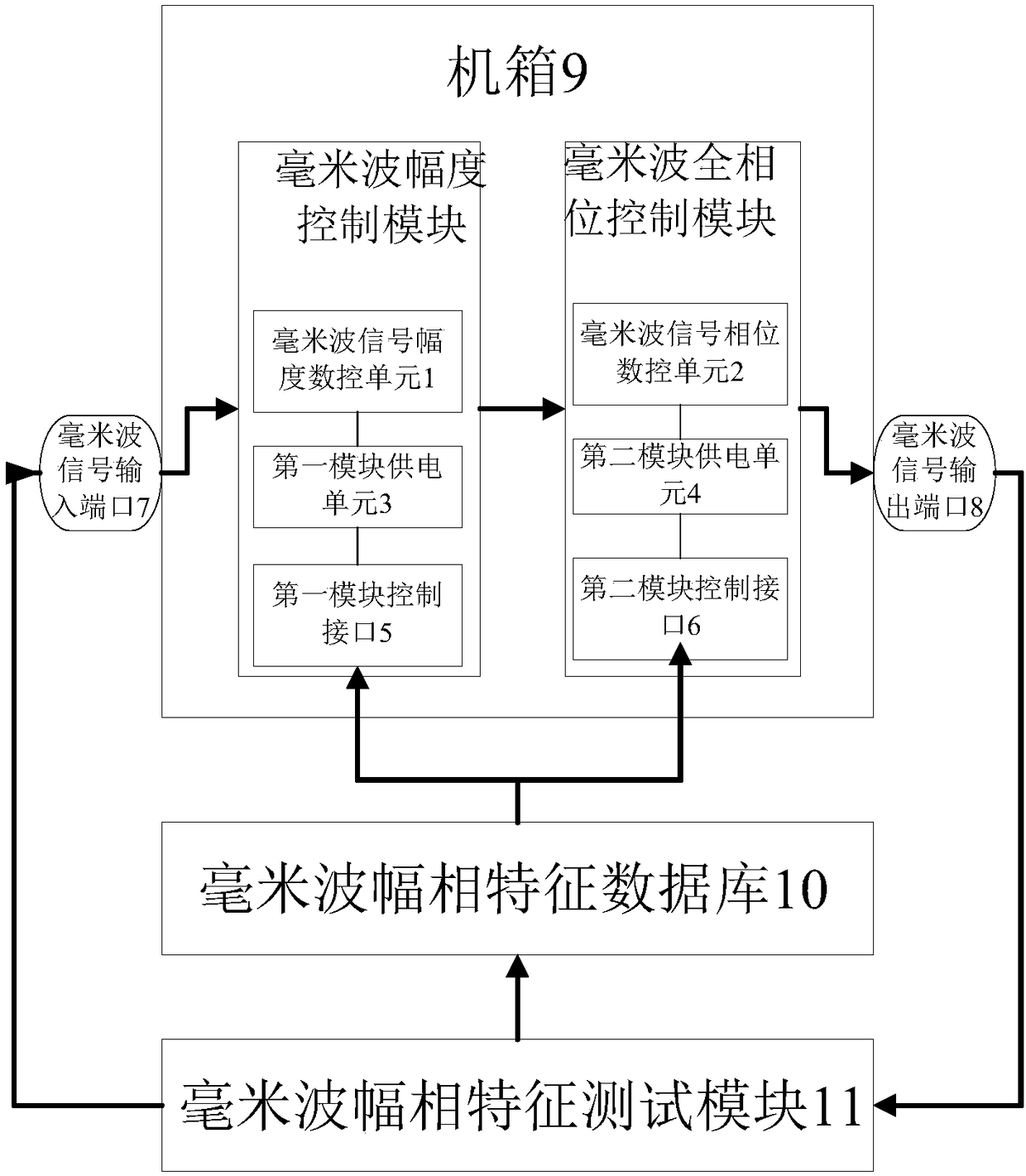

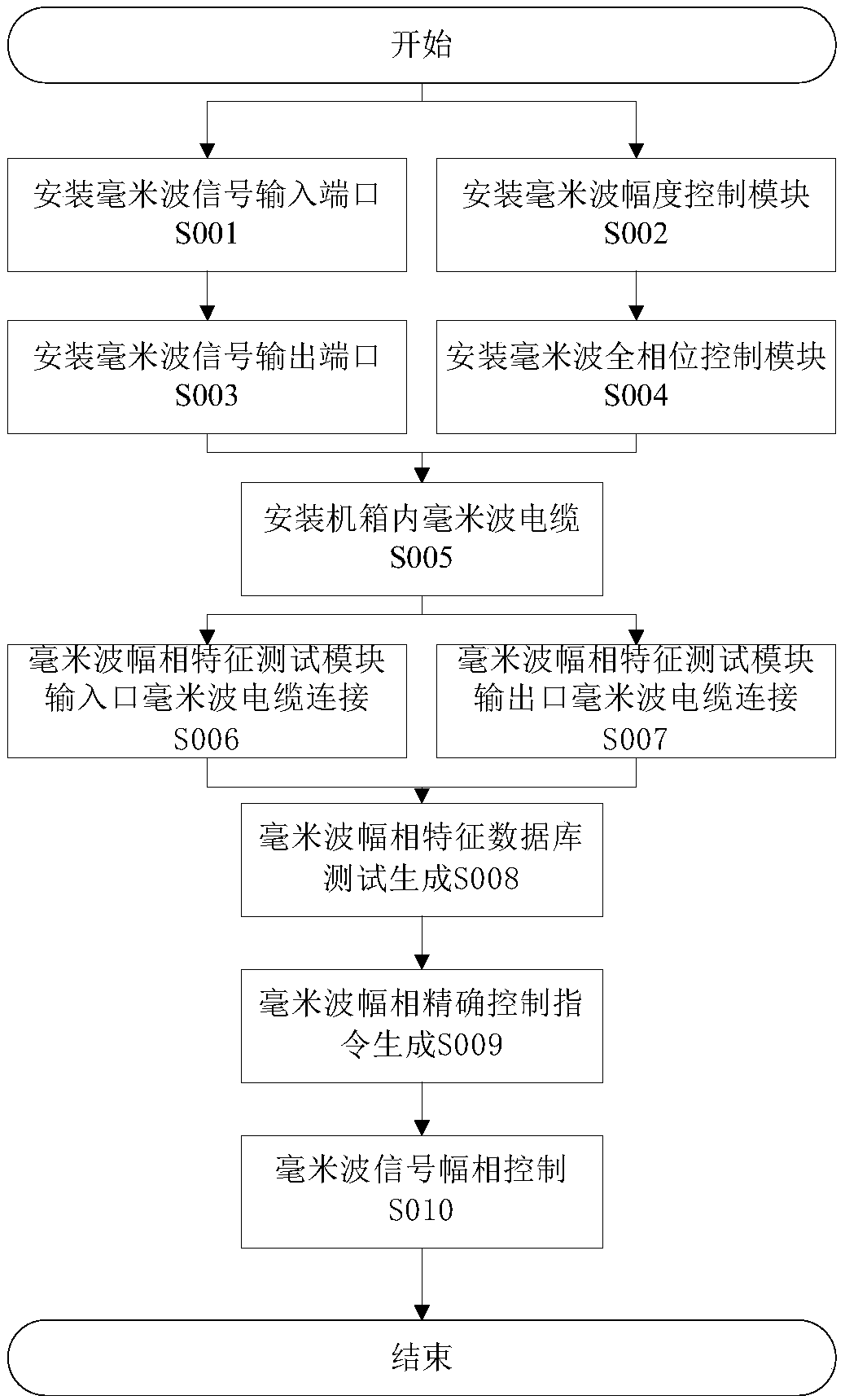

Precise millimeter-wave amplitude phase control system and method

InactiveCN108319157ASolve the technical problem of poor control accuracyResolution rangeSimulator controlA wave amplitudeControl system

The invention provides a precise millimeter-wave amplitude phase control system and method. The system is composed of a millimeter-wave amplitude control module, a millimeter-wave full-phase control module, a millimeter-wave amplitude phase characteristic test module, a millimeter-wave amplitude phase characteristic database and a case. The millimeter-wave amplitude control module and the millimeter-wave full-phase control module are installed and fixed successively according to a millimeter wave signal transmission direction so as to realize power amplitude control and full-phase control of the millimeter wave signal; and signal input ports of the millimeter-wave amplitude control module and the millimeter-wave full-phase control module are connected with at least one millimeter-wave signal input port formed in the end surface of the case. Therefore, a technical problem of crossed coupling of the amplitude and phase of the millimeter-wave signal is solved; and accurate control of theamplitude phase of the millimeter-wave signal is ensured.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

