Production method for linear alkylbenzenes

A technology of linear alkylbenzene and its production method, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, addition of unsaturated hydrocarbons and saturated hydrocarbons to produce hydrocarbons, etc. It can solve problems such as equipment corrosion and reduce energy consumption. consumption, reduce investment, and solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

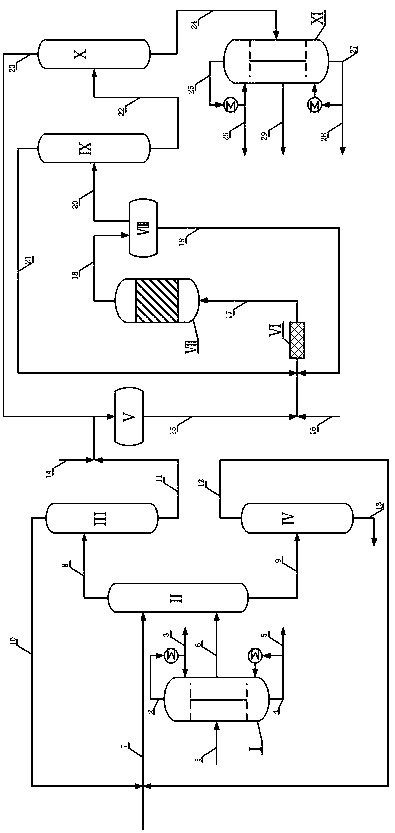

[0024] The process of the method for the present invention to produce linear alkylbenzene is as follows:

[0025] Adopt technology of the present invention, take the long-chain alkene that the Fischer-Tropsch synthesis method makes as raw material, wherein the mass fraction of the normal alkene of 10~13 carbon atoms is 23%, the mass fraction of oxygen-containing impurity amount is 6%, requires The mass fraction of water in commercially available benzene raw materials is below 0.1%.

[0026] Such as figure 1 As shown, after pretreatment in the next-door column The mass fraction of n-paraffin olefin fractions with 10-13 carbon atoms in stream 6 obtained by cutting is 60%, and the mass fraction of oxygen-containing impurities is 3%. Pretreatment next door tower The operating conditions are as follows: the operating pressure is 0.005MPa, the operating temperature at the top of the tower is 54°C, the operating temperature at the bottom of the tower is 106°C, and the theoretica...

example 2

[0033] By adopting the process of the present invention, the long-chain alkanes obtained by the Fischer-Tropsch synthesis method are used as raw materials, and the Fischer-Tropsch synthetic oil contains n-alkanes with 2 to 20 carbon atoms, of which n-alkanes with 10 to 13 carbon atoms The mass fraction of oxygen-containing impurities is 26%, and the mass fraction of oxygen-containing impurities is 5%. The benzene raw material is commercially available, wherein the mass fraction of water is below 0.1%.

[0034] Pretreated next door tower The mass fraction of n-paraffin olefins with 10-13 carbon atoms in stream 6 obtained by cutting is 63%, and the mass fraction of oxygen-containing impurities is 2%. Pretreatment next door tower The operating conditions are as follows: the operating pressure is 0.01MPa, the operating temperature at the top of the tower is 61°C, and the operating temperature at the bottom of the tower is 112°C. 16, 25, 32, 23.

[0035] Logistics 6 and logis...

example 3

[0041] By adopting the process of the present invention, the long-chain alkene obtained by the Fischer-Tropsch synthesis method is used as a raw material. The Fischer-Tropsch synthetic oil contains n-alkene with 2 to 20 carbon atoms, and n-alkane with 10 to 13 carbon atoms. The mass fraction of olefins is 25%, and the mass fraction of oxygen-containing impurities is 6%. Benzene raw material is commercially available.

[0042] pass the next tower The mass fraction of n-paraffin olefins with 10-13 carbon atoms in stream 6 obtained by cutting is 68%, and the mass fraction of oxygen-containing impurities is 2%. next door tower The operating conditions are as follows: the operating pressure is 0.015MPa, the operating temperature at the top of the tower is 67°C, and the operating temperature at the bottom of the tower is 130°C. 18, 28, 34, 24.

[0043] Logistics 6 and logistics 7 are separated from the extraction tower The bottom and the top of the stream enter, and the stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com