Safety fixture for edge operation and using method thereof

A fixture and safety technology, which is applied to the safety fixture for edge work and its use field, can solve problems such as hidden safety hazards, and achieve the effect of convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

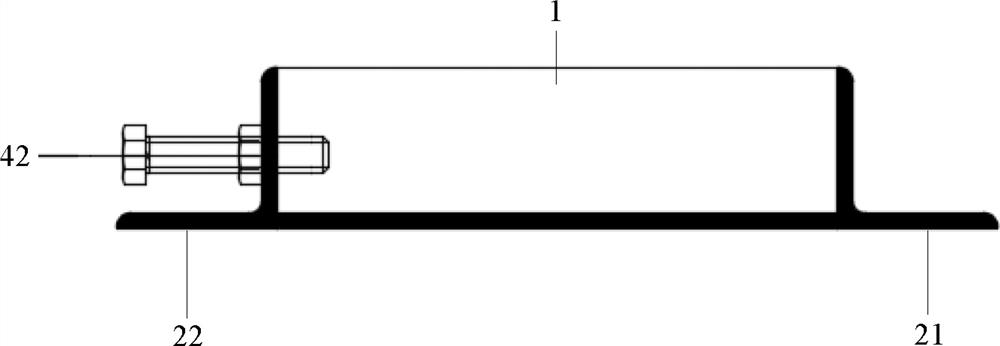

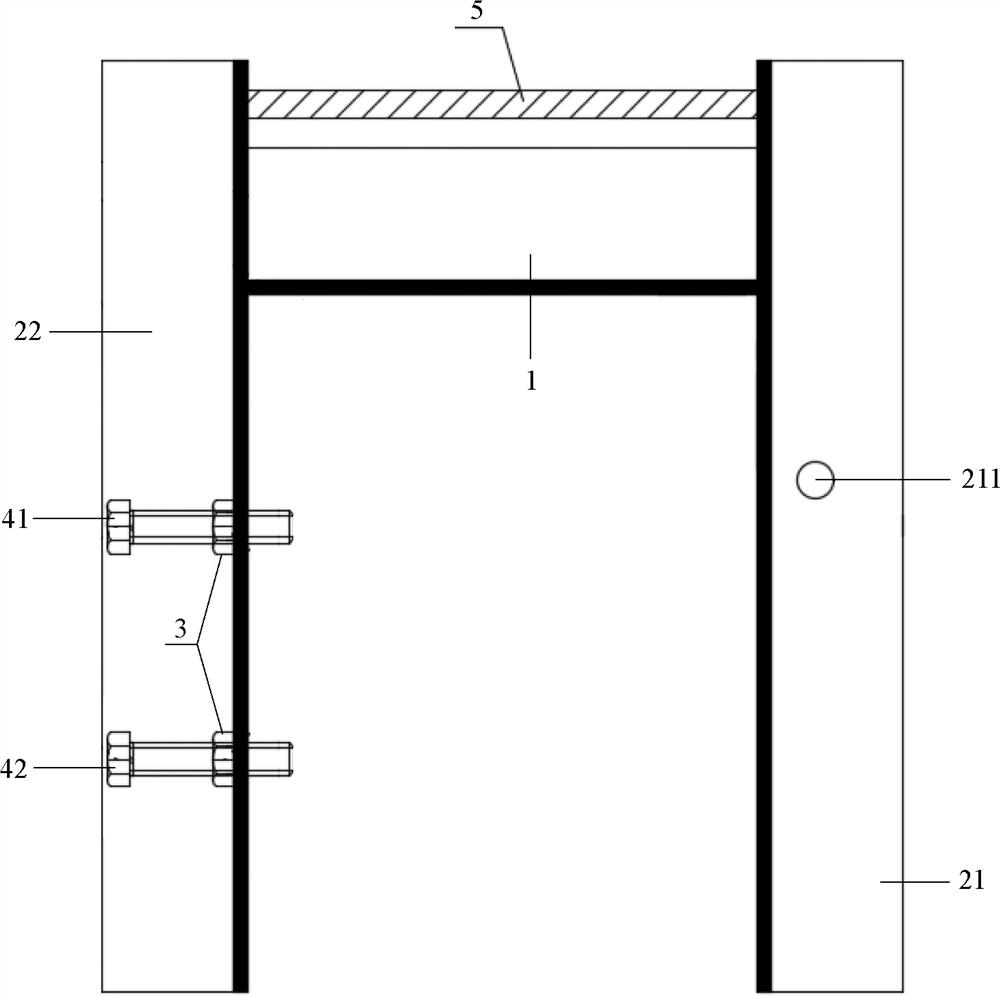

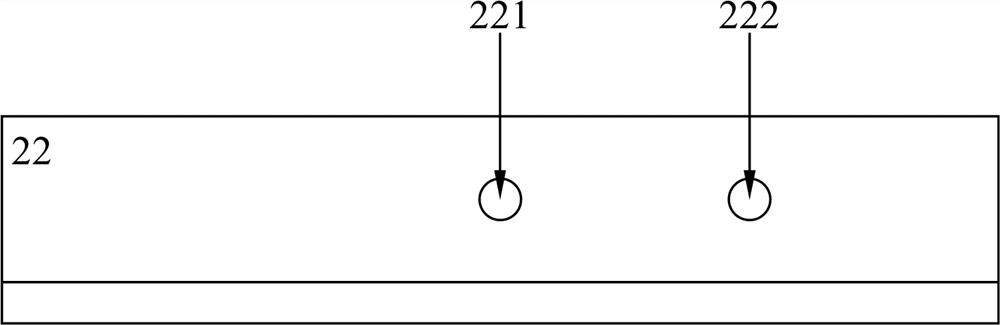

[0030] A safety fixture for edge operations, comprising a top angle steel 1, a tie angle steel 21, a fastening angle steel 22, a fastening nut 3, a front fastening bolt 41 and a rear fastening bolt 42, such as Figure 1 ~ Figure 4 As shown, the specific structure is:

[0031] The horizontal plates of the top angle steel 1, the hanging angle steel 21 and the fastening angle steel 22 are all arranged on the same plane, and the vertical plates of these three are all arranged on the same side of the horizontal plate, and the hanging angle steel 21 and the fastening angle steel 22. The two are arranged in parallel to each other with the vertical plates. The top angle steel 1 and the hanging angle steel 21 and the fastening angle steel 22 are perpendicular to each other. The two ends of the top angle steel 1 are respectively fixed on the vertical plate front and the Fasten the front part of the vertical plate of the angle steel 22;

[0032] The horizontal plate of the hanging angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com