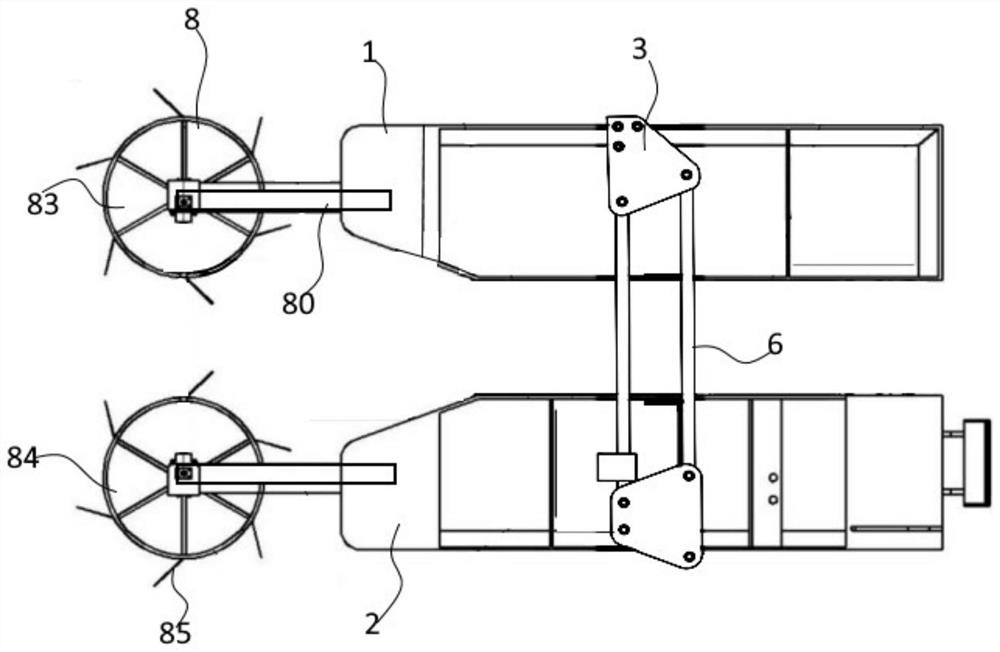

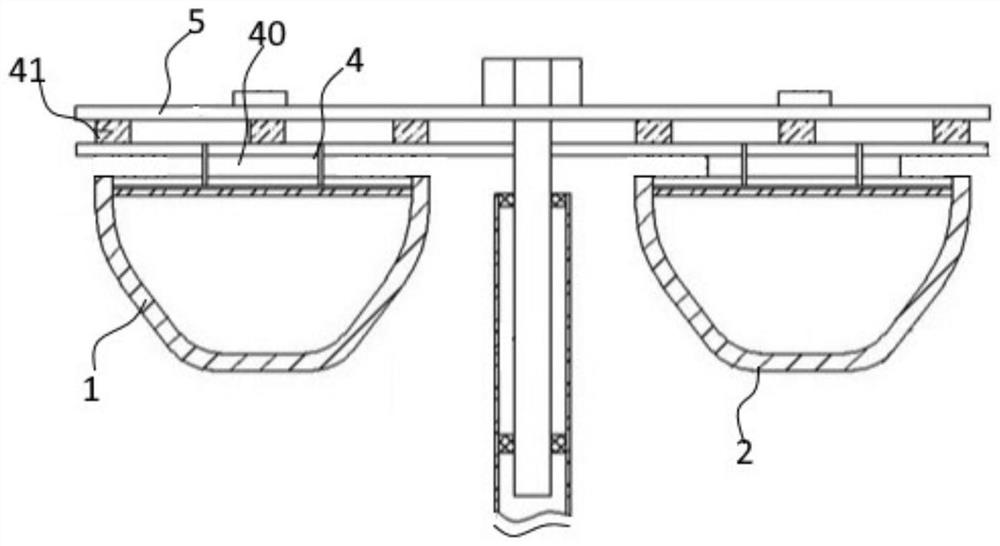

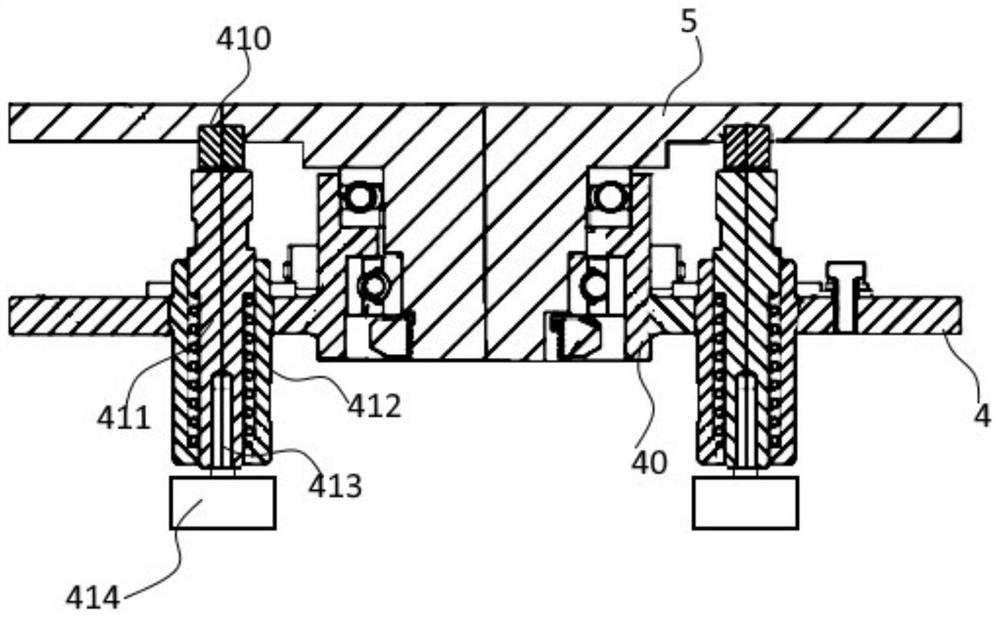

Overwater drilling ship and working method

A technology for drilling ships and hulls, which is applied to water drilling ships and working fields, can solve the problems of difficult access to drilling platforms, clogging of drilling rigs, different widths and narrow waters of inland rivers, etc., and achieves good stability and good wind and wave protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0029] The applicant found that during the drilling process of inland rivers, the drilling ship is facing more frequent problems than offshore drilling, and the traditional river-sea drilling platform cannot be used in the drilling process of shallow rivers. First, the inland rivers are not as wide as rivers and seas. The inland rivers have different widths and narrow waters, which makes it difficult for some drilling platforms with a single width and large draft to enter or cannot be adjusted according to the terrain. Secondly, there are a lot of garbage and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com