Wavelength-tunable multi-wavelength laser production system and method

A multi-wavelength, laser technology, applied in the direction of electromagnetic wave transmission system, transmission system, electromagnetic transmitter, etc., can solve the problems of complex operating point control logic of the modulator, optical signal insertion loss, poor stability, etc., and achieve flexible beam spacing. Continuous tuning, solving the effect of large difference in multi-wavelength amplitude and increasing the number of wavelengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

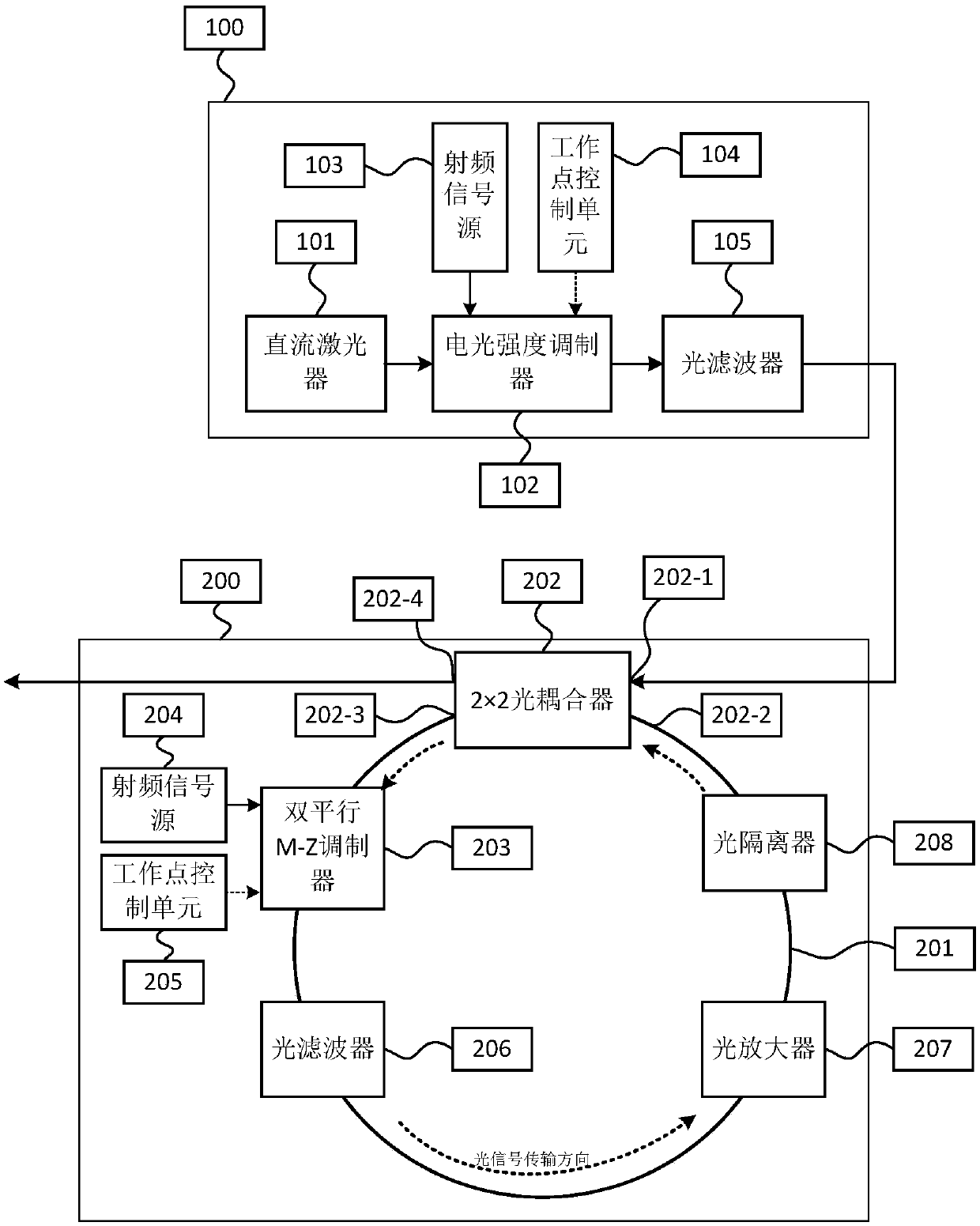

Method used

Image

Examples

Embodiment

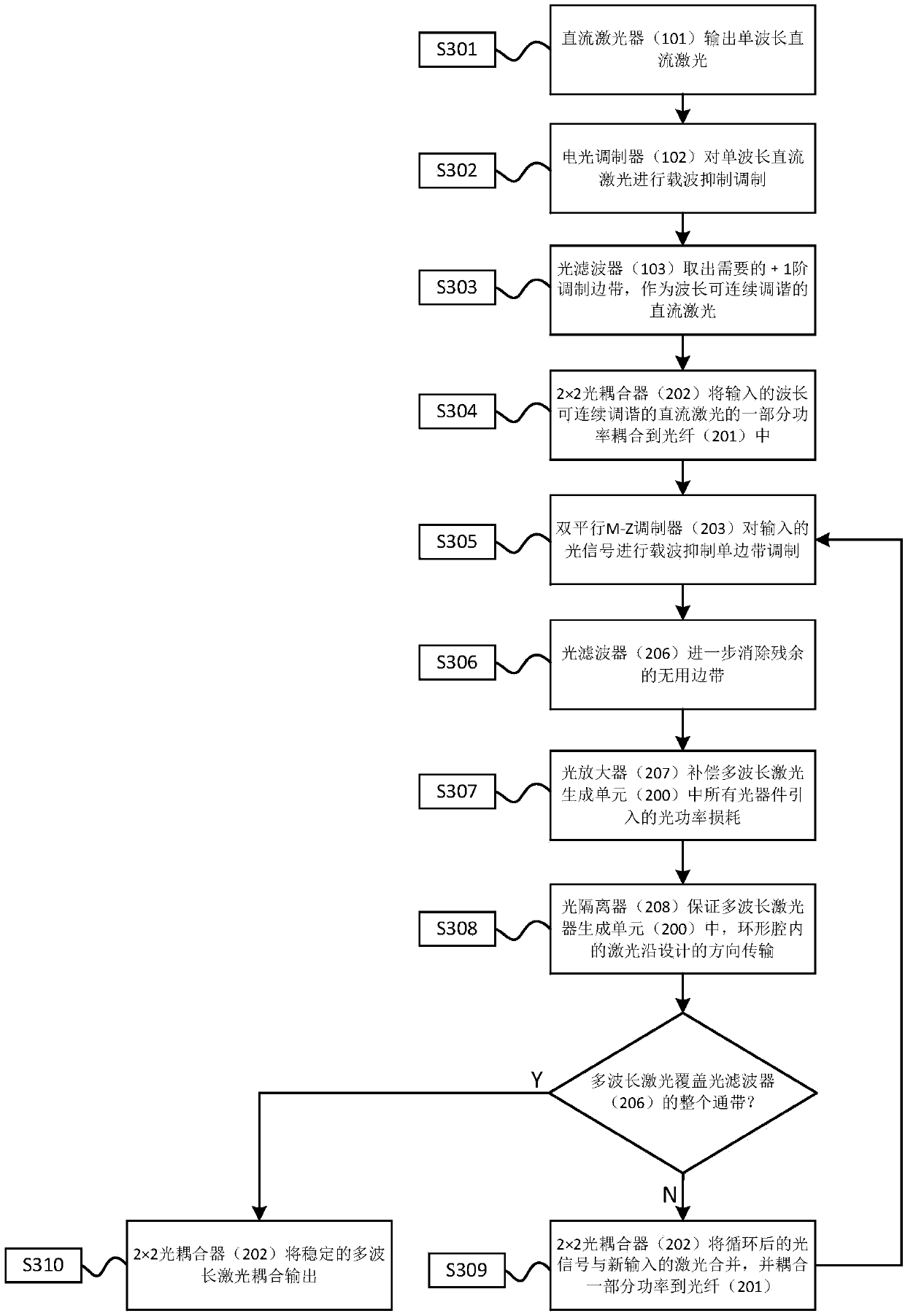

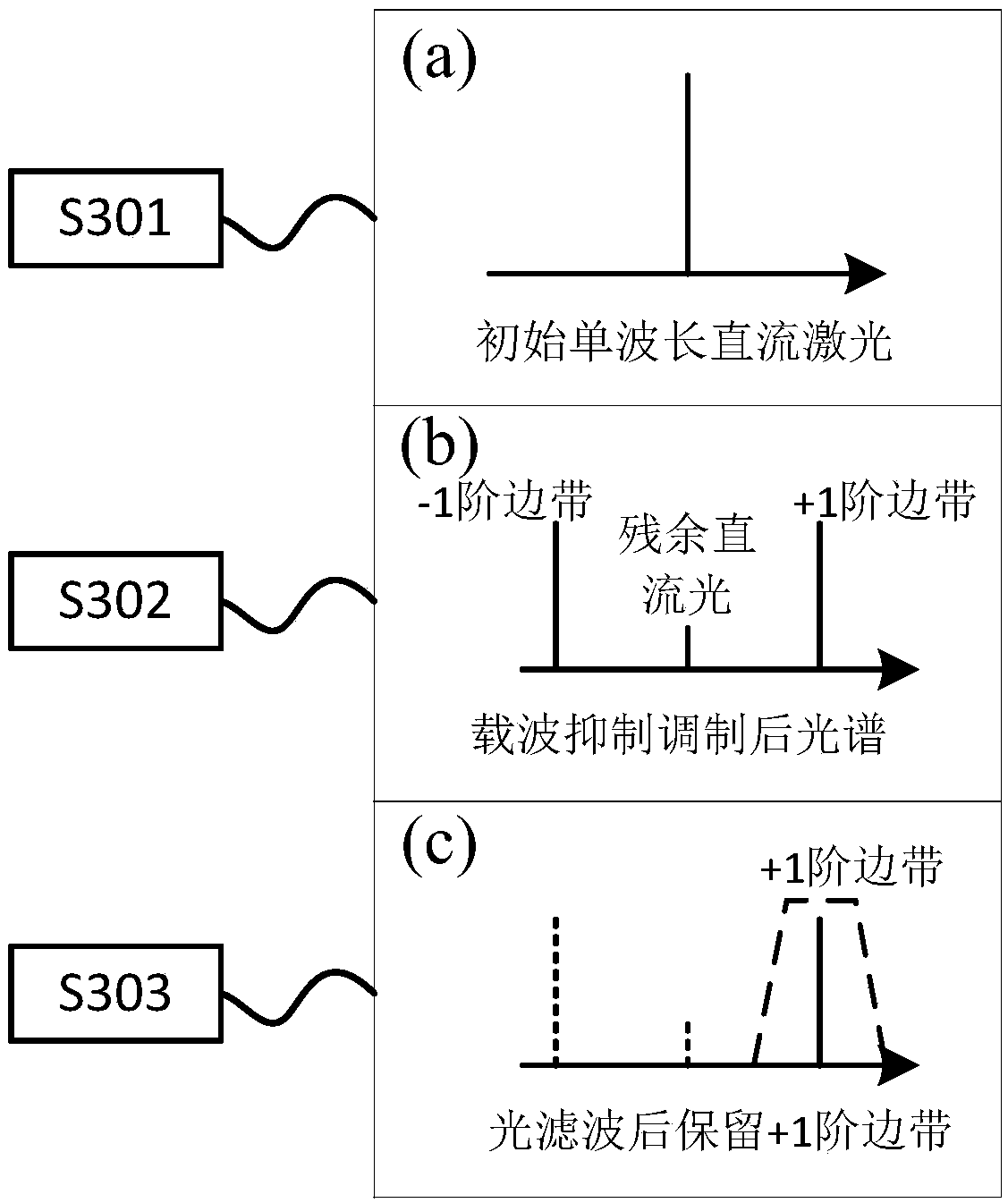

[0087] A specific implementation example of the wavelength-tunable multi-wavelength laser generation method provided by the present invention is as follows:

[0088] (1) Start the whole device. In the tunable DC laser generating unit: the DC laser outputs DC laser with a frequency of 193.200THz and transmits it to the first electro-optic intensity modulator, the first RF signal source outputs a 10GHz RF signal, and the first operating point control unit outputs a control signal to enable The first electro-optical intensity modulator works in a carrier suppression modulation state. At this time, the first electro-optical intensity modulator will output optical signals with the following frequency values: the -1st order modulation sideband with a frequency of 193.190THz, the initial DC laser with a small residual amplitude of 193.200THz, and the frequency of 193.210THz +1 order modulation sidebands at THz. After the above-mentioned optical signal passes through the first optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com