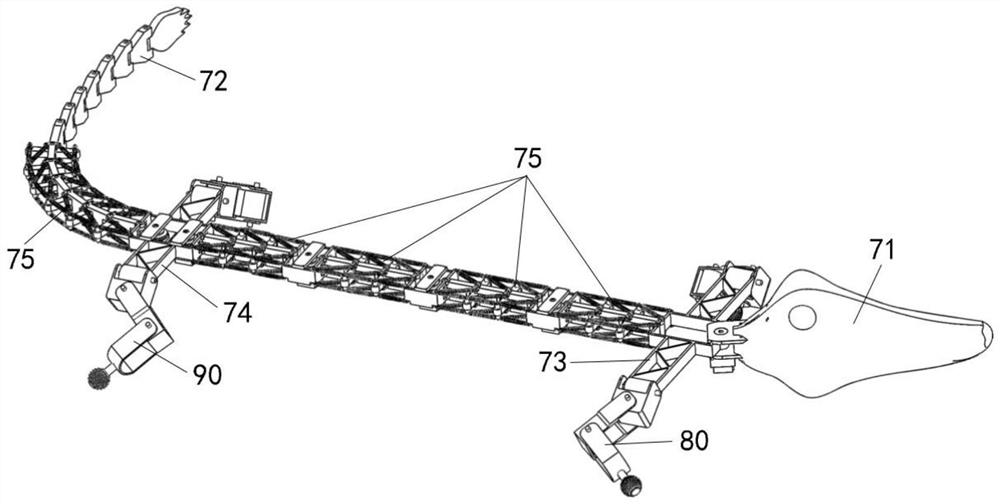

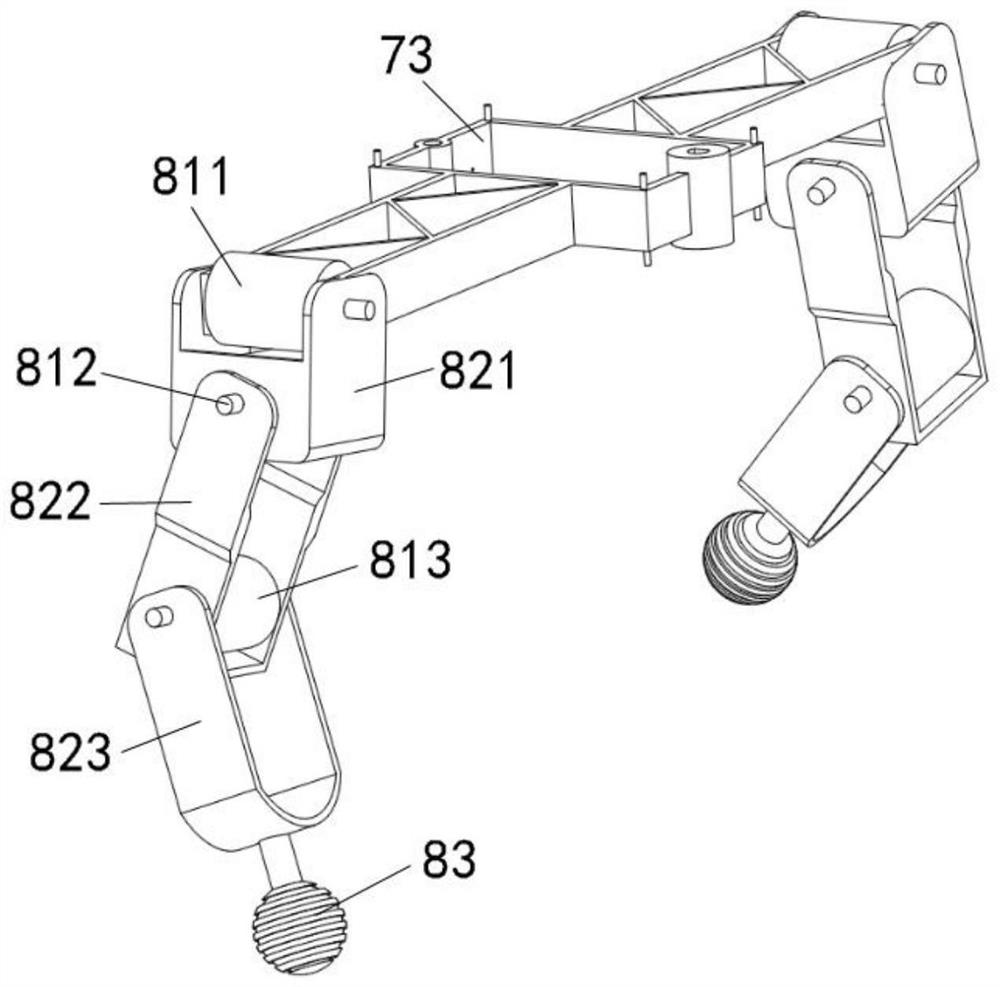

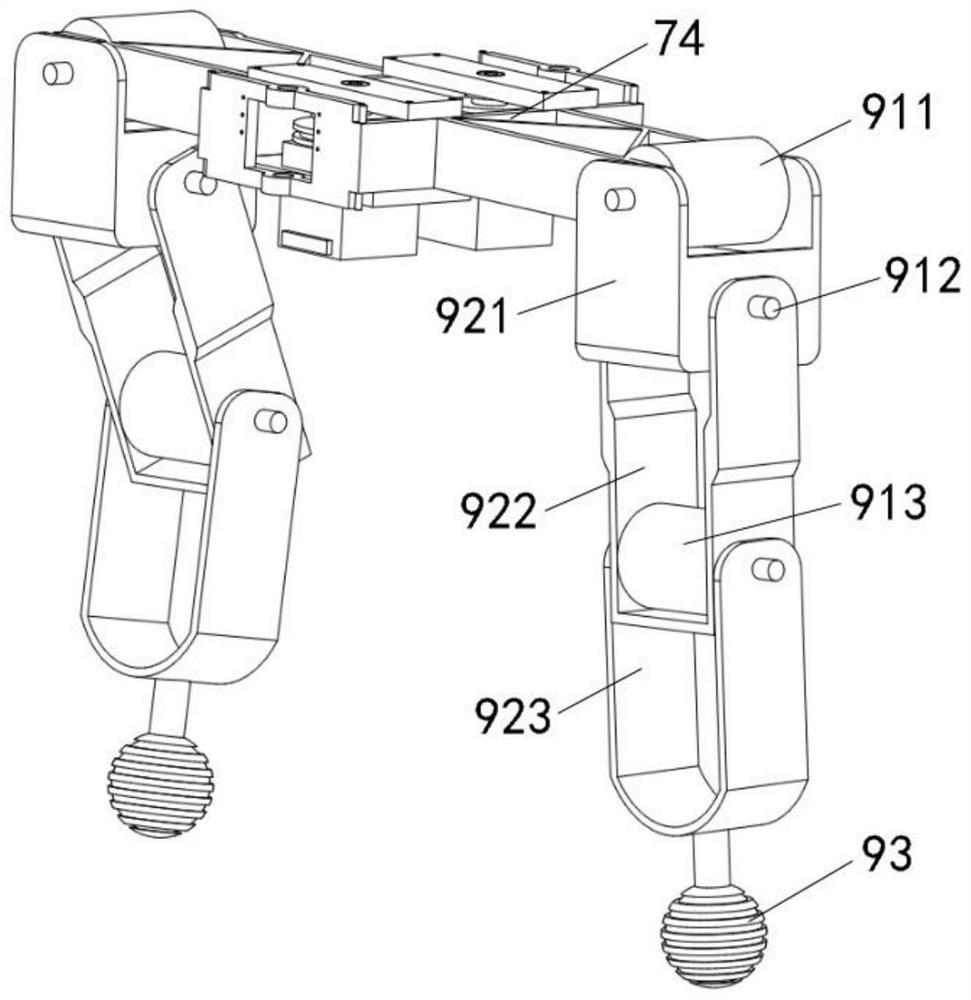

Crocodile-imitating robot

ActiveCN113650026AResolution rangeResolution frequencyArmsPhysical medicine and rehabilitationAlligator

The invention discloses a crocodile-imitating robot. The crocodile-imitating robot comprises a head, a tail, a front trunk, a rear trunk and a plurality of rope-driven swing units, wherein the head is movably connected to the front trunk; the tail is movably connected to the rear trunk; two movable front legs are arranged on the front trunk; two movable rear legs are arranged on the rear trunk; and the rope-driven swing units are movably connected between the front trunk and the rear trunk in sequence. According to the scheme, the rope-driven swing units can be used for swinging in a flexible driving mode, that is, rigid driving is replaced by rope driving, the swing effect is more natural and real, large-amplitude high-frequency swing can be achieved, and therefore the problem that rigid driving is difficult to adapt to large-amplitude and high-frequency swing postures is practically solved.

