Automatic cleaning and ash-removing window

An automatic cleaning and window technology, applied in the field of windows, can solve the problem of difficult cleaning of sliding window chutes, and achieve the effect of avoiding exposure to the outside.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

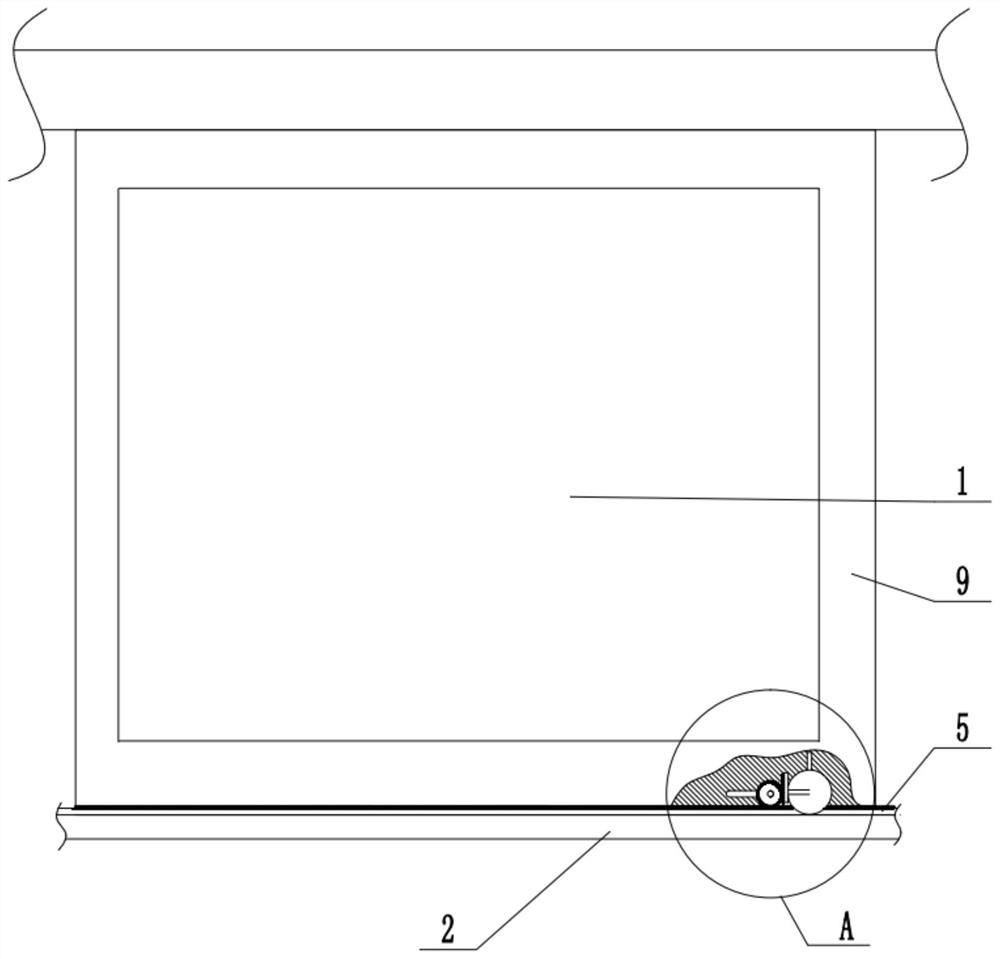

[0033] The embodiment is basically as follows: as attached figure 1 As shown, a self-cleaning and dust-removing window includes two window main bodies 1 and frames 2 . The top of the frame 2 has an upper chute group, and the bottom of the frame 2 has a lower chute group. The size and structure of the upper chute group and the lower chute group are the same.

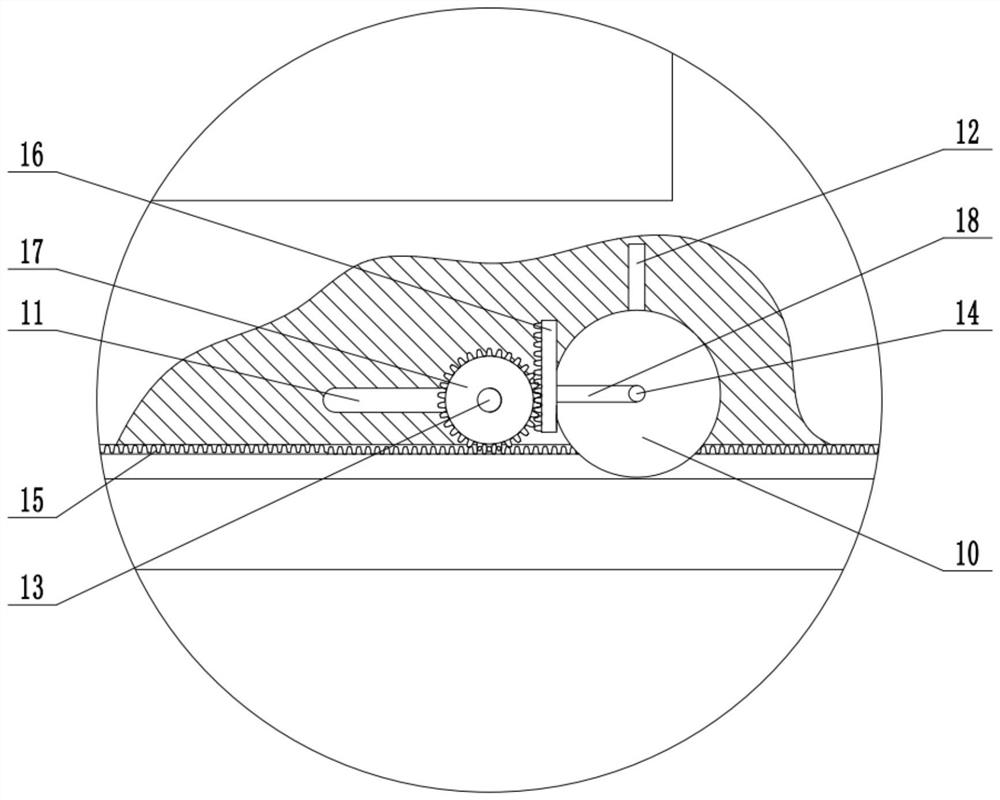

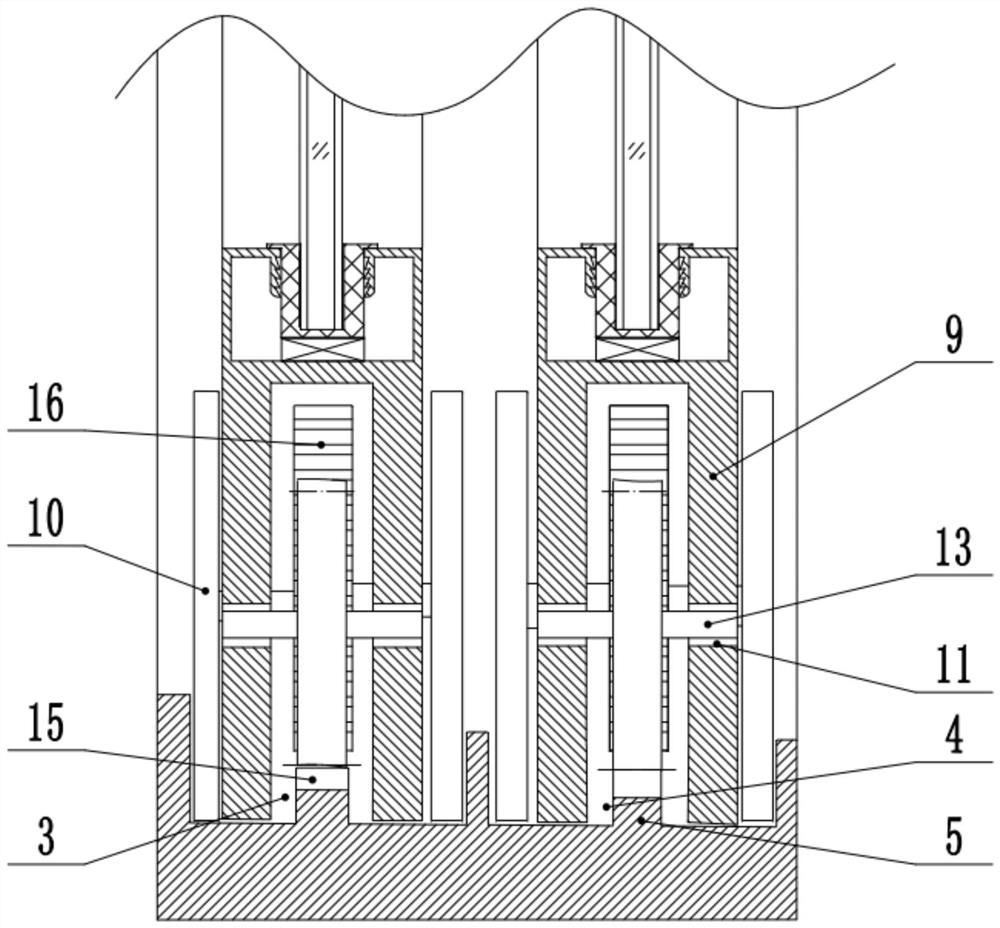

[0034] as attached image 3 As shown, the chute group includes two parallel first chute 3 and second chute 4, the bottom surfaces of the first chute 3 and the second chute 4 are integrally formed with support slide rails 5 respectively, and the support slide rails 5 is integrally formed with the first chute 3 and the second chute 4, and the supporting slide rail 5 and the sliding chute group are parallel to each other.

[0035] The two window main bodies 1 are slidably connected to the first sliding groove 3 and the second sliding groove 4 respectively. The window body 1 includes a rectangular frame 9 , the frame 9 is...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that, as Figure 4As shown, there are collection holes 6 on the left bottom surfaces of the first chute 3 and the second chute 4 respectively, and a cavity 7 is opened directly below the first chute 3 and the second chute 4, and the two collection holes The holes 6 are all in communication with the cavity 7 . The side wall of the cavity 7 is connected to the outside, and the cavity 7 is horizontally slidably connected with a dust collection drawer 8 at the connection point of the side wall.

[0043] The specific implementation process: finally when the window main body 1 moves to the right end of the frame 2, the dust concentrated on the right side of the cleaning wheel 10 will fall into the collection hole 6, and the dust will fall into the dust collection drawer 8 through the collection hole 6. When the accumulation reaches a certain level, the operator only needs to extract the dust collection drawer 8 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com