Automatic coring device and method for red jujubes

A nuclear device and jujube technology, applied in fruit pitting devices, food science, applications, etc., can solve problems such as low efficiency, poor labor safety, and easy injury of hands holding jujubes, so as to improve the efficiency of pitting and the amount of pitting High, effect of reducing the workload of denucleating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

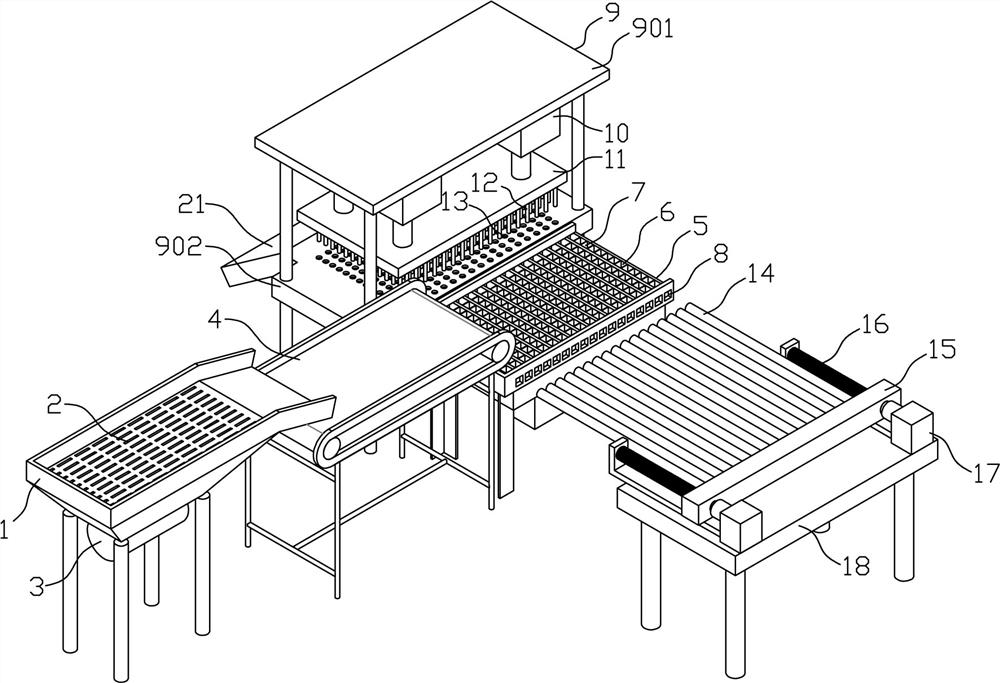

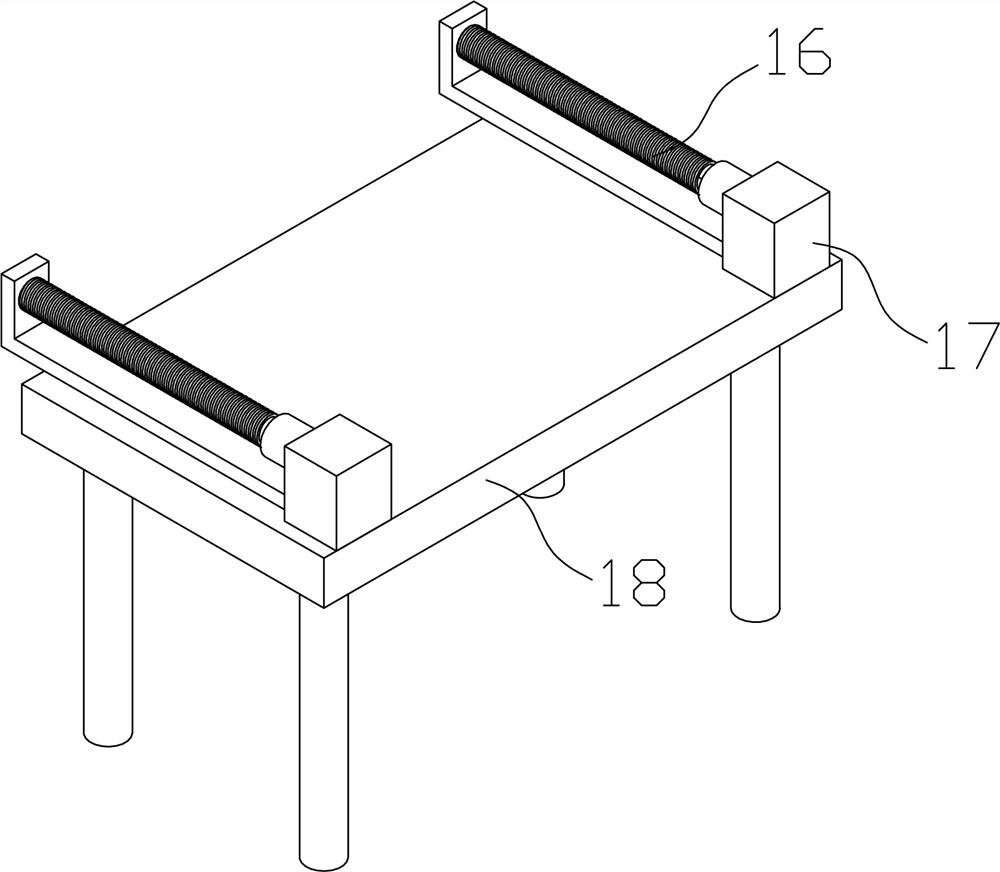

[0036] like Figure 1-5 Among them, an automatic red date pitting device, comprising a screening machine 1, a conveyor belt 4, characterized in that: it also includes a jujube row mechanism 5, a pitting mechanism 9 and a pushing mechanism 18, and the output end of the screening machine 1 is located at the conveyor belt 4 above the input end, the output end of the conveyor belt 4 is located above one end of the jujube row mechanism 5;

