Back box for cobblestone laying

A technology of pebbles and back boxes, applied in the field of back boxes, can solve problems such as easy fatigue in laying and affect work efficiency, and achieve the effects of saving manpower, improving work efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

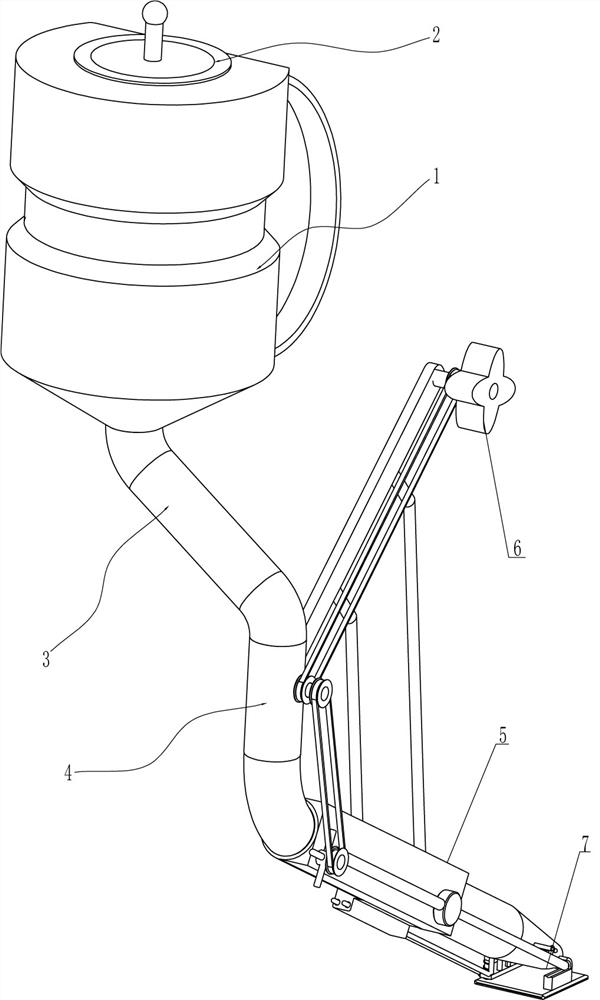

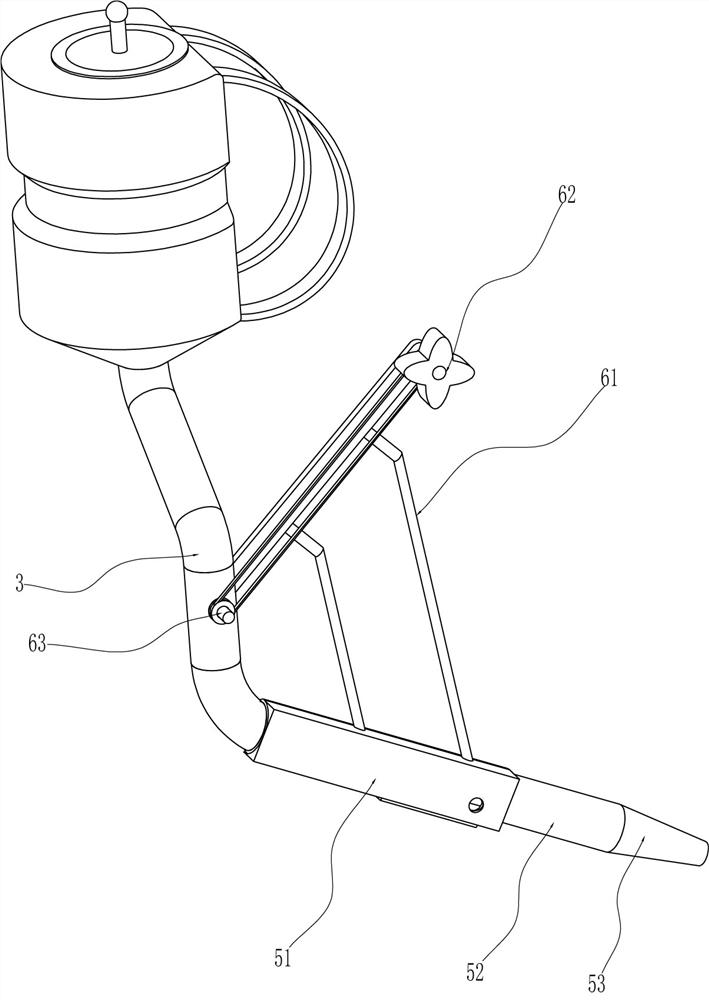

[0027] A back box for cobblestone paving, such as Figure 1-3 As shown, it includes a belt-type back box 1, a plug cover 2, a discharge pipe 3 and an extension tube 4. The top of the belt-type back box 1 is connected with a detachable plug cover 2, and the discharge end at the bottom of the belt-type back box 1 is connected to There is a feeding pipe 3, and an extension pipe 4 is connected to the end of the feeding pipe 3. The belt-type back box 1 communicates with the extension pipe 4 through the feeding pipe 3. It also includes an adjustment assembly 5 and a quantitative assembly 6. The extension pipe 4 is equipped with Regulating component 5 and quantitative component 6.

