Heat-resistant super-ductility polyethylene terephthalate (PET) compound and preparation method thereof

A technology of polyethylene terephthalate and ductility, applied in the field of polyethylene terephthalate compound and its preparation, can solve the problem of heat resistance and tensile property curve without sharp yield point and yield stress and modulus increase, elongation at break and other problems, to achieve the effect of good ductility, high notched impact strength and super ductility, excellent super ductility and high impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

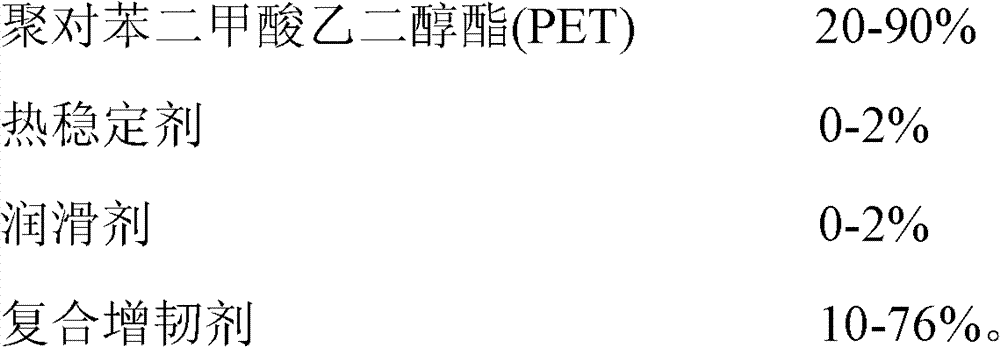

Method used

Image

Examples

Embodiment 1

[0019] 68 kg of polyethylene terephthalate (PET), 0.5 kg of heat stabilizer 1010, 0.5 kg of antioxidant 168, 1 kg of processing aid calcium stearate, 10 kg of ethylene-acrylate-methacrylic acid Glyceride (PTW), 10 kilograms of LLDPE, and 10 kilograms of SEBS are melt-mixed and dispersed in a twin-screw extruder with an aspect ratio of 1:40. The extrusion temperature is 240° C., extruded and granulated, and finally the product is obtained.

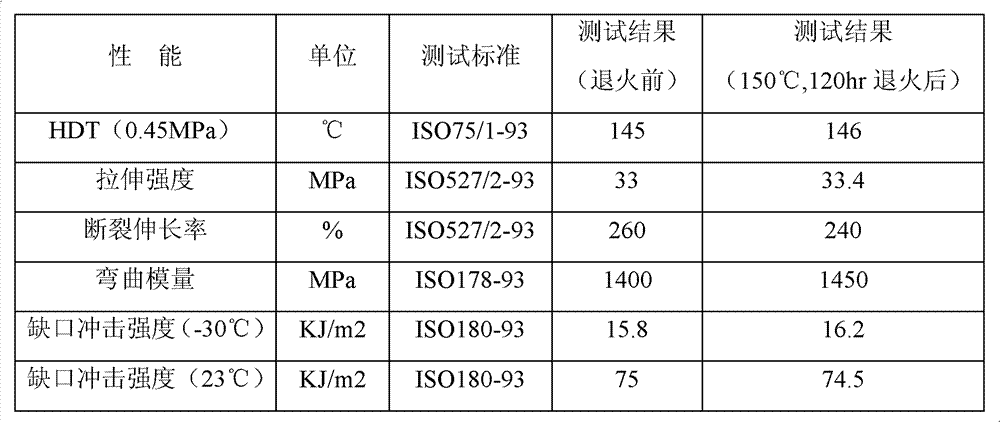

[0020] The product of the present invention has excellent heat resistance, good ductility and impact performance, its elongation at break can reach 200%, tensile strength ≥ 30MPa, flexural modulus ≥ 1200MPa, normal temperature (23°C) notched impact strength ≥ 45KJ / m 2 , low temperature (-30°C) notched impact strength ≥ 10KJ / m 2 , heat distortion temperature (0.45MPa) ≥ 140 ° C, 150 ° C after annealing for 120 hours, its mechanical properties are almost unchanged. The performance is as follows:

[0021]

Embodiment 2

[0023] 73 kilograms of polyethylene terephthalate (PET), 0.6 kilograms of heat stabilizer 1010, 0.4 kilograms of antioxidant 168, 1 kilogram of processing aid EBS, 10 kilograms of ethylene-acrylate-glyceryl methacrylate ( PTW), 8 kilograms of LLDPE, and 7 kilograms of SEBS are melted and mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 1: 40. The extrusion temperature is 240° C., extruded and granulated, and finally obtained the product.

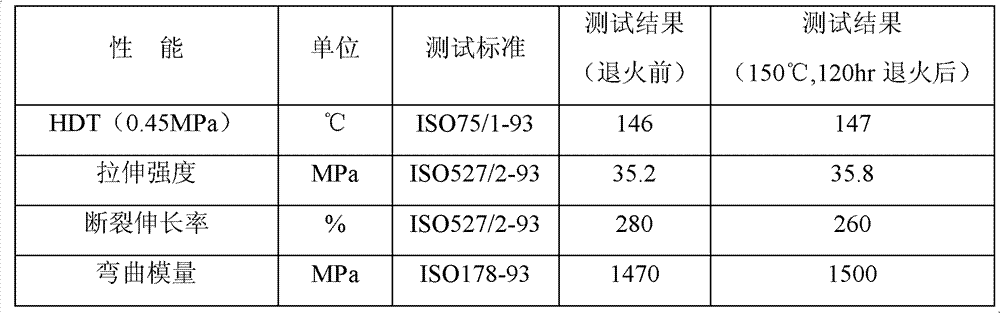

[0024] The product of the present invention has excellent heat resistance, good ductility and impact performance, its elongation at break can reach 200%, tensile strength ≥ 30MPa, flexural modulus ≥ 1200MPa, normal temperature (23°C) notched impact strength ≥ 45KJ / m 2 , low temperature (-30°C) notched impact strength ≥ 10KJ / m 2 , heat distortion temperature (0.45MPa) ≥ 140 ° C, 150 ° C after annealing for 120 hours, its mechanical properties are almost unchanged. The performance is as follows:

[0025]

...

Embodiment 3

[0028] 75 kilograms of polyethylene terephthalate (PET), 1.0 kilograms of heat stabilizer 1010, 0.8 kilograms of antioxidant 168, 0.2 kilograms of processing aid EBS, 12 kilograms of ethylene-acrylate-glyceryl methacrylate ( PTW), 5 kilograms of LDPE, and 6 kilograms of SBS are melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 1:40, and the extrusion temperature is 240° C., extruded and granulated, and finally obtained the product.

[0029] The product of the present invention has excellent heat resistance, good ductility and impact performance, its elongation at break can reach 200%, tensile strength ≥ 30MPa, flexural modulus ≥ 1200MPa, normal temperature (23°C) notched impact strength ≥ 45KJ / m 2 , low temperature (-30°C) notched impact strength ≥ 10KJ / m 2 , heat distortion temperature (0.45MPa) ≥ 140 ° C, 150 ° C after annealing for 120 hours, its mechanical properties are almost unchanged. The performance is as follows:

[0030] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com