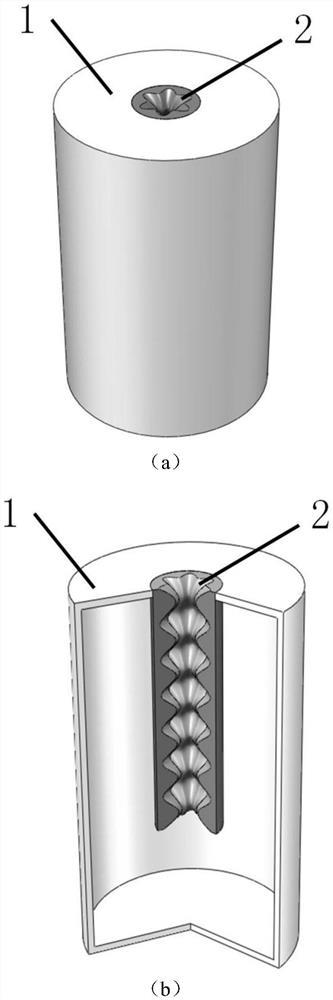

Bidirectional rough inner insertion tube type Helmholtz resonance sound absorption structure

A technology of resonant sound absorption and intubation, which is applied in the direction of sound-emitting devices and instruments, and can solve the problems of poor low-frequency sound absorption, difficulty in light weight, and difficulty in manufacturing, so as to improve acoustic impedance characteristics and enhance low-frequency Sound-absorbing characteristics and the effect of ensuring load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Examples of materials:

[0052] Alloy steel: characterized by a density of 7820kg / m 3 , Young's modulus 206GPa, Poisson's ratio 0.29.

[0053] Air: characterized by a density of 1.29kg / m 3 , sound velocity 343m / s, dynamic viscosity coefficient 1.81×10 -5 Pa·s.

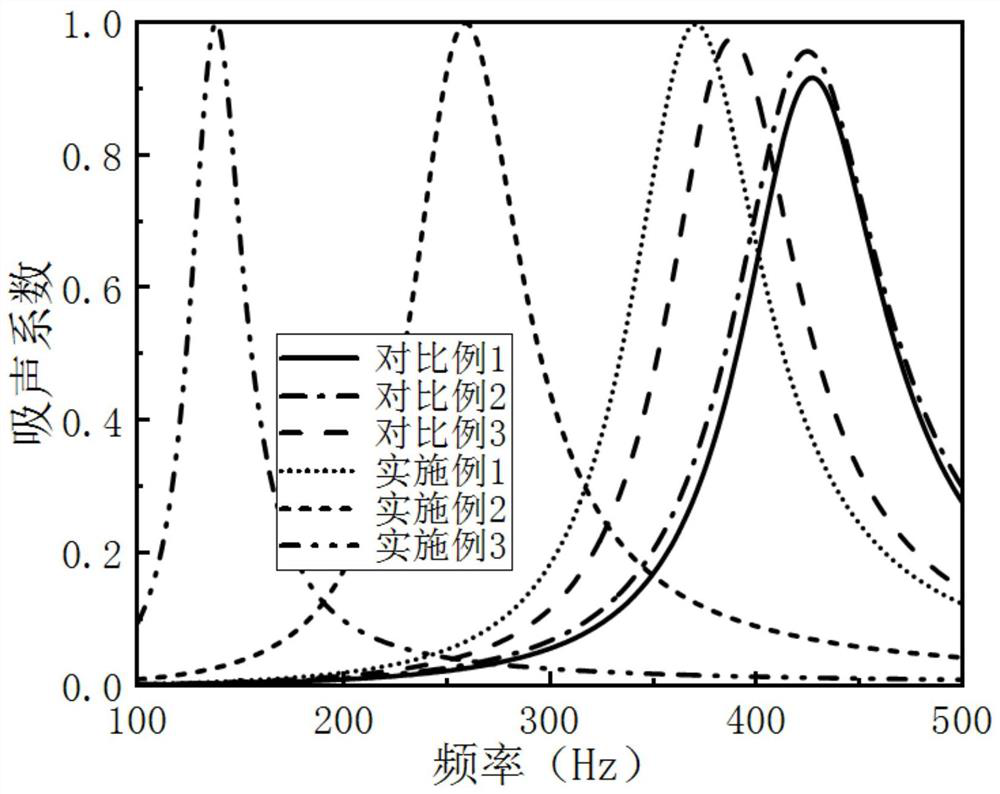

[0054] Structural dimensions and material selection of comparative examples:

Embodiment 1

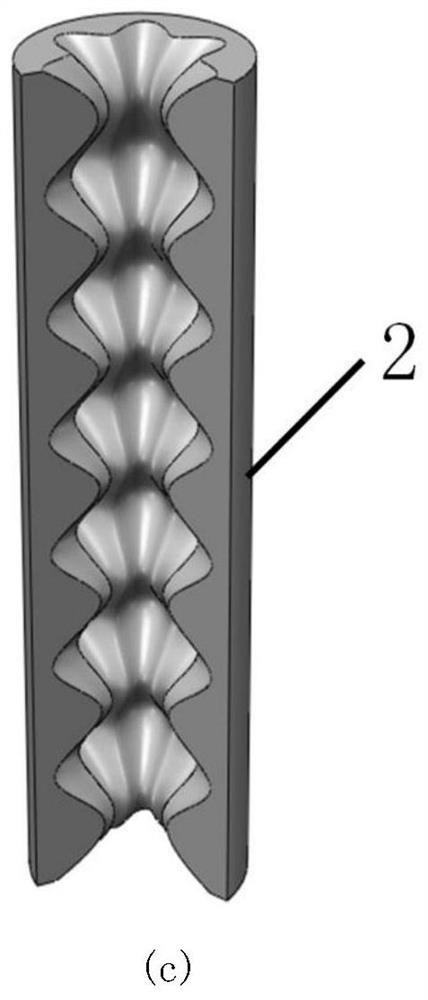

[0063] The diameter of the cavity is 20mm, the height of the cavity is 20mm, the average inner radius of the two-way rough inner tube is 1.5mm, the axial relative roughness of the two-way rough inner tube is 0.15, the axial wave number of the two-way rough inner tube is 0.5π, and the circumference of the two-way rough inner tube is The relative roughness is 0.1, the circumferential wave number of the two-way rough inner tube is 8, and the length of the two-way rough inner tube is 15mm.

Embodiment 2

[0065] The diameter of the cavity is 24mm, the height of the cavity is 30mm, the average inner radius of the two-way rough inner cannula is 2mm, the axial relative roughness of the two-way rough inner cannula is 0.25, the axial wave number of the two-way rough inner cannula is π, and the circumferential direction of the two-way rough inner cannula is relative The roughness is 0.15, the circumferential wave number of the two-way rough inner tube is 3, and the length of the two-way rough inner tube is 20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com