[0028] The adjustment assembly 5 includes an internally threaded pipe 51, an externally threaded pipe 52 and a lower barrel 53. The end of the extension pipe 4 is connected with an internally threaded pipe 51, and the internally threaded pipe 51 is threadedly connected with an externally threaded pipe 52....

Embodiment 2

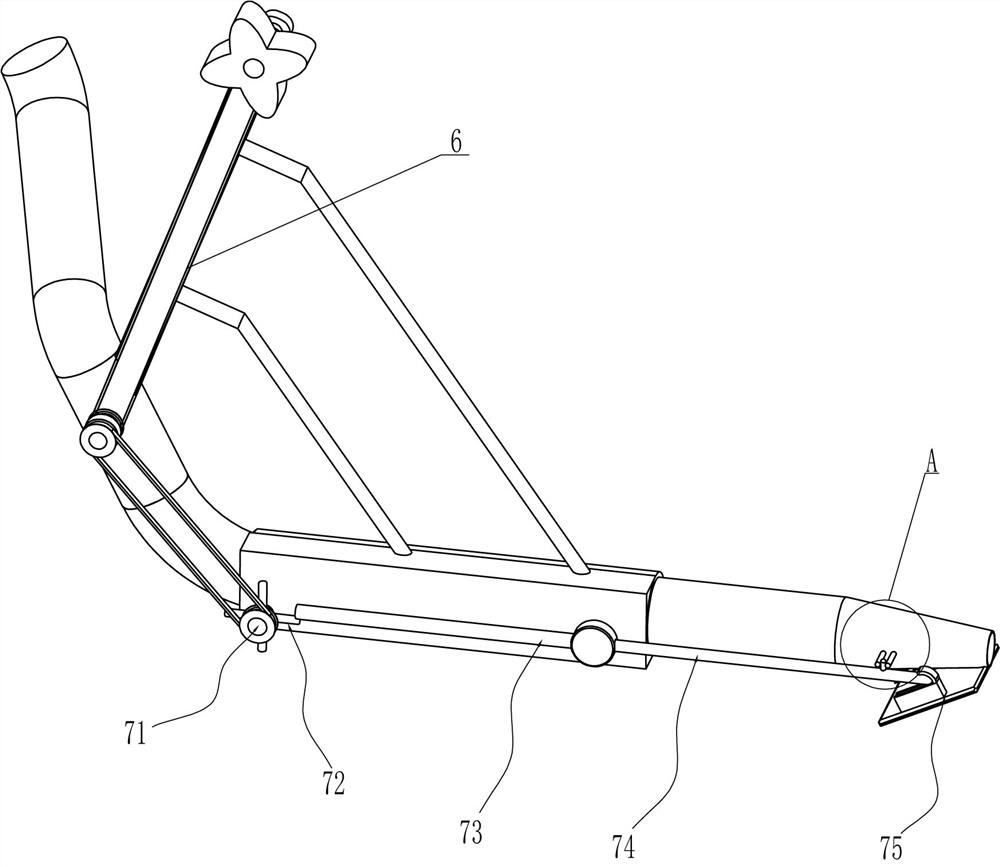

[0032] On the basis of Example 1, such as Figure 4-7 As shown, also includes a binder assembly 7, the binder assembly 7 includes a rotating shaft 71, a driving lever 72, a swing lever 73, a pressing lever 74, a pressing plate 75, a clamping lever 76, a connecting rod 77, an elastic member 78 and a torsion spring 79 , the left side of the internally threaded pipe 51 is rotationally connected with a rotating shaft 71, and the rotating shaft 71 is connected with four driving rods 72 evenly spaced in the circumferential direction. The outer right side of the pipe 51 is rotationally connected with a fork 73, and a torsion spring 79 is connected between the fork 73 and the internally threaded pipe 51. The fork 73 cooperates with the driving lever 72, and the inside of the fork 73 is slidably connected with a pressure bar 74. There is a certain resistance between the pressure rod 74 and the swing rod 73. Two clamp rods 76 are connected to the right front side of the lower barrel 53....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com