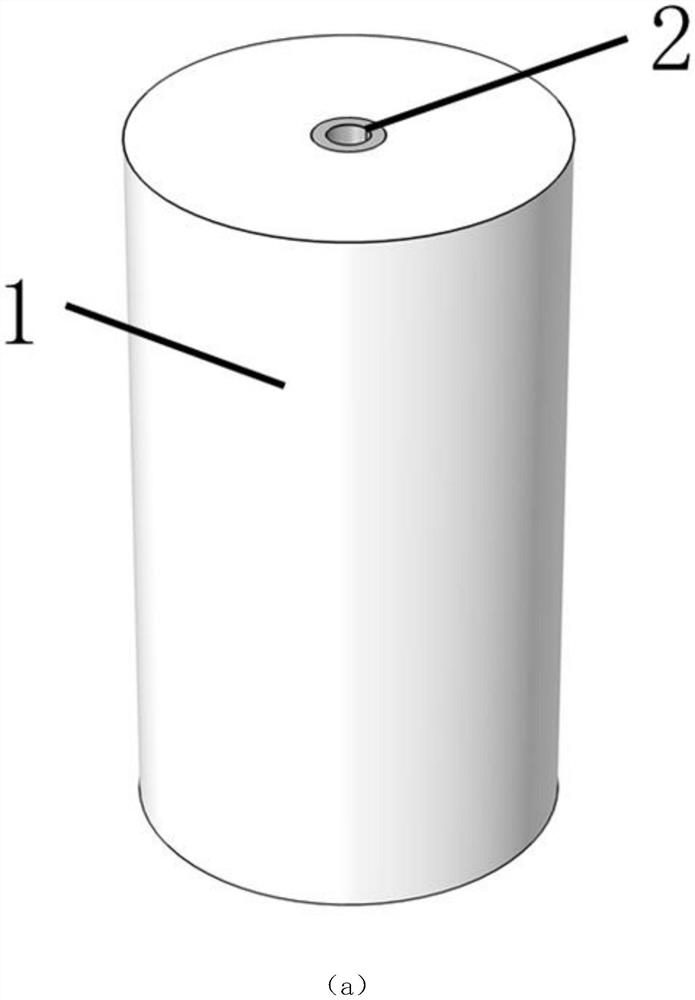

Damping layer modified underwater sound absorption inner insertion pipe type Helmholtz resonance cavity structure

A damping layer, intubation type technology, applied in the field of acoustic metamaterials, can solve the problems of poor bearing performance, poor low-frequency sound absorption performance, heavy weight, etc., to improve low-frequency sound absorption performance, excellent low-frequency sound absorption performance, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

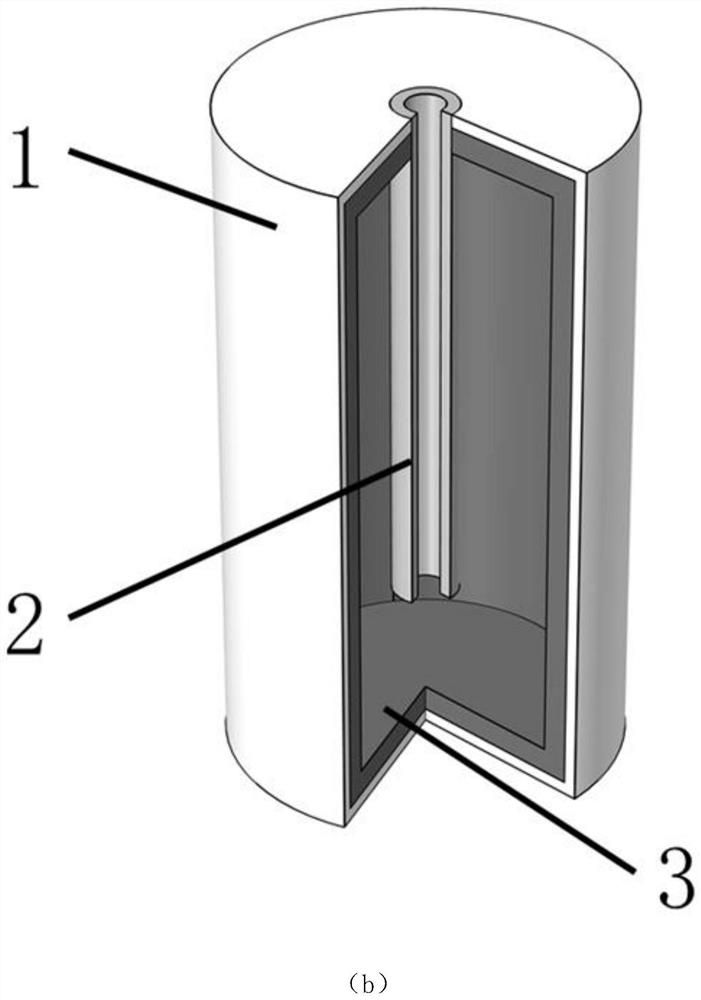

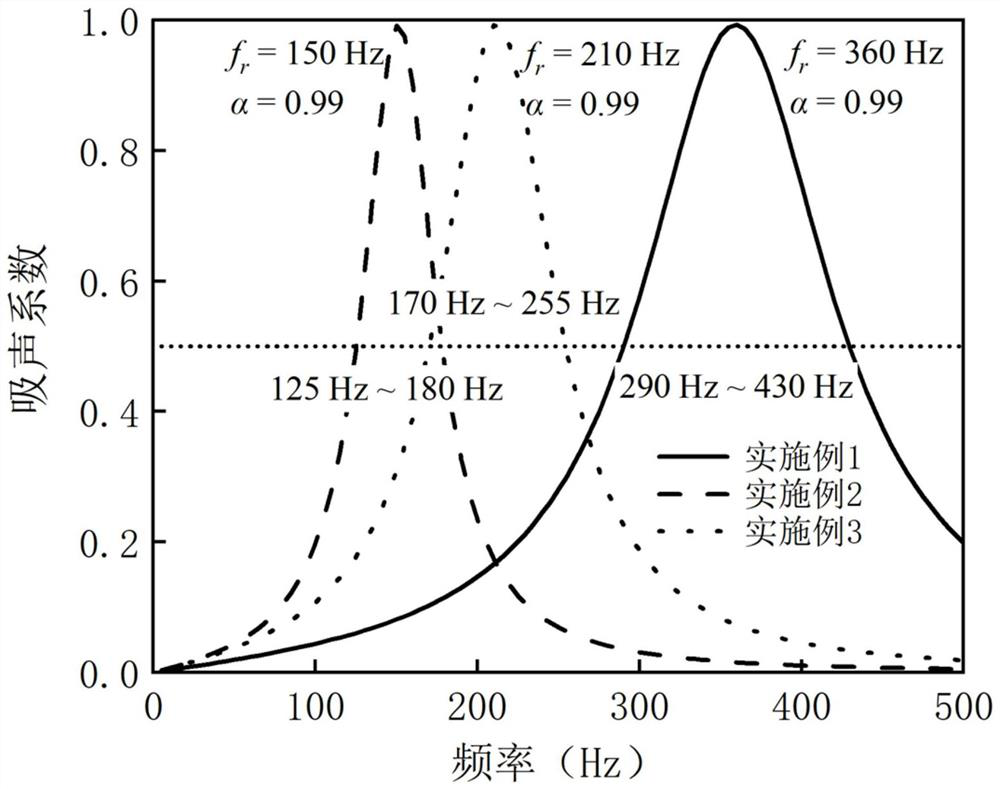

[0044] The diameter of the cavity is 32mm, the height of the cavity is 30mm, the diameter of the inner tube is 3mm, the length of the inner tube is 25mm, and the thickness of the damping lining is 2mm.

Embodiment 2

[0046] The diameter of the cavity is 50mm, the height of the cavity is 40mm, the diameter of the inner tube is 4mm, the length of the inner tube is 30mm, and the thickness of the damping lining is 4mm.

Embodiment 3

[0048] The diameter of the cavity is 40mm, the height of the cavity is 50mm, the diameter of the inner tube is 2.5mm, the length of the inner tube is 35mm, and the thickness of the damping lining is 3mm.

[0049] see figure 2 , the Helmholtz resonance phenomenon at low frequencies can achieve perfect sound absorption in a certain frequency range. By pasting the damping lining layer on the inner wall of the resonance cavity, the acoustic impedance characteristics of the structure are improved, and the rubber layer provides additional acoustic resistance and sound capacity, forming a Helmholtz-like resonance, so that the invention realizes perfect underwater low frequency sound absorption.

[0050] see figure 2 , the sound absorption coefficient of Example 1 is greater than 0.5 at 125-180 Hz, the half-sound absorption bandwidth is 37%, and perfect sound absorption is achieved at 150 Hz, and the peak value of the sound absorption coefficient is 0.99, which realizes perfect ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com