Owner:SUN YAT SEN UNIV

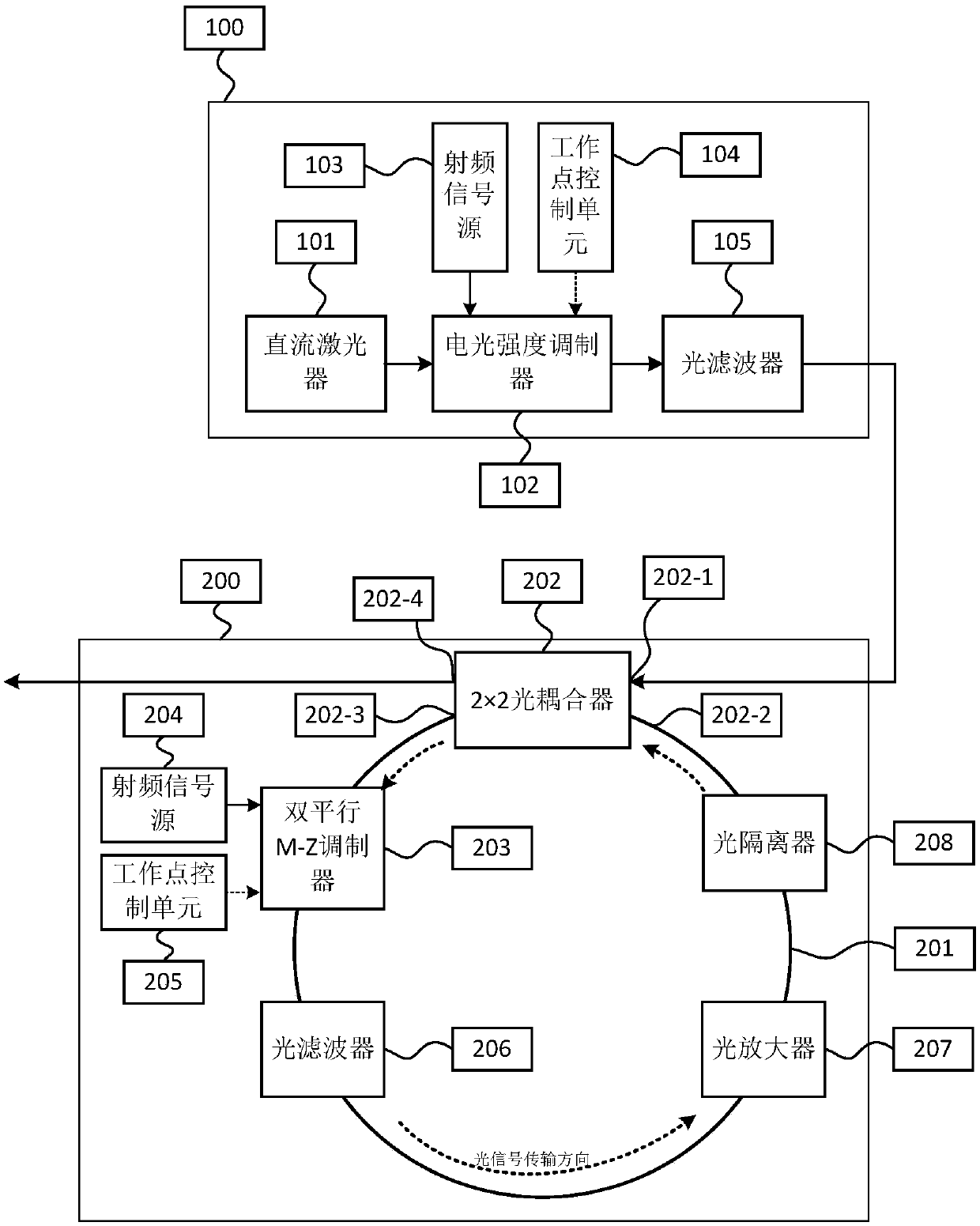

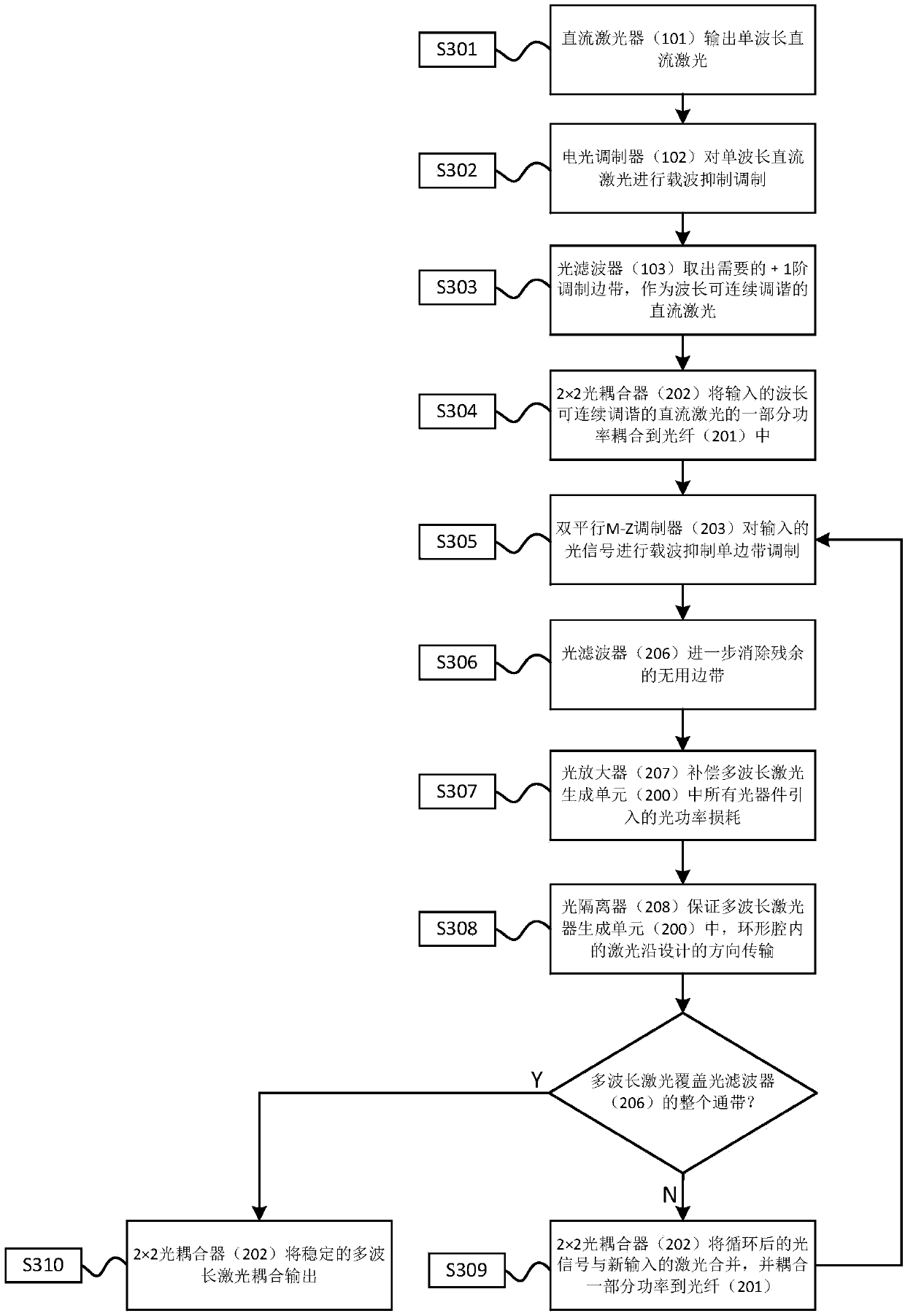

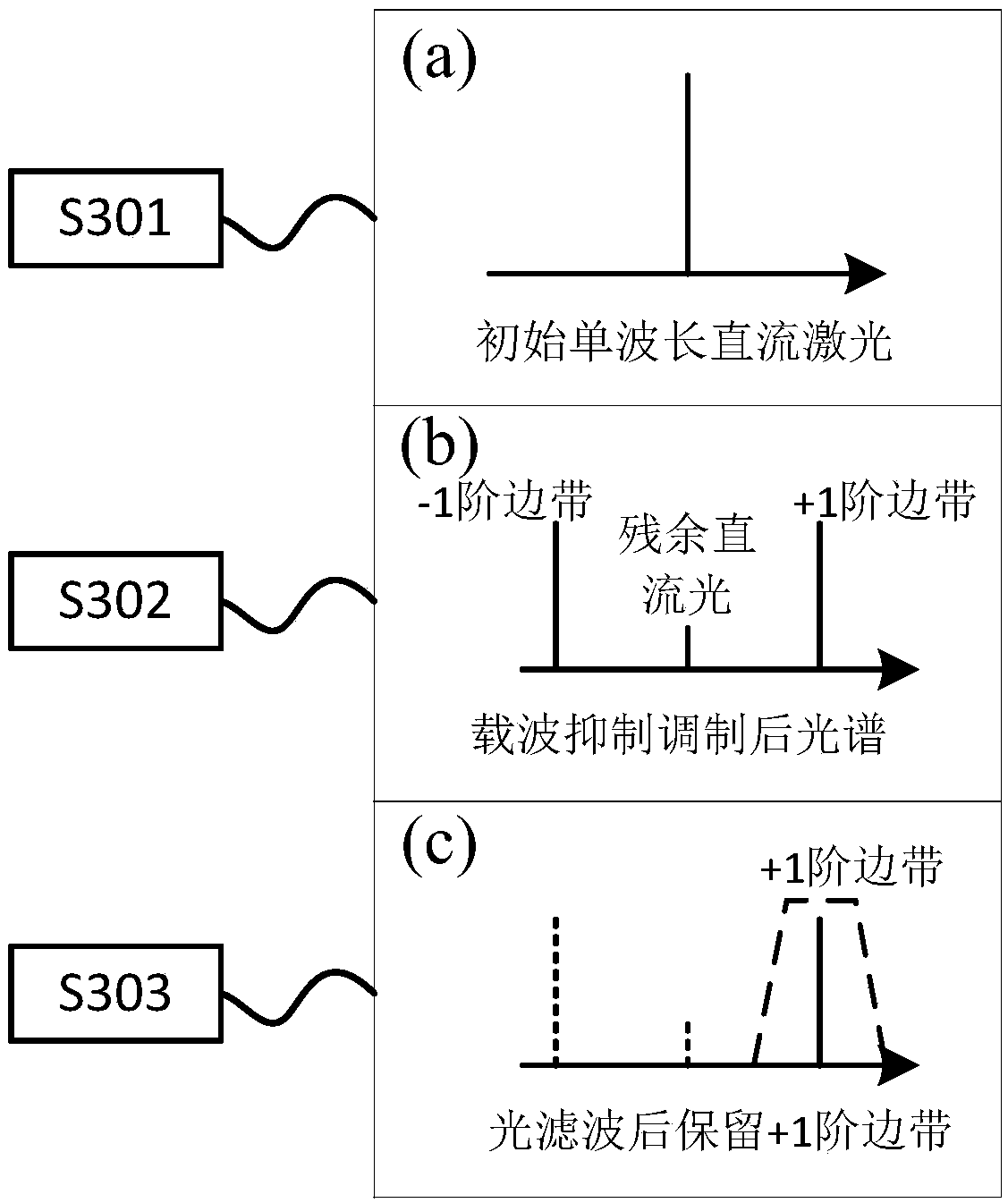

Wavelength-tunable multi-wavelength laser production system and method

InactiveCN109617617AMeet application needsBroaden the field of technologyElectromagnetic transmittersOptical communicationOptical coupler

The invention discloses a wavelength-tunable multi-wavelength laser production system. The system comprises a tunable DC laser production unit and a multi-wavelength laser production unit; the tunableDC laser production unit comprises a DC laser, a first electro-optical modulator, a first radio frequency signal source, a first work point control unit and a first optical filter; the multi-wavelength laser production unit comprises an optical coupler, a second electro-optical modulator, a second radio frequency signal source, a second work point control unit, a second optical filter, an opticalamplifier and an optical isolator. The multi-wavelength laser production system has the characteristic that the initial wavelength and the beam interval are flexible and continuously tunable. The problem that the conventional cascaded modulator is large in multi-wavelength amplitude difference, complex in control logic and high in signal insertion loss is solved through cyclic frequency shift andinner-ring gain compensation, and the system has application values in the wavelength multiplexing optical communication, optical channel technology, and microwave photon radar technology and like fields.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

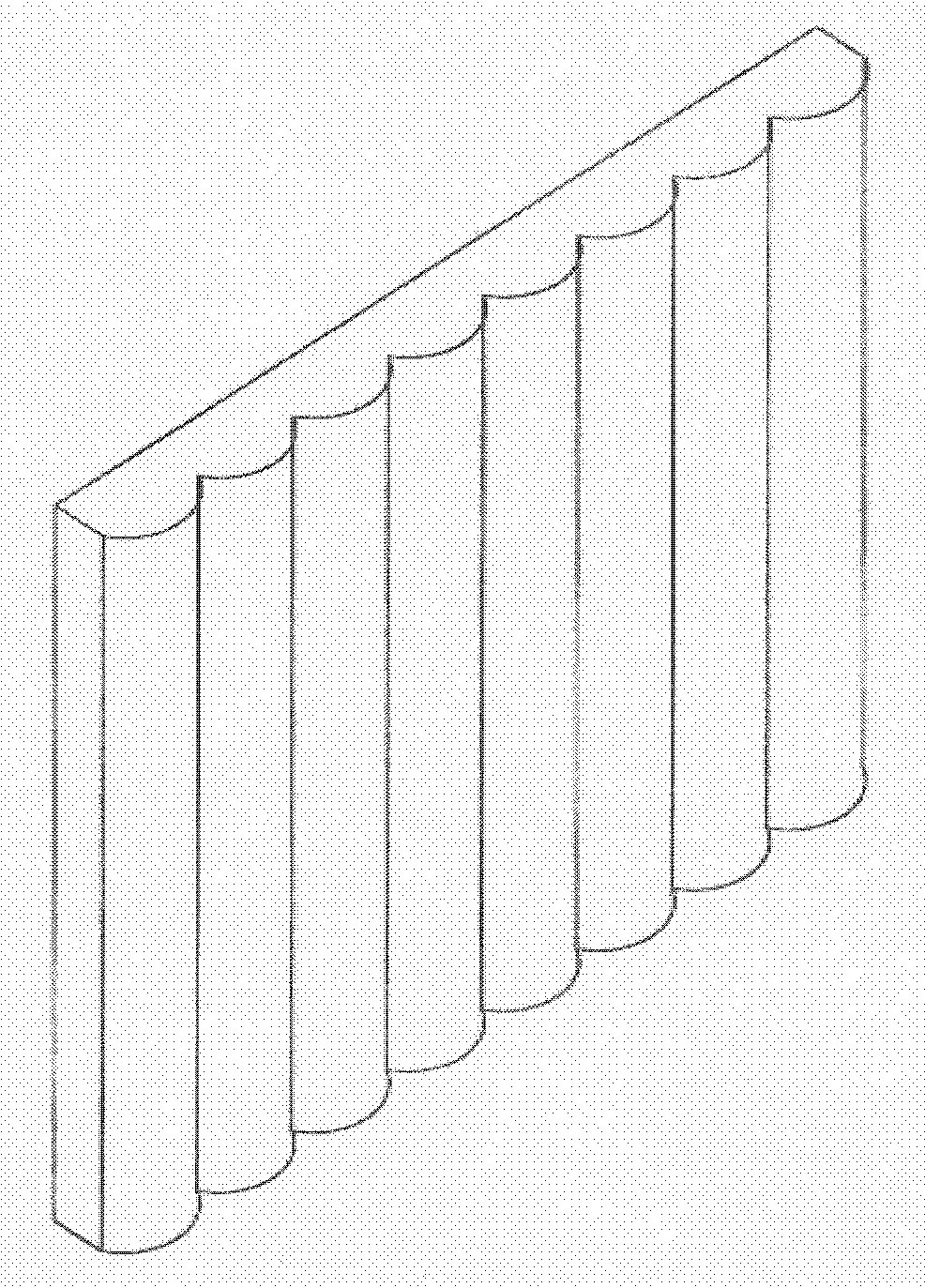

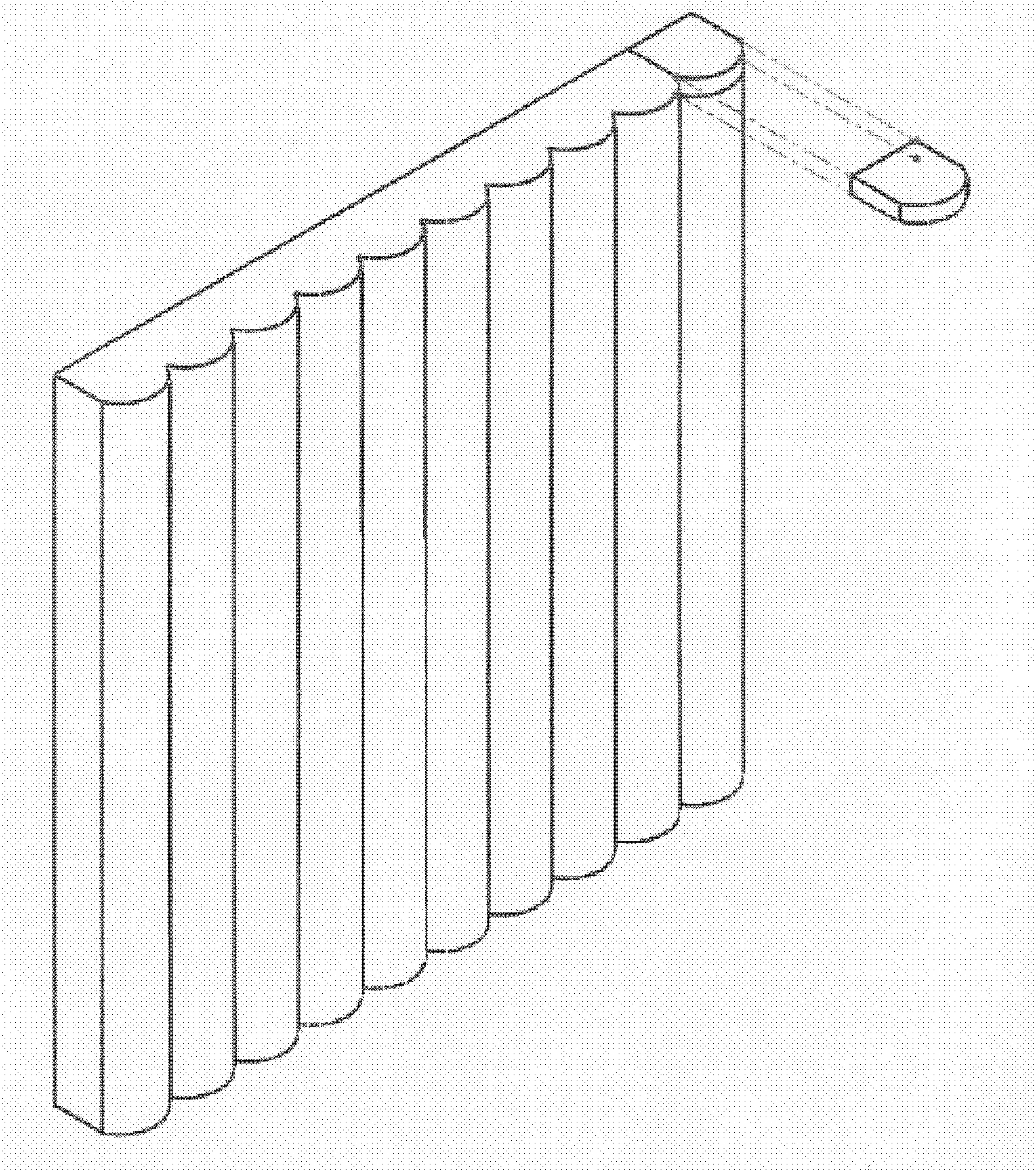

Modular furniture processing method

InactiveCN107877657AImprove structural performanceResolution rangeOther plywood/veneer working apparatusWood veneer joiningSolid woodEngineering

The invention discloses a modular furniture processing method. The method comprises the following steps of (1) preparing materials; (2) pre-modeling, specifically, designing a furniture model in advance, measuring the thickness of the furniture model and selecting a plurality of wood sheets with uniform thickness, wherein the total thickness of the multiple wood sheets is equal to the actual required thickness of the furniture model; (3) carrying out sawing in a staggered mode, specifically, sawing the wood sheets in advance according to parts required to be curved and staggered according to the curved shape of the furniture model; (4) carrying out gluing, specifically, the mutual contact surfaces between the wood sheets are brushed with glue; (5), carrying out hot -pressing; (6) carryingout polishing; and (7) carrying out paint spraying, specifically, furniture is sprayed with paint, and the paint surface is dried. The method has the advantages of being convenient to manufacture, attractive in appearance, free of breakage, cracking or deformation and capable of meeting the natural and environment-friendly requirements of solid wood furniture, in addition, the mechanical batch production can be facilitated, the production efficiency is high, the material loss is extremely small, the cost can be greatly lowered, and the product quality is stable.

Owner:CHENGDU JINCHUANTIAN AGRI MACHINE MFG

Adjustable high temperature condensate water circulating and recovering system and recovering method

InactiveCN1654830ASmooth recyclingGood siphon effectSteam/vapor condensersMachines/enginesRecovery methodSiphon

This invention relates to a high temperature condensed water recycling system and its recycling method, which comprises the following steps: connecting the siphon down mouth of the water circle with water storing tar; connecting the upper mouth of the siphon pipe through connection pipes with the storing tar; connecting the recycle pressure loading pipe with one pass of the three-way valve through recycling pipe; connecting the other two passes of the valve with the high pressure water pump through the three-pass valve; connecting the third pass with water storing tar; connecting one pass of three-pass auxiliary boost with storing tar and the second one with water pump with high pressure and third one with the three-pass valve through connection pipe and valve.

Owner:杭州鸿德节能设备有限公司

Preparation method of tsamba

InactiveCN108740746AEvenly heatedTo solve the large limitations of the preparationFood ingredient as mouthfeel improving agentPlanting seedDigestion

The invention relates to the field of food manufacturing, in particular to a preparation method of tsamba. The preparation method comprises the following steps of firstly, screening the highland barley of to-be-prepared tsamba, and removing the wild plant seeds, stones and soil blocks; cleaning, soaking the screened highland barley into water to clean, removing the empty grains, airing, and flatlylaying the cleaned highland barley onto ground to be aired; washing by hot water, putting the aired highland barley into hot water, and washing; after washing is finished, draining water, putting into a storage bag, sealing, perfoming stir-frying again, fetching out the highland barley in the storage bag, putting into a frying pot, and adding sands to stir-fry the highland barley; finally, grinding the fried highland barley, so as to prepare the tsamba. The preparation method has the advantages that the problems of the existing tsamba preparation method that the large limitation exists in thepreparation process; although the purpose of aging the highland barley is reached by expanding, the amylopectin of the highland barley is crushed in the puffing process; although the storage time ofthe highland barley is prolonged, the content of nutrients and the digestion rate are greatly decreased.

Owner:日喀则市昂仁县朵堆康萨农产品发展有限公司

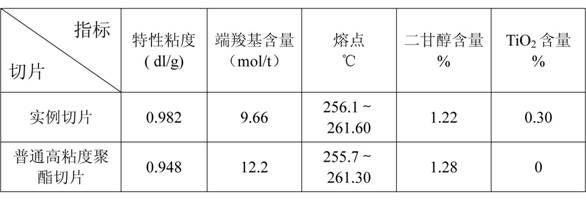

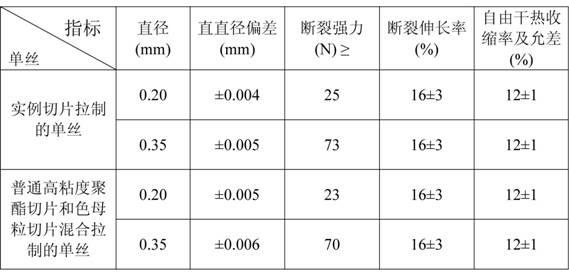

Preparation method of functional high-viscosity slice for monofilaments

InactiveCN101935394AImprove functionalityHigh strengthMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterDiol

The invention discloses a preparation method of a functional high-viscosity slice for monofilaments. The functional high-viscosity slice is prepared by using diacid and diols as raw materials, producing a functional low-viscosity polyester slice with the intrinsiclimiting viscosity not more than 0.70 dl / g by utilizing a PTA (Purified Terephthalic AcidPreferential Trade Agreement) method and producing a functional high-viscosity slice with the intrinsiclimiting viscosity ranging from 0.76 dl / g to 1.2 dl / g for monofilaments through continuous solid-phase polycondensation. The functional high-viscosity slice for the monofilaments, which is produced by using the method, has stable performance, excellent quality and stable color additive content adjustable in a certain range. The slice can be directly used for stretching and controlling monofilaments, without adding a color-adjusting master batch slice. The invention is also convenient to control a downstream user production process, improve the stability of monofilament production and decrease the generation of scraps so as to decrease the production cost of downstream users.

Owner:GUANGDONG HUATIE TONGDA HIGH SPEED RAILWAY EQUIP CORP

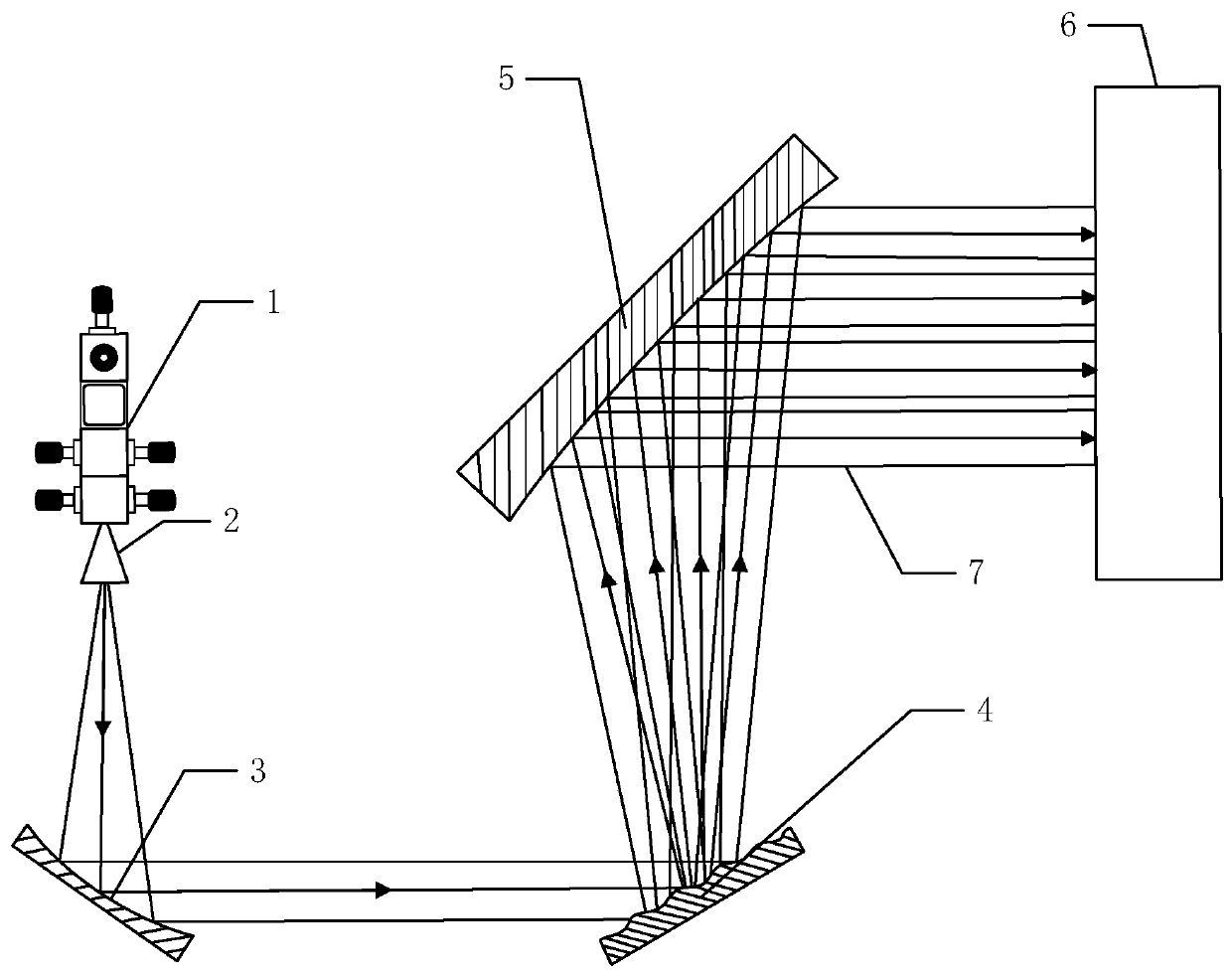

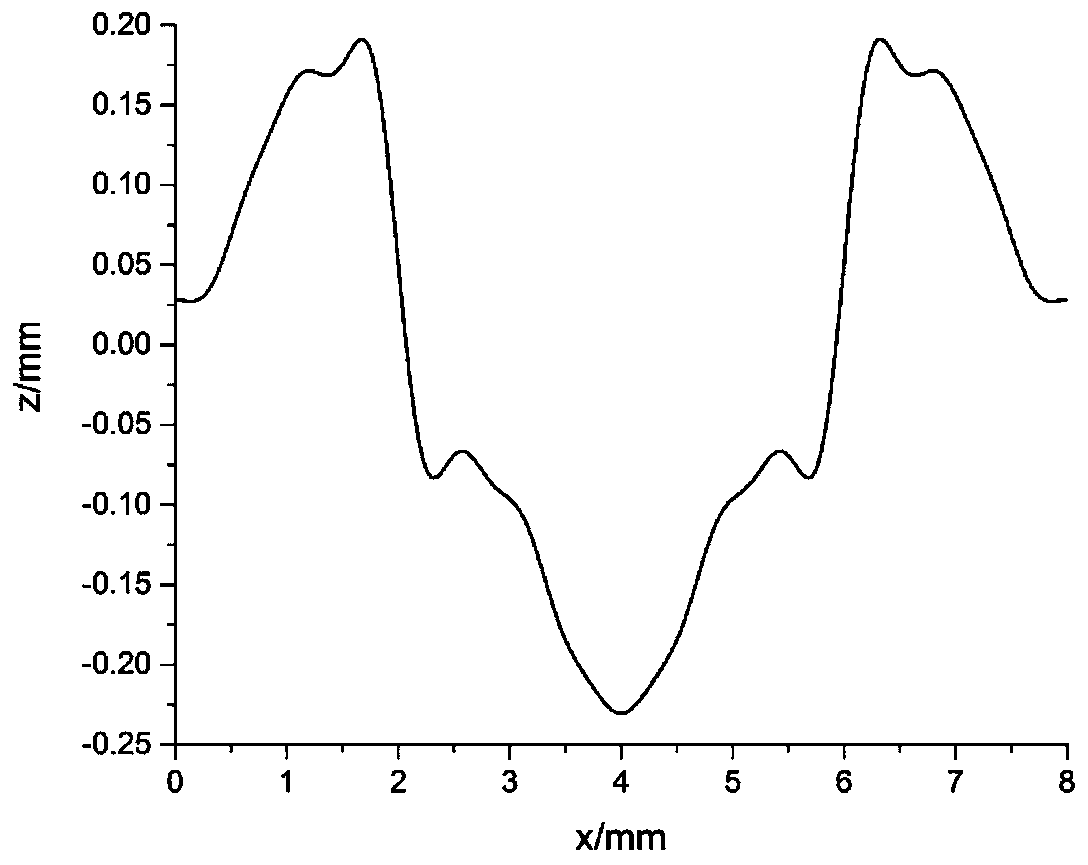

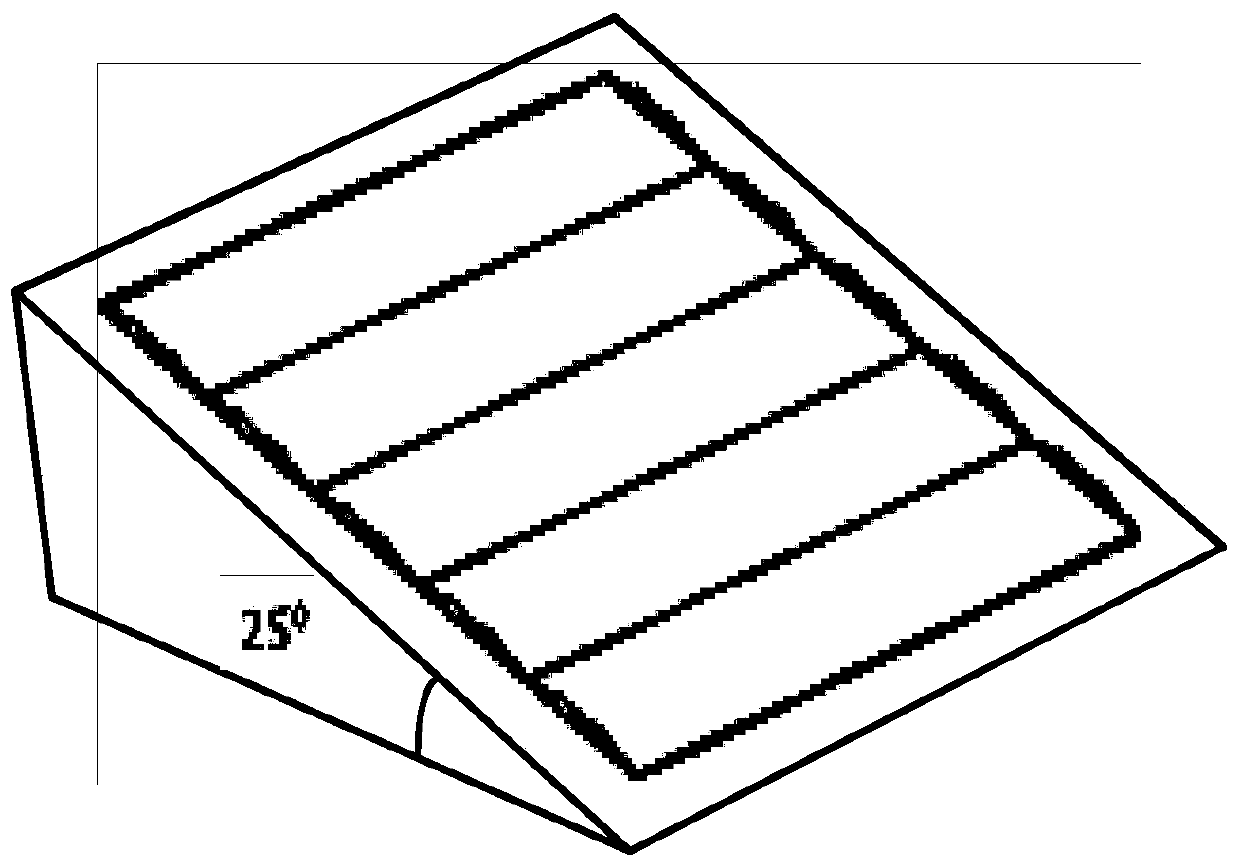

Terahertz wave beam splitting system

ActiveCN111024642ASimple structureEasy to processOptical detectionMaterial analysis by optical meansGaussian beamBeam splitting

The invention discloses a terahertz wave beam splitting system. The device comprises a frequency source frequency multiplier module, a Gaussian beam shaping horn antenna, a one-dimensional Fourier phase grating, a thermoelectric detector and two 90-degree offset parabolic mirrors, the output end of the frequency source frequency multiplier module is electrically connected with the input end of a Gaussian beam shaping horn antenna; an output signal is coupled to a free space through a Gaussian beam shaping horn antenna; the beam waist position of an output signal coincides with the focus of the90-degree offset parabolic mirror A, the output signal is sent to the surface of the one-dimensional Fourier phase grating through collimation of the 90-degree offset parabolic mirror A and is bunched through the 90-degree offset parabolic mirror B, and the thermoelectric detector can scan and receive the bunched signal. The terahertz wave beam splitting system can avoid using a plurality of terahertz frequency sources, reduces the complexity of a terahertz array receiver, and is simple in structure, convenient to process, low in cost and high in diffraction efficiency.

Owner:SOUTHEAST UNIV

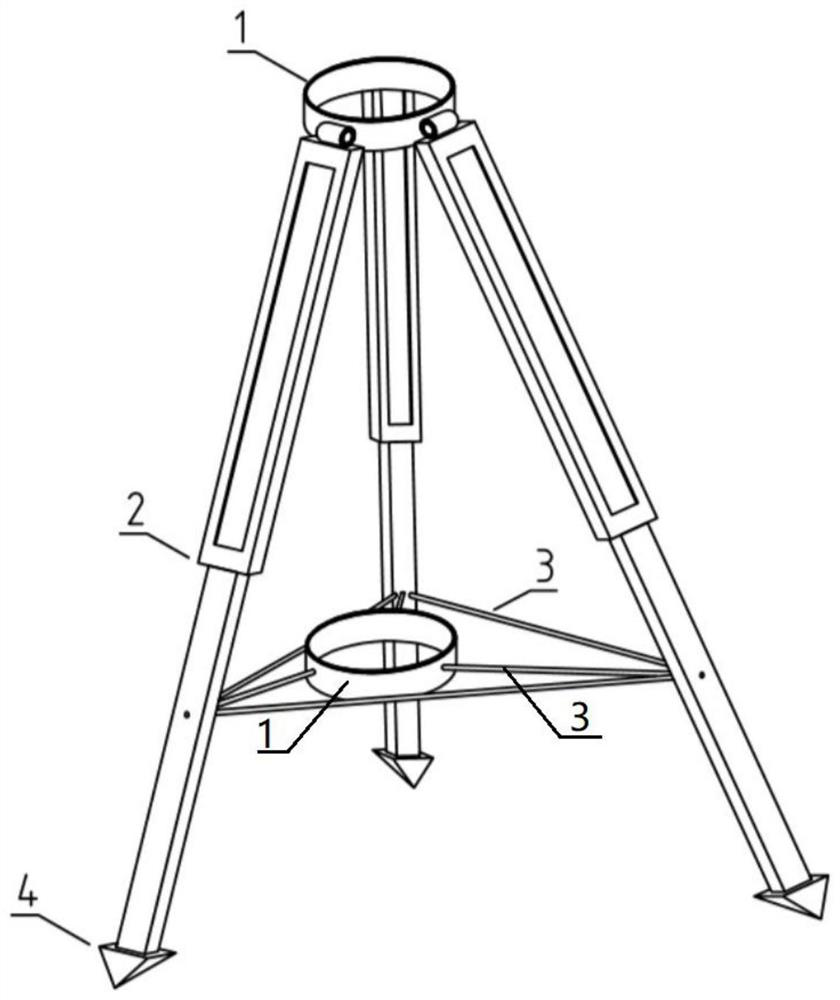

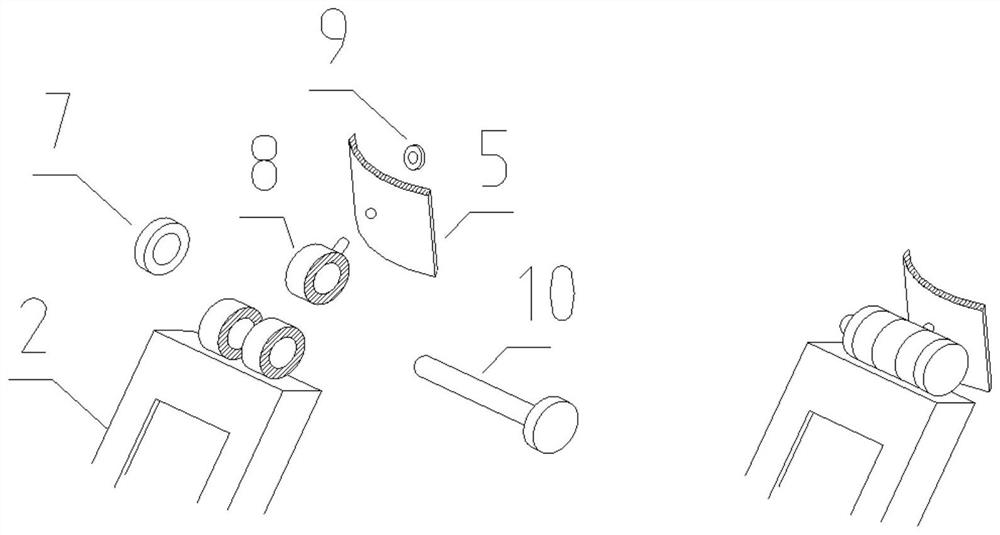

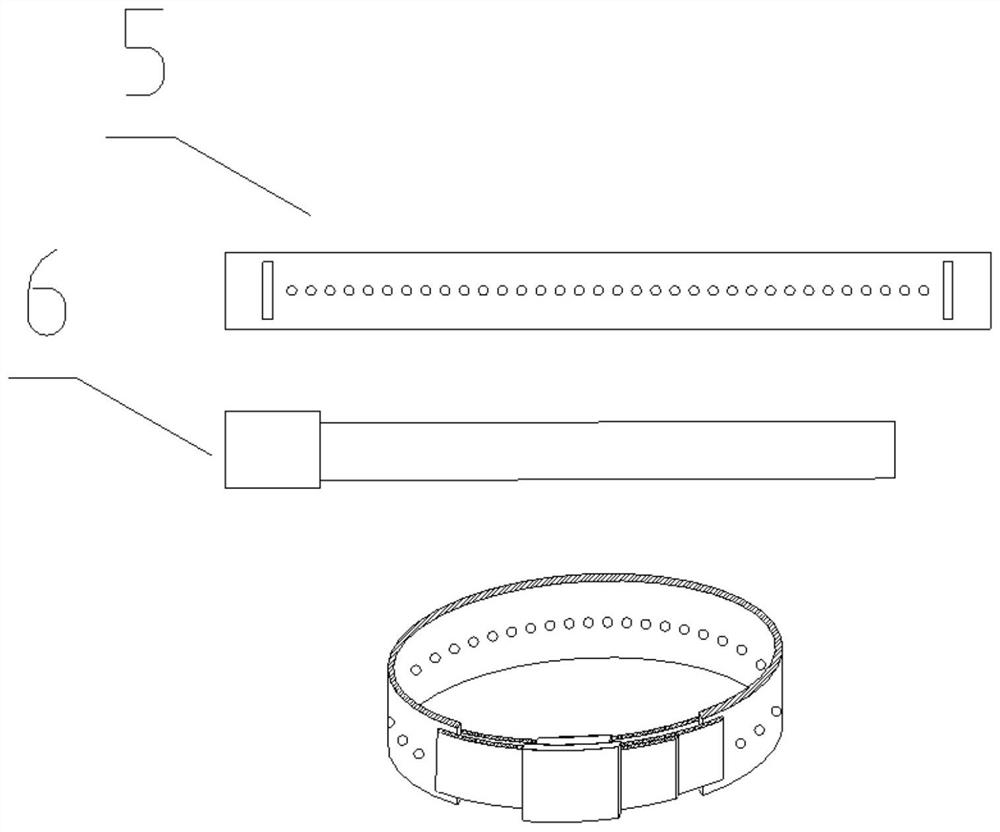

Stereotyped seedling fixing device and method

ActiveCN111631078ACause damageSolve the adjustmentCultivating equipmentsChinese charactersAgricultural engineering

The invention discloses a stereotyped seedling fixing device and method. The fixing device includes fixing rings, foot frames, telescoping casing pipes, foot supports, etc. The method includes puttingseedlings in soil pits to perform backfilling, determining support height, winding a flexible material, and passing a belt through an upper fixing loop to tighten to form the fixing rings; connectingconnection blocks and the upper fixing loop at a connection position through reserved round holes and a second nut; performing equidistant arrangement from the first reserved round hole according tothe number of the foot frames; connecting a buckle shaped like a Chinese character 'jing' and a lower fixing loop through the second nut, performing equidistant arrangement from the first reserved round hole, fixedly connecting the lower parts of the foot frames and the buckle shaped like a Chinese character 'jing' through the telescoping casing pipes, the second nut and the buckle shaped like a Chinese character 'jing', determining the lengths of the casing pipe, and tightly screwing, rotating and fixing a screw; and passing rivets through the reserved holes of the foot supports, and beatingthe foot supports into soil layers or other structural layers to form the device. Thus, the technical problems that seedling fixing supports are inconvenient in assembling and disassembling, unstablein seedling supporting and not suitable for irregular terrain can be solved.

Owner:CHINA FIRST METALLURGICAL GROUP

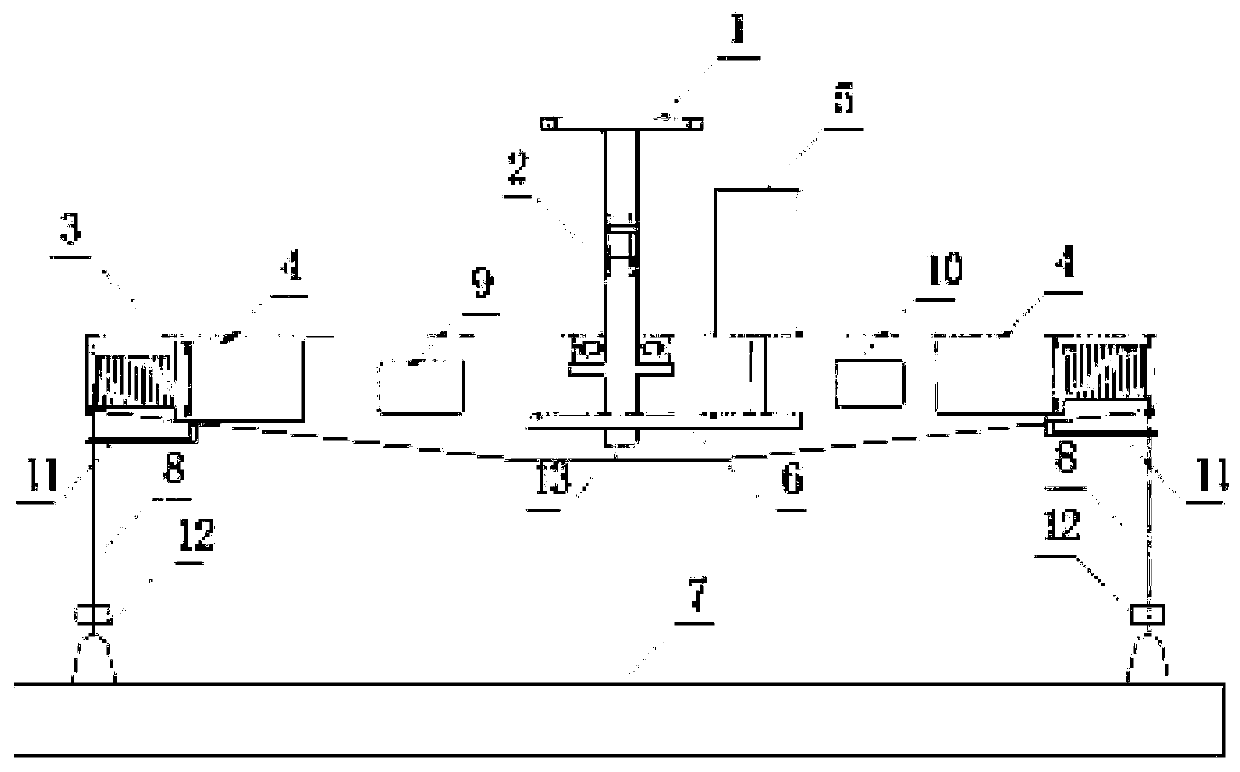

Multi-suspension-point liftable rotating equipment

PendingCN110065881ARealize landing shutdown protectionSolve leveling problemsLoad-engaging elementsGear wheelEngineering

The invention relates to the technical field of hoisting machinery, in particular to multi-suspension-point liftable rotating equipment. The structure of the equipment is characterized in that a fixing device is connected with a rotating beam, lifting winches are embedded in the two ends of the rotating beam, and a rotating speed reducing motor is attached to the upper part of the rotating beam. The rotating speed reducing motor is in gear meshing with the fixing device to realize rotation of the rotating beam and a lifted object. Meanwhile, the structure is equipped with an overload and landing protection system, so that the safety and practicability of the structure in applications are ensured. Through optimal design, the structure is light, and large space and heavy structures are not required for cooperation, and the functions of lifting rotation, assembly alignment and the like in more scenes are realized.

Owner:沈阳野果广告有限公司

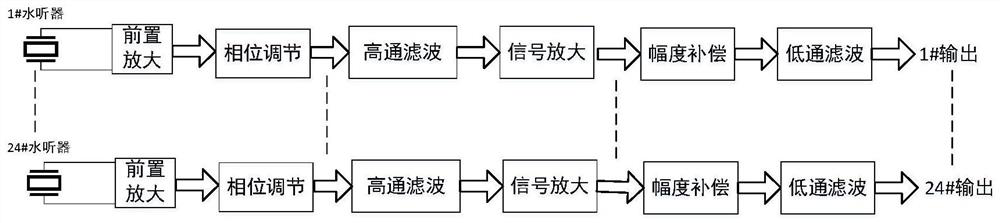

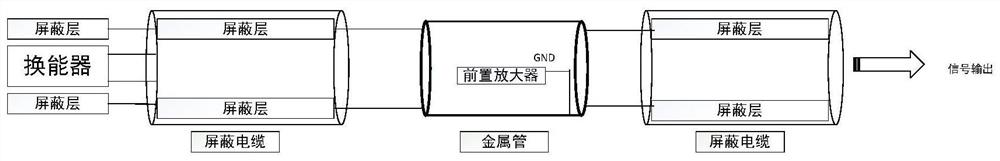

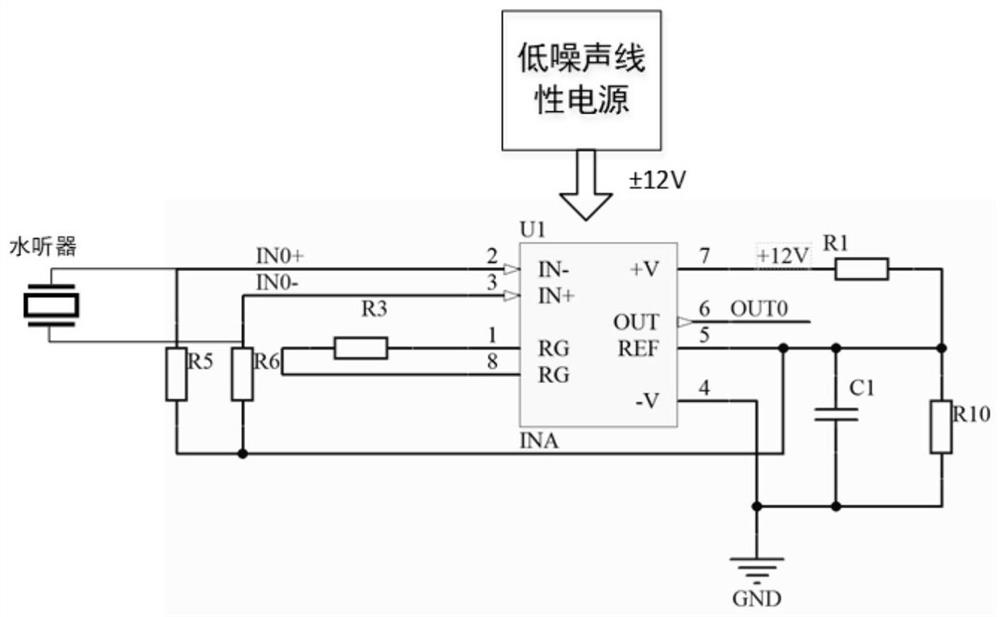

Multi-channel sonar buoy signal preprocessing system and method

ActiveCN112383863AResolution rangeFix stability issuesFrequency response correctionCapacitanceBroadbanding

The invention discloses a multi-channel sonar buoy signal preprocessing system and method, and the system comprises a plurality of channels, and each channel comprises a hydrophone, a shielding cable,a pre-amplification circuit, a phase adjustment circuit, a high-pass filter circuit, a signal amplification circuit, an amplitude adjustment circuit, and a low-pass filter circuit. On the basis of designing the low-noise pre-amplification circuit, the integrated grounding shielding technology is adopted to effectively reduce the broadband noise interference of preprocessing. High-precision resistors and capacitors are used for adjusting the consistency of multiple channels, and the stability degree of the high consistency of the multiple channels is ensured through the reliability of the resistor-capacitor device. According to the invention, while low-noise preprocessing is realized, the stability problem of multichannel amplitude and phase consistency difference is solved, and the multichannel preprocessing performance of sonar is further improved; and meanwhile, the structure is simple, hardware implementation is easy, high practicability is achieved, and application and popularization are convenient.

Owner:西安瑞祥深海科技有限公司

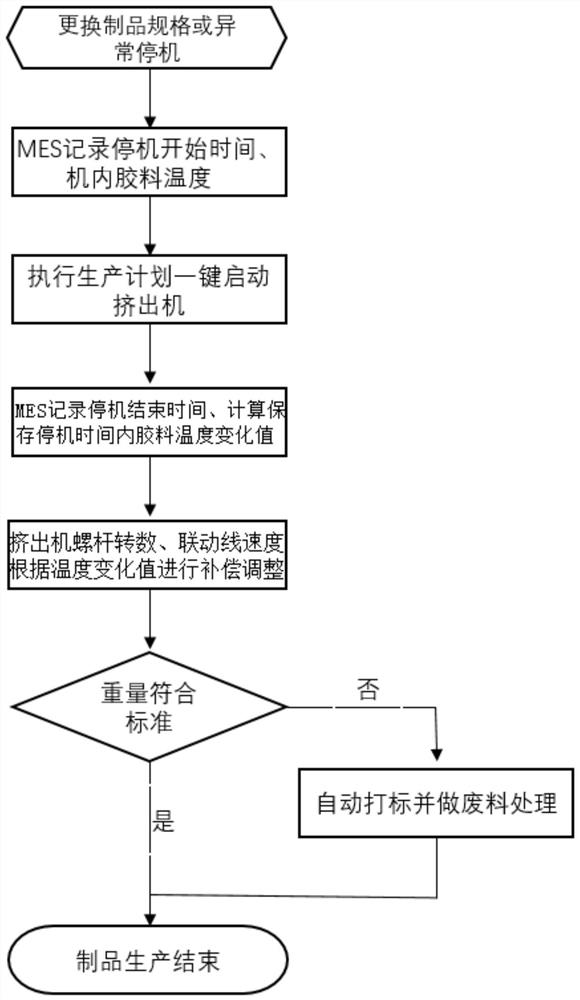

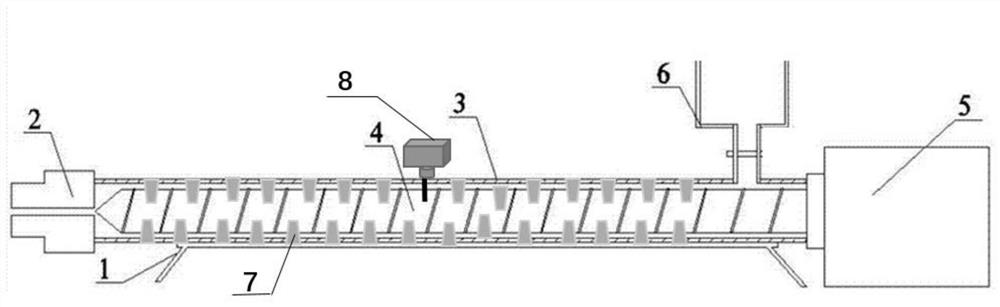

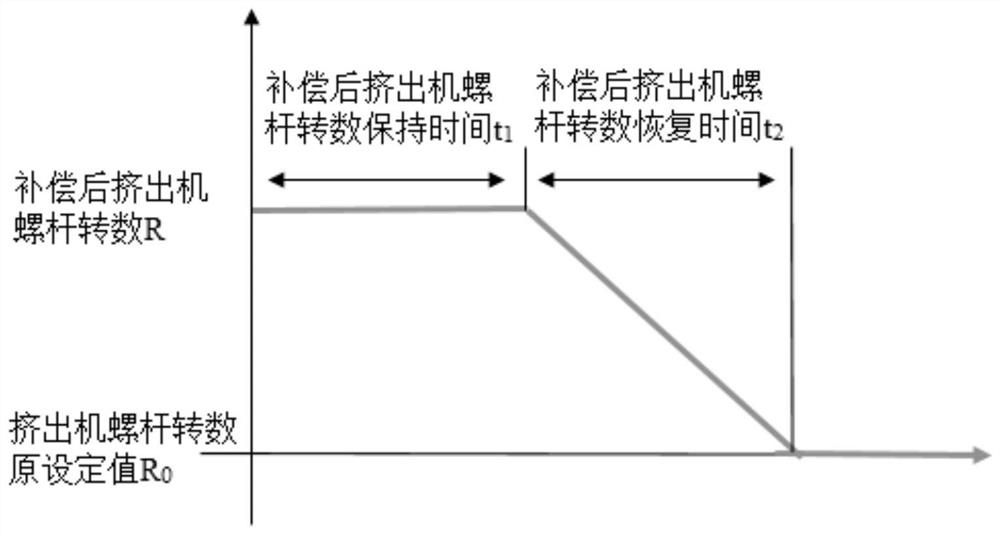

Control method for presetting rotation number of screw of extruder

The invention discloses a control method for presetting a rotation number of a screw of an extruder. A temperature sensor for measuring the temperature of a sizing material is mounted in the extruder;and the extruder and the temperature sensor are both connected to a MES system. The control method comprises the steps that: the MES system measures and records the temperature of the sizing materialin the stop period of time of the extruder; the MES system compensates an extruder screw rotation number set value R0 and a linkage line speed set value V0 according to a temperature change value delta T of the sizing material in the stop time; and lasting time t1 and recovery time t2 of an extruder screw rotation number R and a linkage line speed V after compensation are set. On the basis of effective cooperation among the MES system, the extruder and a linkage line, the extruder screw rotation number and the linkage line speed are compensated according to the temperature change of the sizing material in the extruder, so that the weight value of products extruded by the extruder after one-key startup is quickly stabilized, the reject ratio of the products of the sizing material is greatly reduced, and the problems of long fluctuation time and great fluctuation amplitude of the weight value of the products of the sizing material after one-key startup in the prior art are effectively solved.

Owner:SAILUN GRP CO LTD

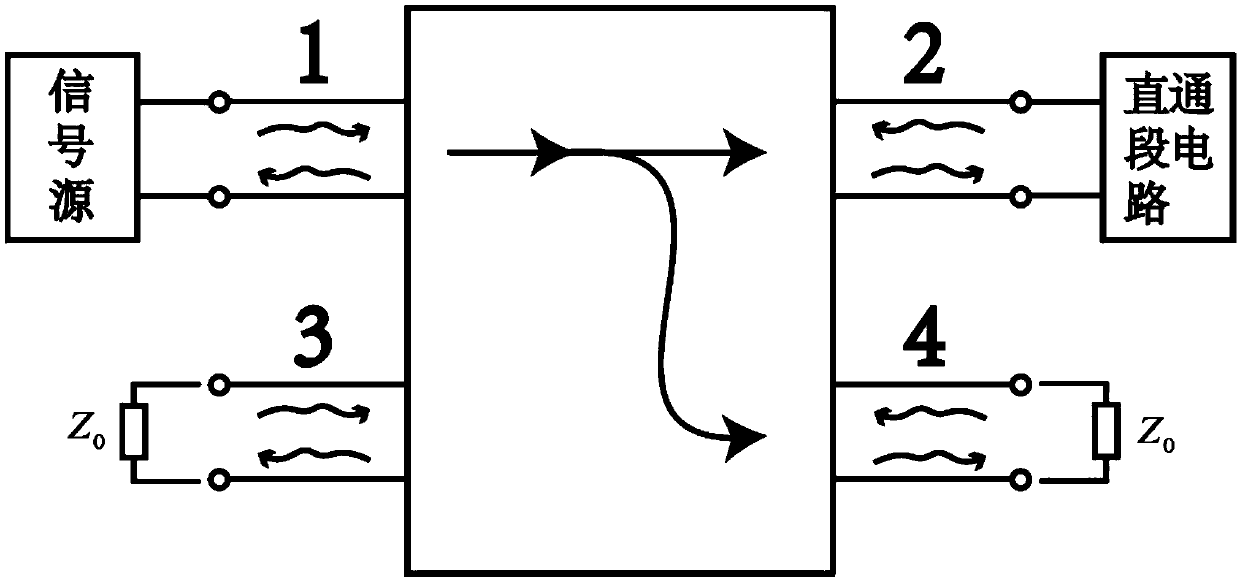

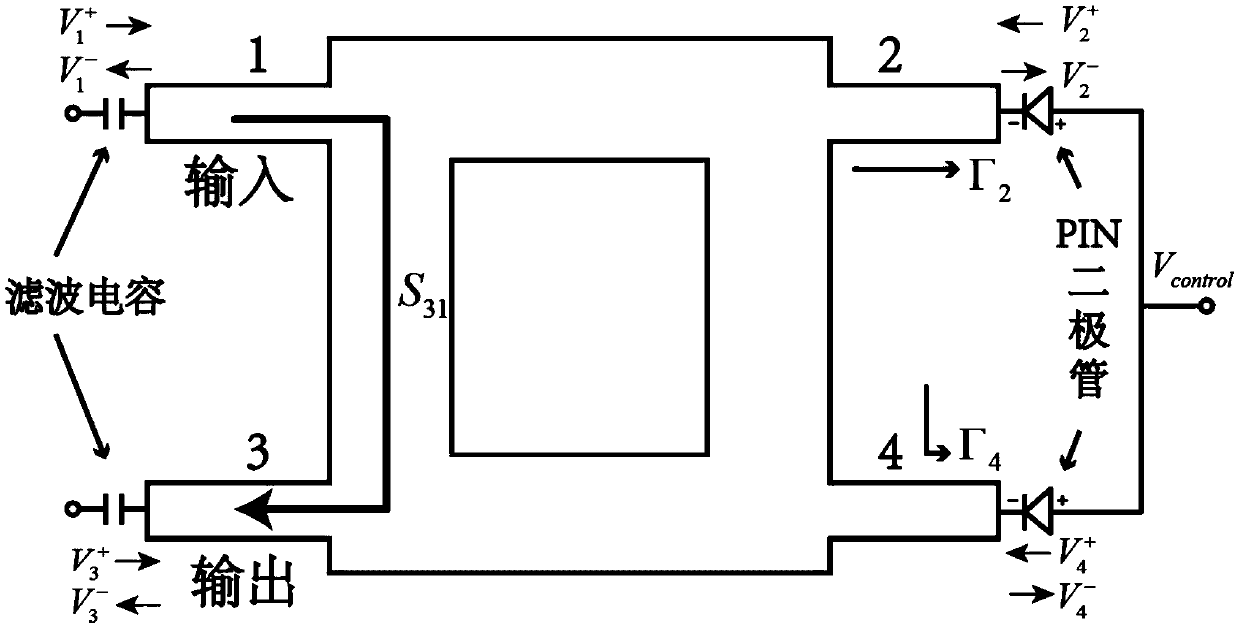

A microwave or millimeter wave amplitude and phase control circuit based on a directional coupler

