Linkage-transmission rotating and lifting mechanism

A technology of rotating lifting and connecting rod transmission, applied in the direction of lifting devices, etc., can solve problems such as damage to rotating parts and failure to meet the functional requirements of innovative products, and achieve the effects of improving stability, improving operating experience, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited to the following specific examples.

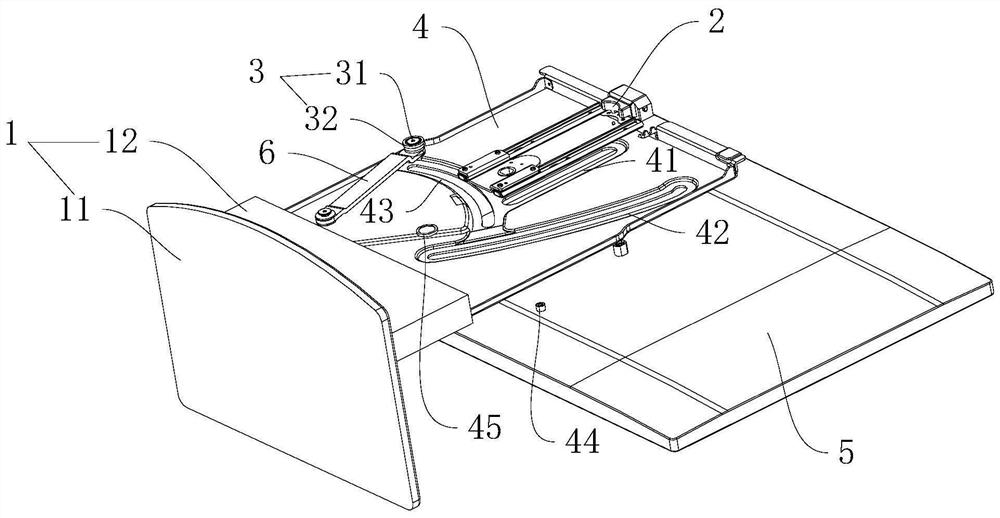

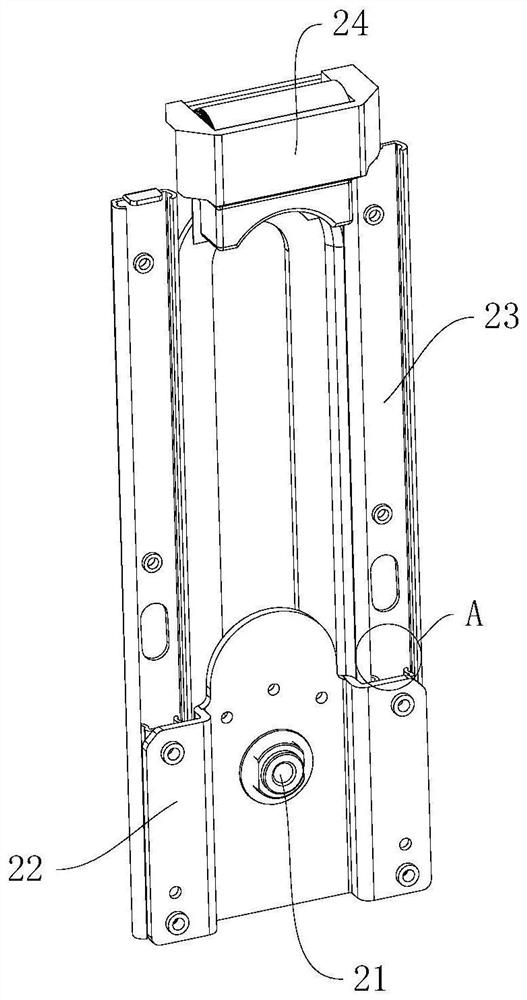

[0038] refer to figure 1 , the present embodiment discloses a connecting rod 6 transmission rotation lifting mechanism, including a fixed base 1 , a fixed plate 4 , a rotating member 5 , a lifting assembly 2 , a rotating assembly 3 and a connecting rod 6 .

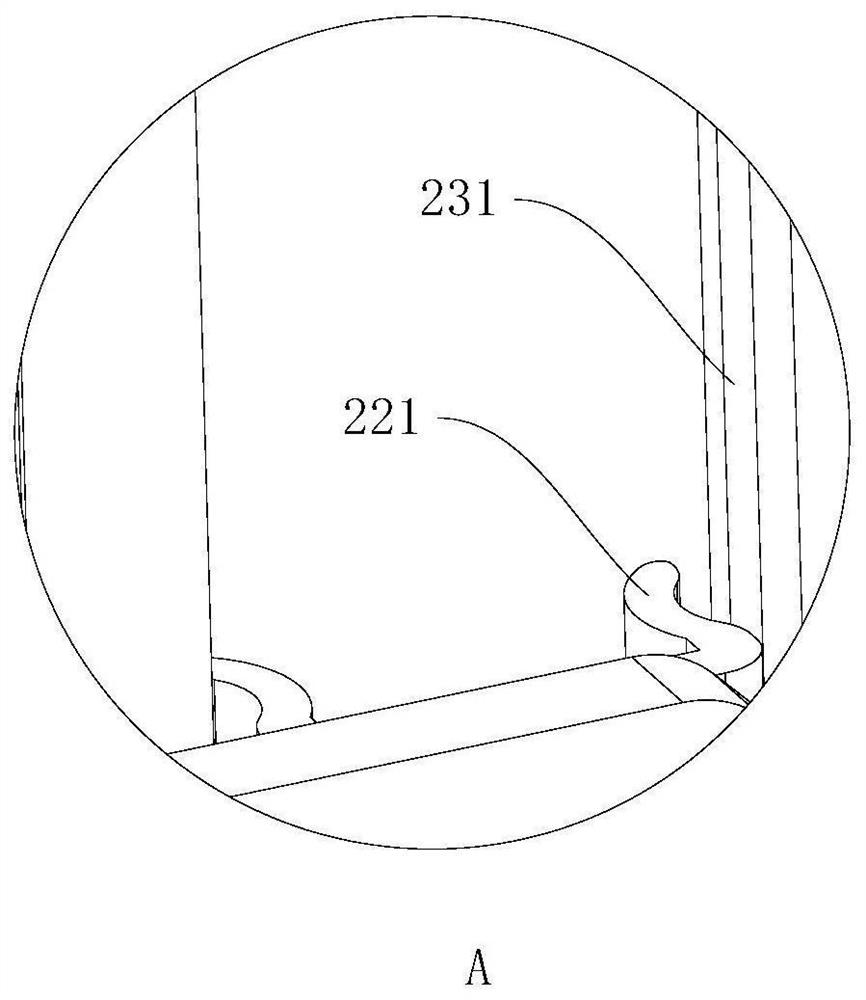

[0039] refer to figure 1 , the fixing base 1 includes a base plate 11 and a support plate 12 vertically fixed to the base plate 11 , and the fixing plate 4 is fixedly connected to the top of the support plate 12 . The support plate 12 is respectively provided with a lifting slideway 41, a rotating slideway 42 and a balancing slideway 43 that run through the supporting plate 12, wherein the rotating slideway 42 and the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap