A supporting mechanism for achieving three -dimensional space movement

A driving mechanism and three-dimensional space technology, applied in the direction of transmission devices, mechanical equipment, lifting devices, etc., can solve problems such as limited transmission height, easy gaps, and insufficient structural stability, and achieve simplified hinges, extended service life, and structural stability. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments of the present invention and the accompanying drawings. Obviously, the described embodiments do not limit the present invention.

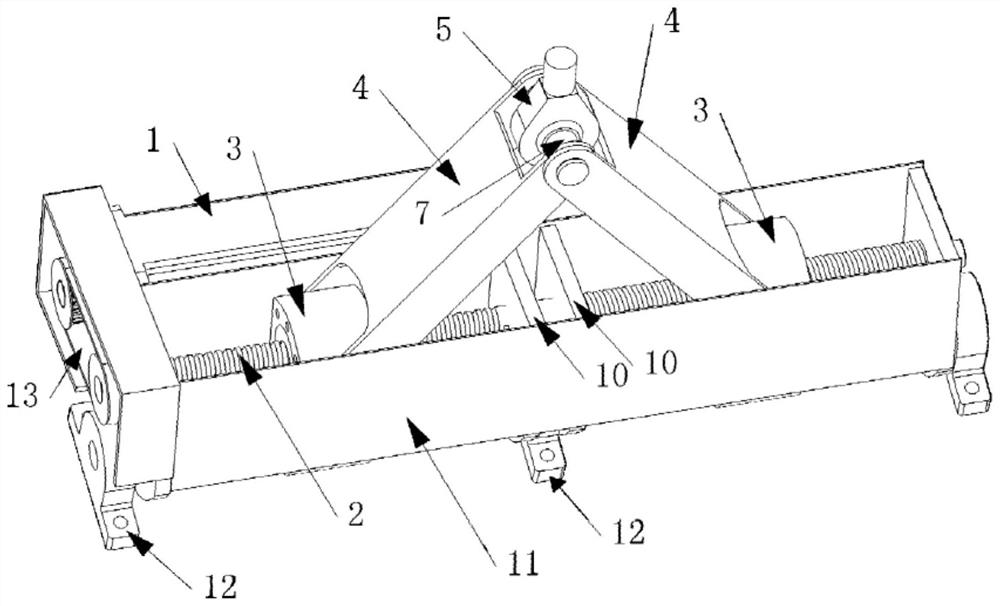

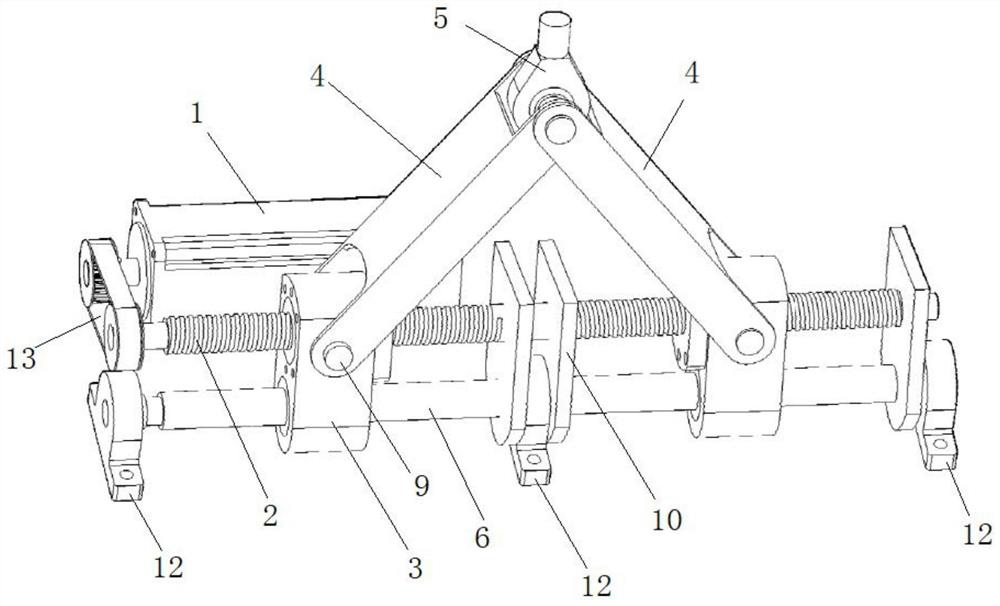

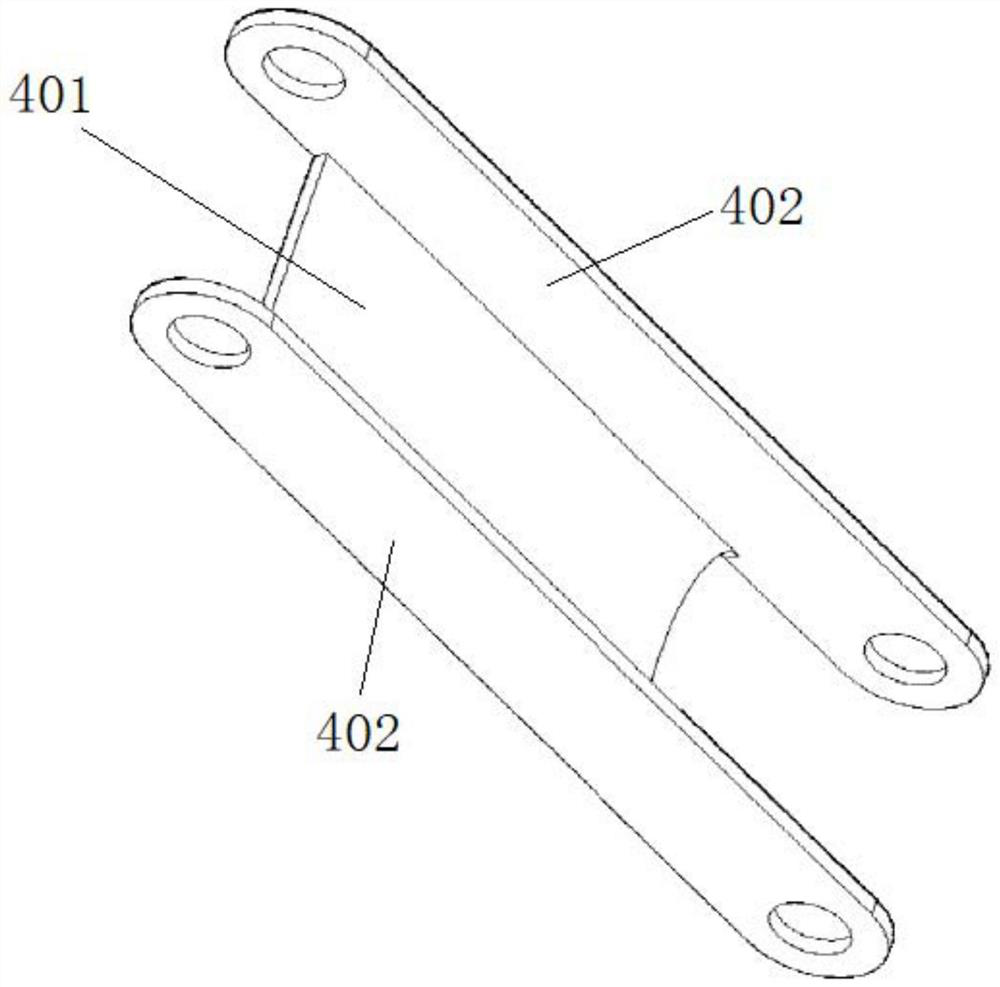

[0041] like Figure 1 to Figure 5 , a support drive mechanism for realizing three-dimensional space motion, including a drive unit 1, a screw 2, a joint bearing 5, a guide support rod 6, a partition 10, a mounting frame 11, a mounting seat 12, two sliders 3 and two A support 4.

[0042] The output end of the drive unit 1 is connected to the screw 2, and the drive unit 1 is used to drive the screw 2 to rotate. The drive unit 1 can use a rotating motor, which can be directly connected to the screw 2, or can be connected through a transmission component, such as through a synchronous belt 13, a chain Or gear with etc. for transmission.

[0043] The screw 2 is provided with two threads with opposite directions of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com