Low-noise electromagnetic relay

An electromagnetic relay, low-noise technology, applied in the direction of electromagnetic relay, electromagnetic relay details, relays, etc., can solve the problems of slow armature action, heavier armature of movable parts, and non-working relay, so as to eliminate the noise of collision yoke, Reduce working noise and eliminate the effect of releasing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

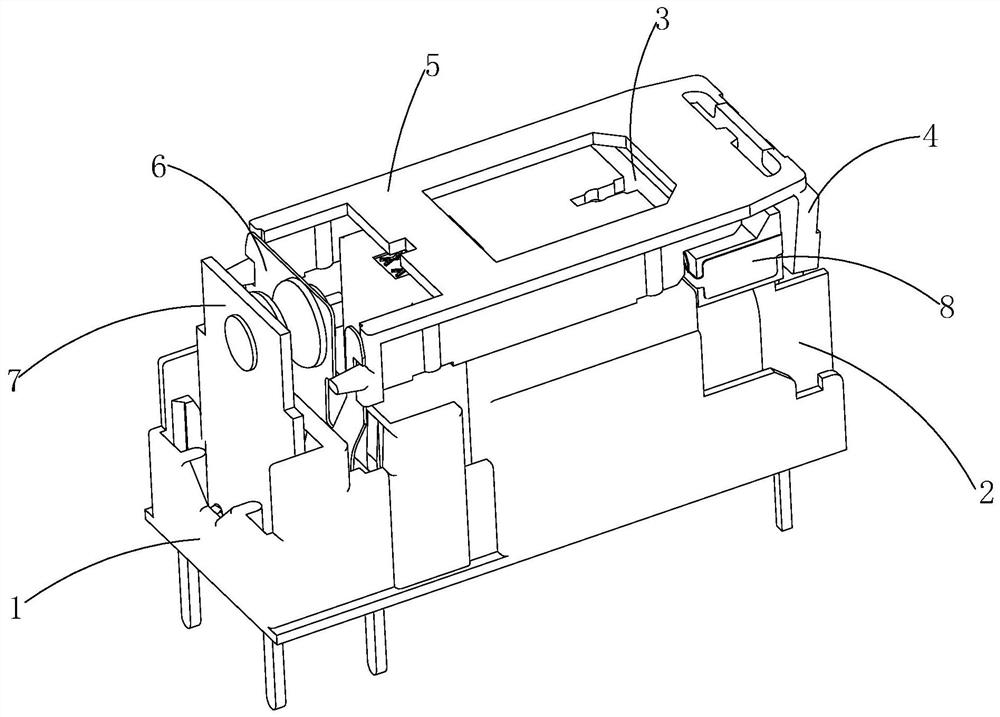

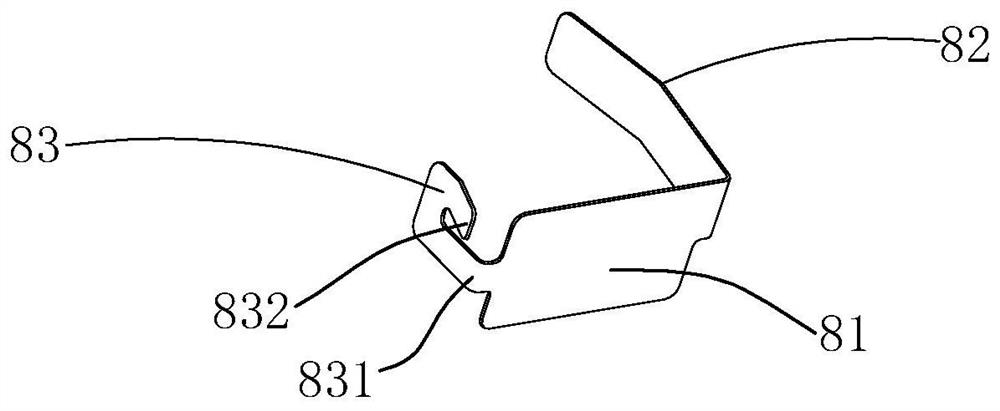

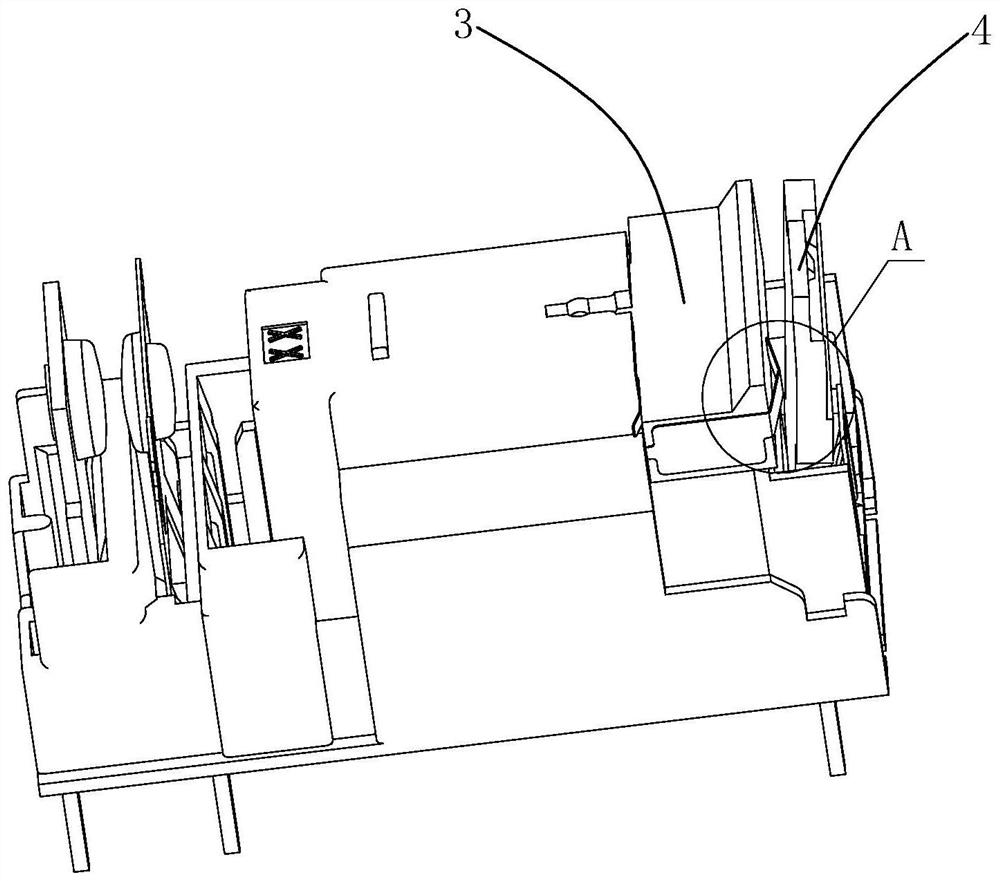

[0031] Examples, see Figure 1-Figure 8 As shown, a low-noise electromagnetic relay of the present invention includes a base 1, a magnetic circuit part, and a contact part. The magnetic circuit part includes a horizontal coil unit 2, and a yoke 3 and an armature that cooperate with the coil unit 2. 4. The armature 4 is connected with the moving spring 6 of the contact part by pushing the card 5, and when the armature 4 is closed, it swings toward the pole surface provided at one end of the yoke 3. The present invention also includes a sound-absorbing sheet 8, the sound-absorbing sheet 8 adopts a magnetically permeable material, and the sound-absorbing sheet 8 includes a fixed part, a first elastic buffer structure connected to the fixed part, and a second elastic buffer structure connected to the fixed part , the fixed part is fixed on the yoke 3, the first elastic buffer structure fits between the pole surface of the yoke 3 and the armature 4, and the second elastic buffer st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com