Preparation method of functional high-viscosity slice for monofilaments

A functional and high-viscosity technology, applied in the direction of single-component polyester rayon, etc., can solve the problems affecting the uniformity of monofilament strength and color, the high cost of adding color masterbatch chips, and the unstable content of color additives. and other problems, to achieve the effect of round and smooth surface, small diameter deviation and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

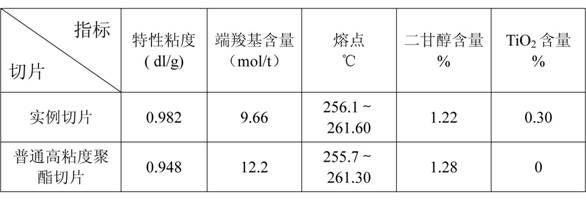

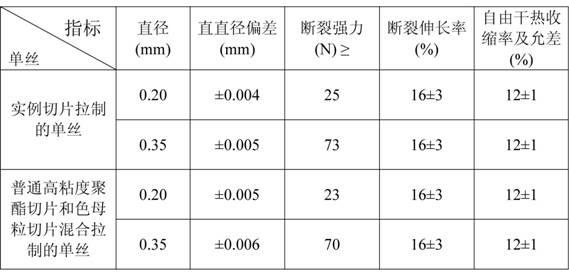

Examples

Embodiment

[0020] Add PTA, EG, TiO to 90t / day polyester production line 2 , triethyl phosphate, catalyst ratio is 860: 340: 3.0: 0.086: 0.28. The esterification reaction temperature is 250-275°C, the absolute pressure is 0.1-0.3MPa, and the reaction time is 2.5-4 hours; the polycondensation temperature is 265-295°C, the absolute pressure is ≤20KPa, and the reaction time is 4.5-6.5 hours. Functional low-viscosity polyester chips become functional low-viscosity polyester chips after pelletizing and drying.

[0021] In the 90 tons / day solid-state polycondensation production line, functional low-viscosity polyester chips are used as raw materials to produce functional high-viscosity chips for monofilament. The pre-crystallization temperature is 150-160°C, and the time is 15 minutes to 1 hour; the crystallization temperature is 170-185°C, and the time is 15 minutes to 1 hour; the preheating temperature is 210-230°C, and the time is 5-6 hours; polycondensation The temperature is 190-210°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com