InactiveCN109004365ASimultaneous adjustment rangeSimultaneously adjust the phaseAntenna arraysAutomatic controlWave field

The invention discloses a microwave or millimeter wave amplitude and phase control circuit based on a directional coupler. By adding a PIN transistor or a JFET transistor operating in the microwave ormillimeter band to the through port and coupling port of a conventional directional coupler, By controlling the DC bias voltage across the positive and negative terminals of the PIN transistor or theDC bias voltage from the gate g of the JFET transistor to the two terminals of the source s, the reflection coefficient of the through port and the coupling port can be changed, and the S-parameter distribution of the four-port network of the directional coupler can be influenced. The invention realizes the function of amplitude modulation and phase modulation of the radio frequency signal in thecircuit at the same time, The invention reduces the dependence of millimeter band communication on high-cost TR module, solves the engineering problem of automatic control and adjustment of RF signalamplitude and phase in microwave or millimeter wave field, simplifies the circuit, avoids the combination of analog devices in traditional amplitude and phase control circuit, and reduces the cost.

Owner:ZHEJIANG UNIV

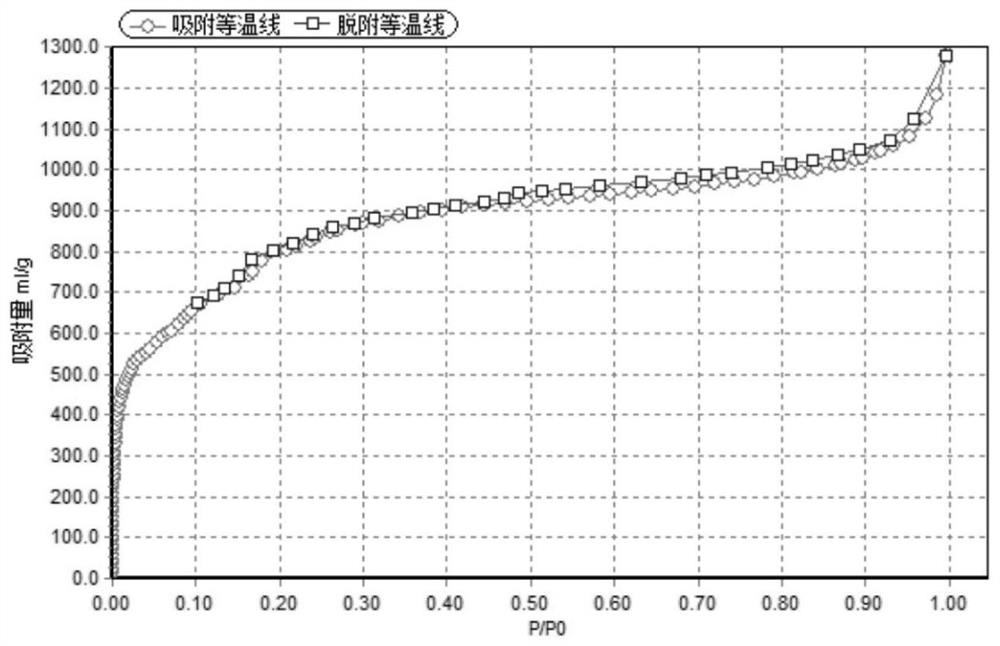

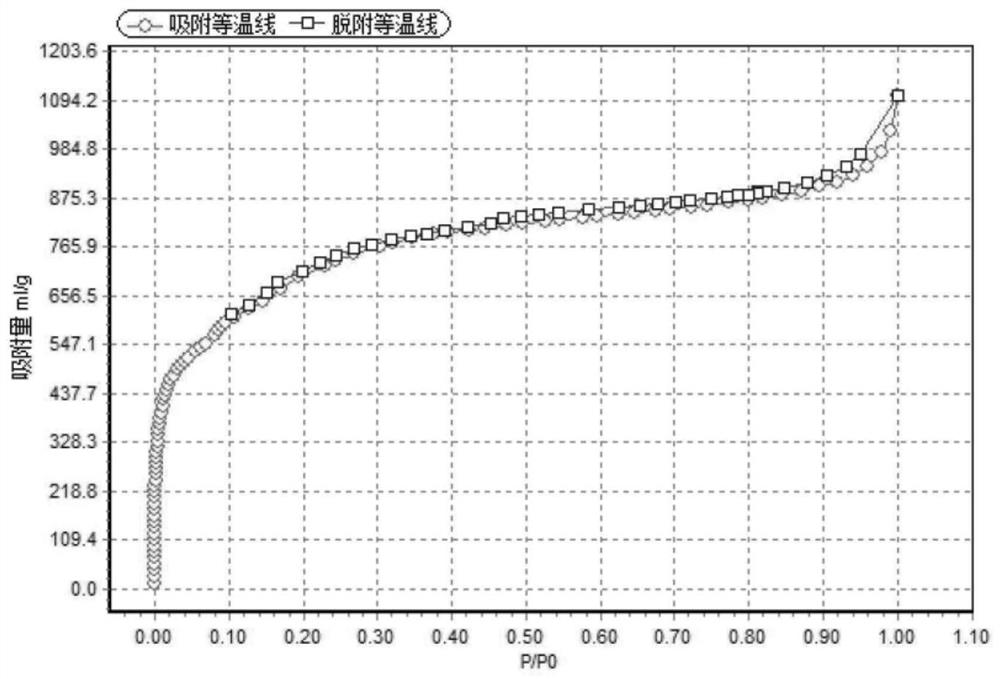

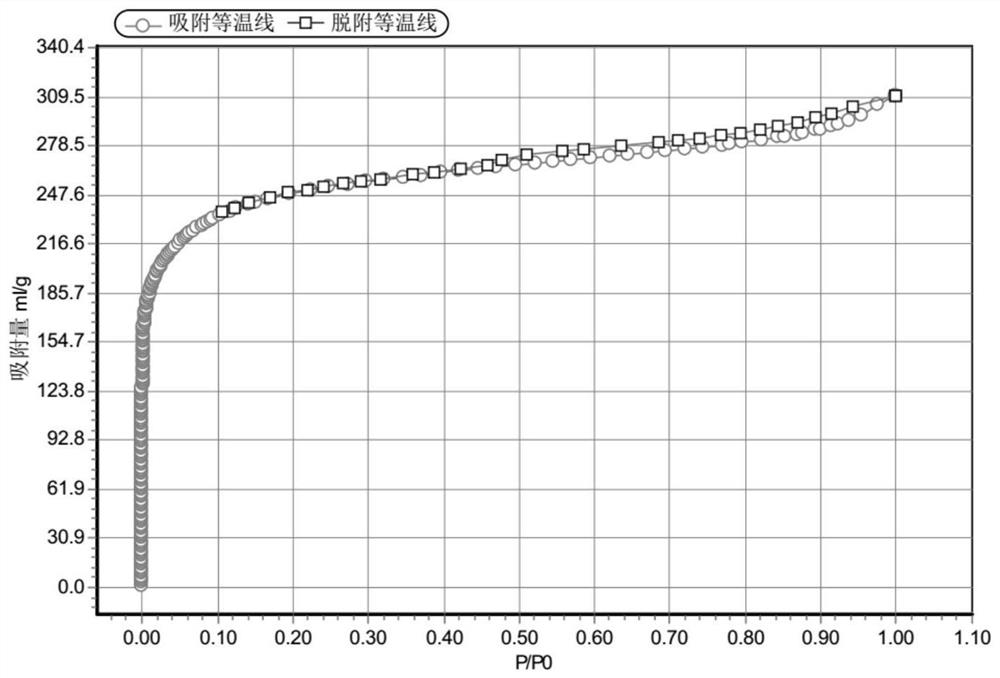

Composite material with benzene series adsorption function, preparation method of composite material, method for removing benzene series by using composite material and application of composite material

PendingCN114100581AHigh mechanical strengthLarge hole volumeGas treatmentOther chemical processesPolyvinyl alcoholPolyamide

The invention relates to the field of material synthesis, and discloses a composite material with a benzene series adsorption function, a preparation method of the composite material, a method for removing benzene series by using the composite material and application of the composite material. The composite material comprises an association structure formed by a polymer and an iron-based metal organic framework material loaded in the association structure, the weight ratio of the polymer to the iron-based metal organic framework material is 1: (1-20), and the polymer is selected from at least one of polyether sulfone, polyvinyl formal, polypropylene, polyethylene sulfone and polyamide. Through the synergistic effect of the two components in the composite material, the composite material is stable in framework structure and has high mechanical stability, the pore volume, the pore diameter and the specific surface area of the composite material are large, the composite material has high benzene series adsorption capacity, the method for preparing the composite material is simple and environmentally friendly, the price of synthetic raw materials is low, and the composite material is suitable for industrial production. The large-scale production and application are easy.

Owner:CHINA PETROLEUM & CHEM CORP +1

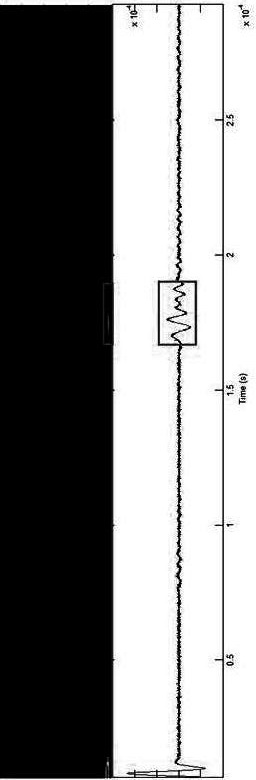

Rock debris scatterer identification method in measurement of while-drilling well diameter

PendingCN112282739AResolution rangeResolve identifiabilitySurveyConstructionsWell drillingWell logging

The invention discloses a rock debris scatterer identification method in measurement of while-drilling well diameter, and belongs to the technical field of oil and gas drilling. The rock debris scatterer identification method is characterized by comprising the following steps that a, time-frequency dimension expansion of a signal is carried out, time-frequency analysis is carried out on the while-drilling signal by adopting short-time processing, a sampling point with the frame size being 512 is selected, and the frame shift is half of the frame size; the one-dimensional signal is expanded toa two-dimensional signal; b, based on learning of signal features of machine learning, a Yolo network model is constructed to learn reflection signal features in ultrasonic logging on the basis of expanded training set pictures; and c, reflector identification is carried out. The rock debris scatterer identification method adopts rock debris reflector identification based on machine learning, thediscrimination accuracy is high, does not depend on subjective experience of people and is more objective, the accuracy of borehole diameter measurement is greatly improved, and the universality is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com