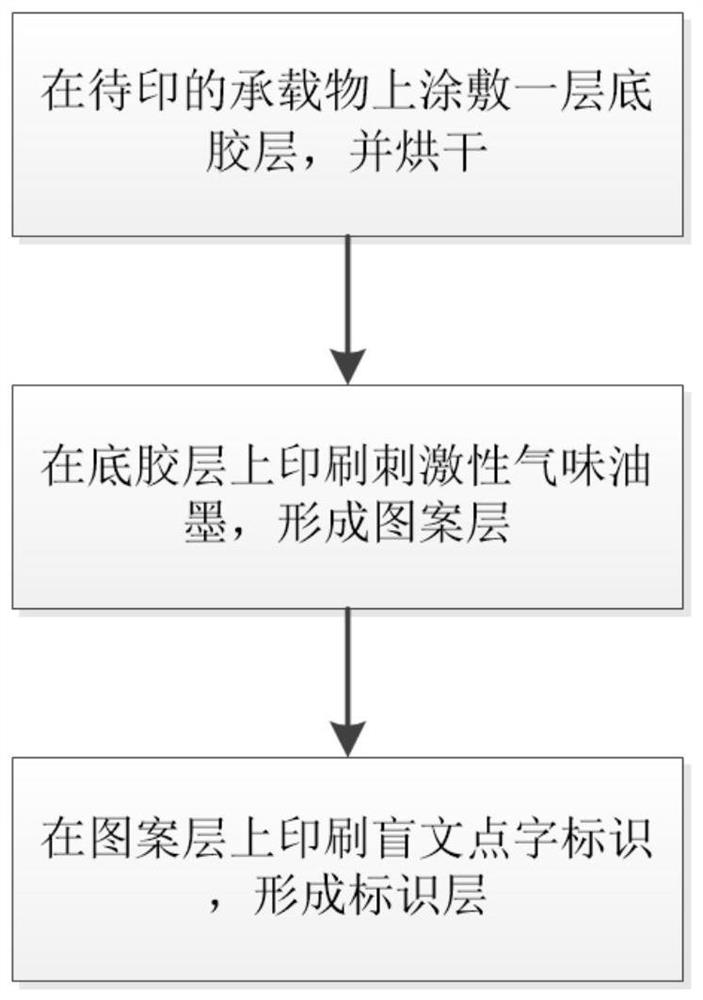

Anti-counterfeit printing method

A technology of anti-counterfeiting printing and irritating odor, applied in printing, printing process, printing of special varieties of printed matter, etc., can solve problems such as difficulty in identification, achieve high identification degree, improve identification performance, and facilitate identification of whether the product is genuine or not. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In the case of stirring, the following components are added to the stirring tank, and the components include: 20.0wt% solvent; 35.0wt% co-solvent; 10.0% pungent smell plant essence; Mixture; 5.0wt% chemical stabilizer. After the addition was complete, the mixture was stirred for 45.0 min to obtain a pungent odor ink.

Embodiment 2

[0053] In the case of stirring, the following components are added to the stirring tank, and the components include: 70.0wt% solvent; 1.0wt% co-solvent; 5.0% pungent smell plant essence; Mixture; 5.0wt% chemical stabilizer. After the addition was complete, the mixture was stirred for 30.0 min to obtain a pungent odor ink.

Embodiment 3

[0055]In the case of stirring, the following components are added to the stirring tank, and the components include: 50.0wt% solvent; 6.0wt% co-solvent; 8.0% pungent odor vegetable essence; Mixture; 1.0wt% chemical stabilizer. After the addition was complete, the mixture was stirred for 40 min to obtain a pungent odor ink.

[0056] In order to improve its identification performance, the irritating odor ink can be prepared by the following steps, including:

[0057] 20.0-70.0wt% solvent, 1.0-35.0wt% co-solvent, 5.0%-10.0% pungent smell plant essence, 10.0-20.0wt% colorant, 9.0-20.0wt% binder, 1.0-5.0wt% chemical Stabilizer, 0.5-1.0wt% fluorescent colorant content, 0-5.0wt% auxiliary agent are added to the stirring tank;

[0058] Stir the mixture in the stirring tank for 30-45.0min to obtain the pungent odor ink.

[0059] Wherein, the auxiliary agent may include one or more combinations of preservatives, pH regulators, and surfactants.

[0060] By adding the fluorescent color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com