I type stress intensity factor test method considering frost heaving force periodic change

A technology of stress intensity factor and periodic variation, applied in the field of civil engineering, can solve the problem of inaccurate results and achieve the effect of accurate characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following technical solutions in the present invention are clearly and completely described. Obviously, the described embodiments are some embodiments of the present invention, rather than all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

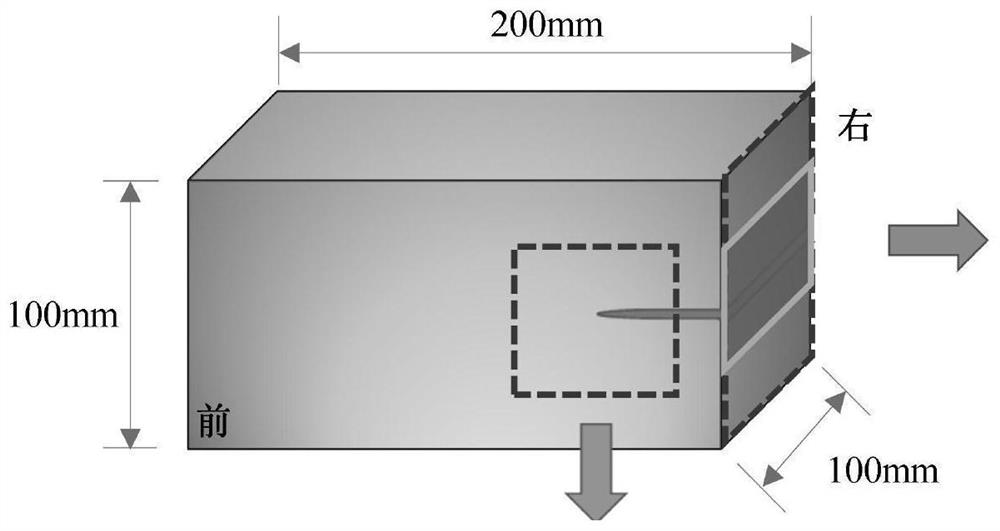

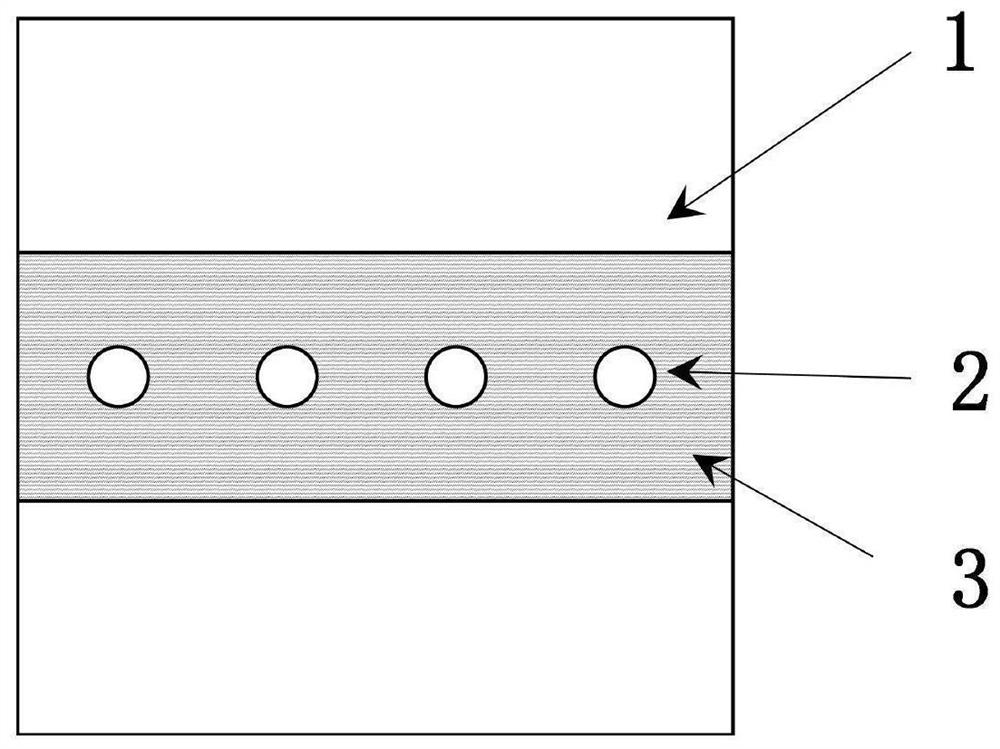

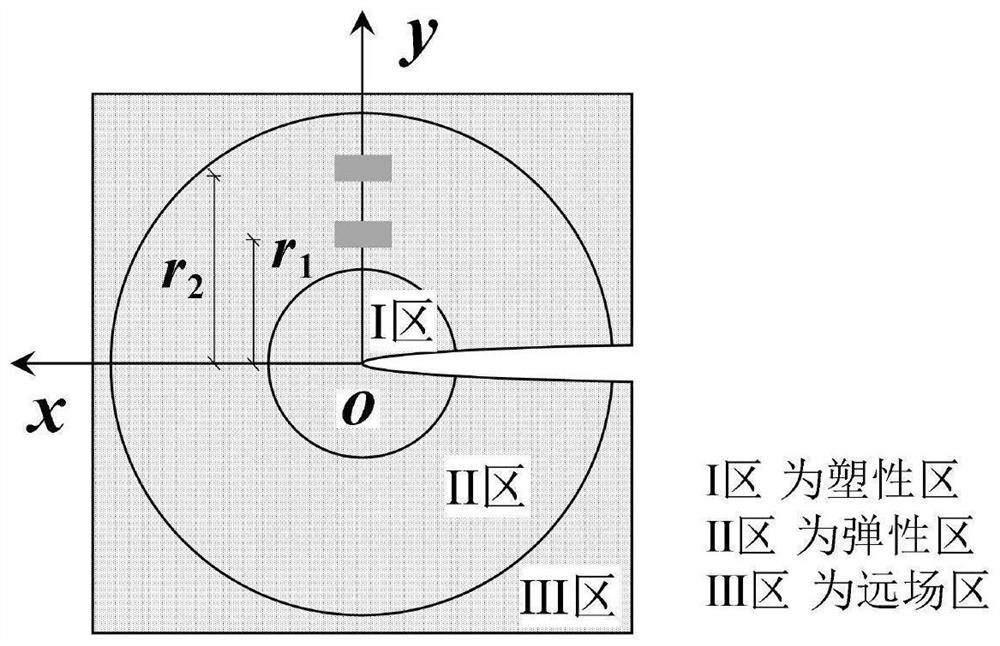

[0026] Such as Figure 1-3 As shown in Fig. 1, a specimen with a size of 200mm×100mm×100mm (length×width×height) is made, and the cracks are opened due to the action of frost heaving force, and the cracks can be approximated by cutting with a water knife, see figure 1 shown. The specimen is evacuated and saturated, and the plastic zone radius r is determined by numerical simulation p (Zone I); the pasting distances within the range of Zone II on the y-axis are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap