Electrostatic spraying method for printed circuit board

A technology for printed circuit boards and electrostatic spraying, which is applied to the device, coating, spraying device and other directions of coating liquid on the surface, which can solve the problem of oil accumulation on the edge of the board, different spraying depth, and uneven width and height of the circuit board. problems, to achieve the effect of good spraying, different depths, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Due to the different sizes of each circuit board during electrostatic spraying of the existing circuit boards, if they are all modularized for processing, there are some problems, and processing defective products are prone to occur. Manual reprocessing is often required, which greatly reduces work efficiency. Therefore, an electrostatic spraying method for processing the size of the circuit board is needed to solve the problems existing in the existing spraying method.

[0023] In order to facilitate those skilled in the art to understand the technical solution more clearly, the present invention will be further described through examples below.

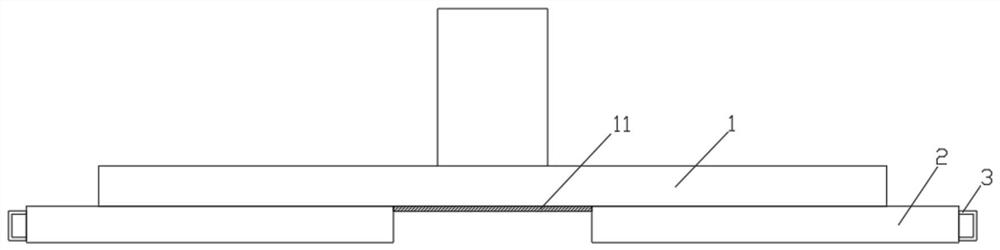

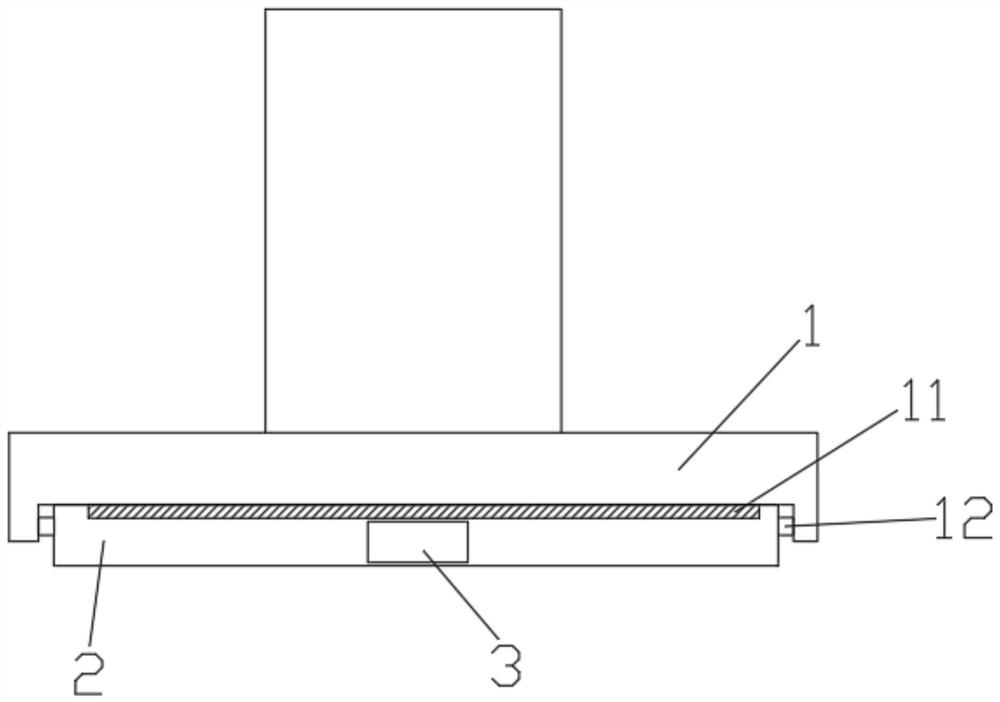

[0024] A method for electrostatic spraying of printed circuit boards in this embodiment mainly includes a product placement area, a product classification area, a detection area, and an electrostatic spraying area; wherein the product classification area is classified according to the width of the circuit board, and the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com