[0037] Described row date mechanism 5 one side is provided with denucleating mechanism 9, and the other side is provided with pushing mechanism 18;

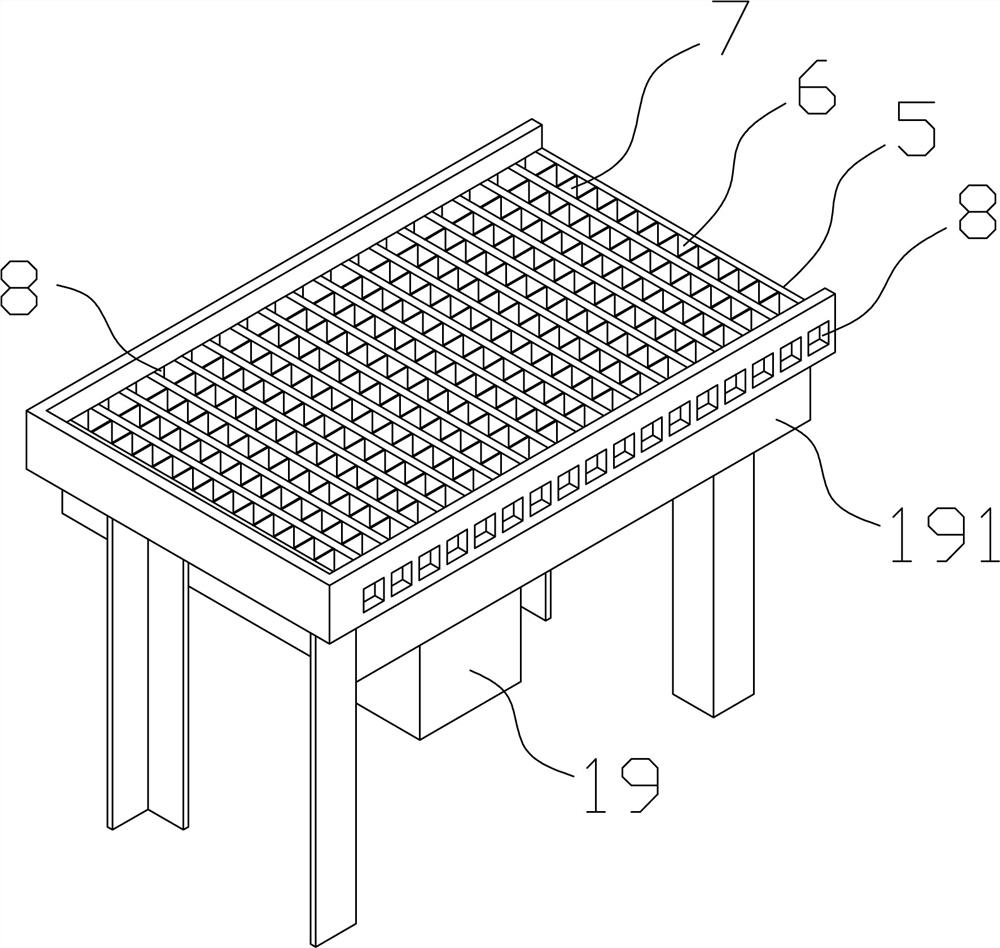

[0038] The date row mechanism 5 includes a plate with a plurality of strip grooves 6, the plate is supported by angle steel, the two ends of the strip groove 6 are provided with first through holes 8 extending to the side walls of both sides of the plate, A second push cylinder 19 is provided below the plate, and the push rod of the second push cylinder 19 faces upwards and is provided with a seco...

Embodiment 2

[0046] On the basis of embodiment 1, red jujube automatic pitting device adopts following method to carry out pitting operation:

[0047] 1) Transport the jujube to be pitted to the screening machine 1, and start the vibration motor 3 to screen out the debris and impurities mixed in the jujube;

[0048] 2) The jujube gradually moves to the conveyor belt 4 during the vibration process, falls on the conveyor belt 4 and is transported to the jujube row mechanism 5 through the conveyor belt 4;

[0049] 3) Start the vibration motor on the jujube row mechanism 5, and the red dates falling on the jujube row mechanism 5 will fall into the multiple compartments formed by the partitions 7 in the strip groove 6 one by one, and the redundant red dates will be fed by the jujube row mechanism 5. Output and collect away from the side of conveyor belt 4;

[0050] 4) The second push cylinder 19 moves, so that the second lifting plate 191 drives the spacer 7 to move down until the spacer 7 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com