A-type lifting lug trimming device and using method thereof

A technology of hanging horses and hanging holes, which is applied to sawing machine devices, attachments of sawing machines, metal sawing equipment, etc., can solve problems such as low efficiency, affecting the quality of trimming, and hidden safety hazards, so as to reduce labor intensity and trimming efficiency. High, improve the effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

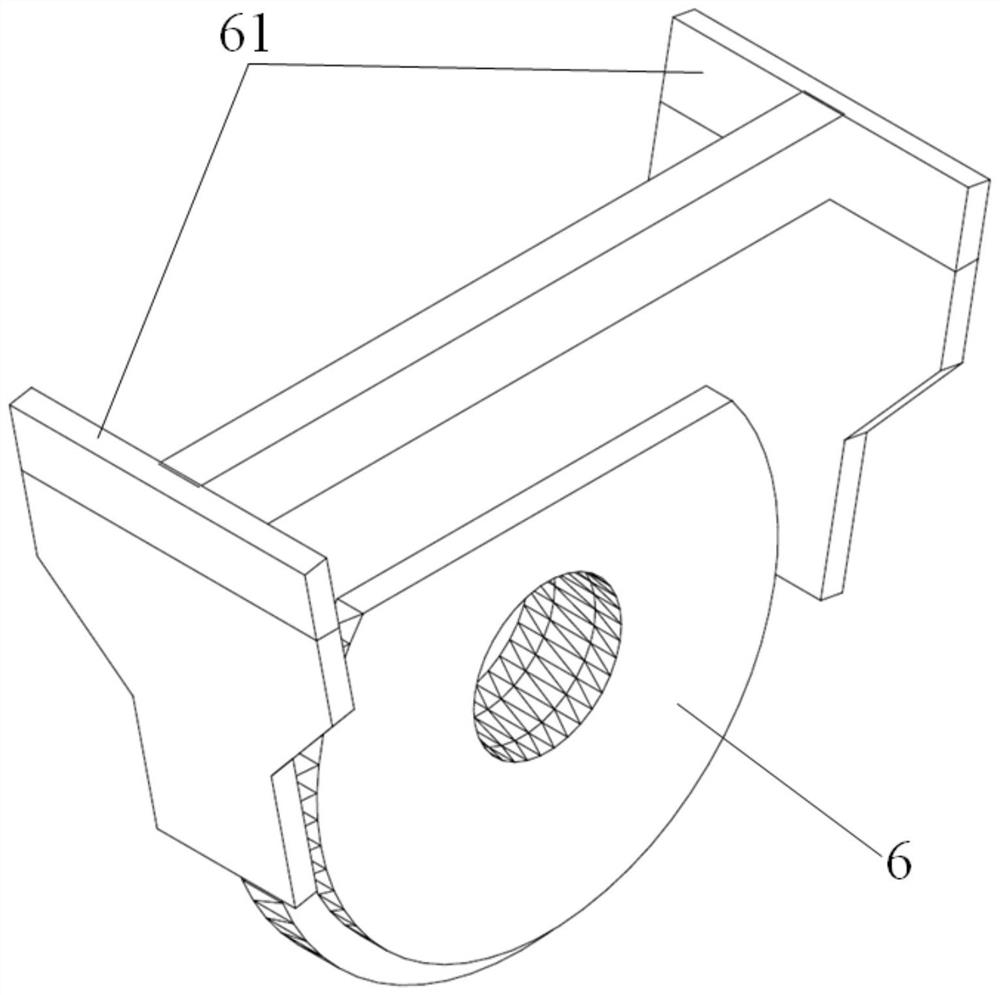

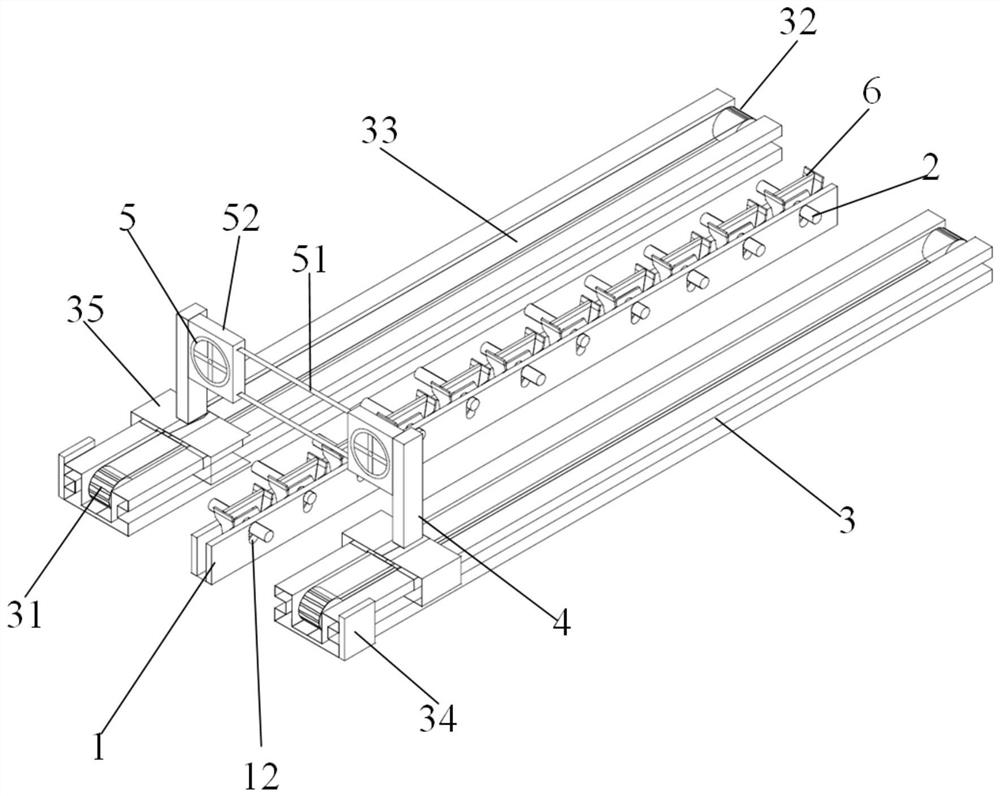

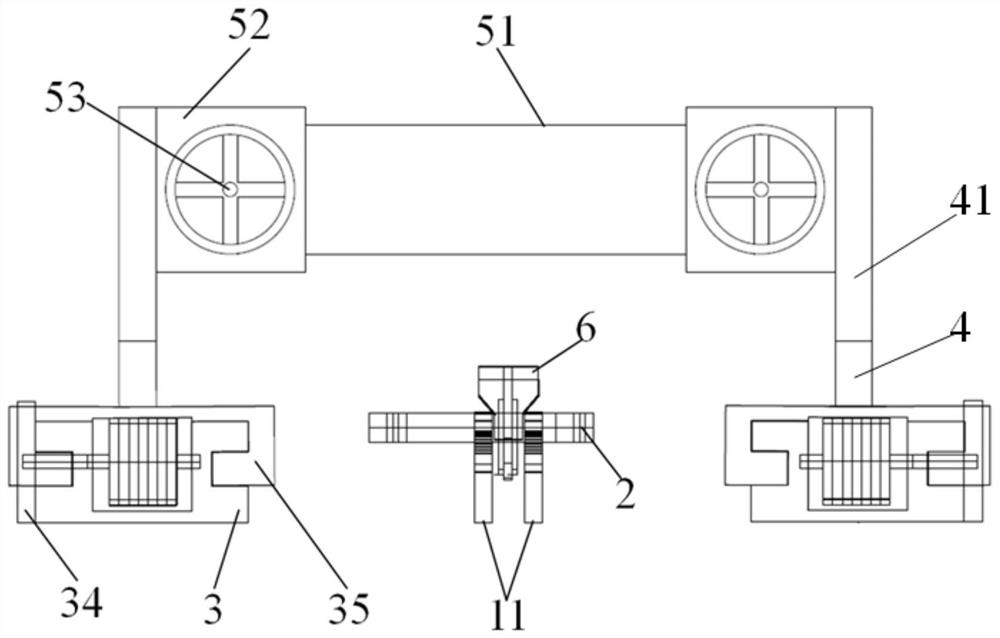

[0037] Such as Figure 1 to Figure 7As shown, a kind of A-type hanging horse repairing and cutting device of the present invention is used for repairing and cutting the welding surface of A-type hanging horse 6. 1 includes two vertical support plates 11 arranged in parallel, and a gap for clamping the A-type hoisting horse 6 is provided between the two support plates 11, and the gap between the two support plates 11 is larger than the A-type to be trimmed. The length of the bottom of the type hanging horse ear plate 61, and less than the upper length of the A type hanging horse ear plate 61 to be trimmed (that is, less than the width of the welding surface of the A type hanging horse of the minimum specification to be trimmed), in this implementation In the example, the length direction of the A-type hoisting ear plate 61 is a direction parallel to the center line of the A-type hoisting 6 hoisting holes; two support plates 11 are also relatively provided with several positioni...

Embodiment 2

[0039] Such as Figure 1 to Figure 8 As shown, a kind of A-type hanging horse repairing and cutting device of the present invention is used for repairing and cutting the welding surface of A-type hanging horse 6. 1 includes two vertical supporting plates 11 arranged in parallel, and a gap for clamping the A-type hoisting horse 6 is provided between the two supporting plates 11, and the gap between the two supporting plates 11 is larger than the largest The length of the lower part of the A-type hanging horse ear plate 61 of the specification, and the upper length of the A-type hanging horse ear plate 61 of the minimum specification to be trimmed (that is, less than the welding surface of the A-type hanging horse of the minimum specification to be trimmed) Width), in the present embodiment, the length direction of the A-type hanging horse ear plate 61 is a direction parallel to the center line of the A-type hanging horse 6 lifting holes; two support plates 11 are also relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com