Engine blade intake and exhaust edge profile measuring device and measuring method

A technology for engine blades, intake and exhaust edges, applied to measuring devices, instruments, etc., can solve problems such as difficulty in data acquisition, difficulty in extracting data from engine blade intake and exhaust edge processing contours, etc., achieve high measurement accuracy, avoid measurement errors, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] first part:

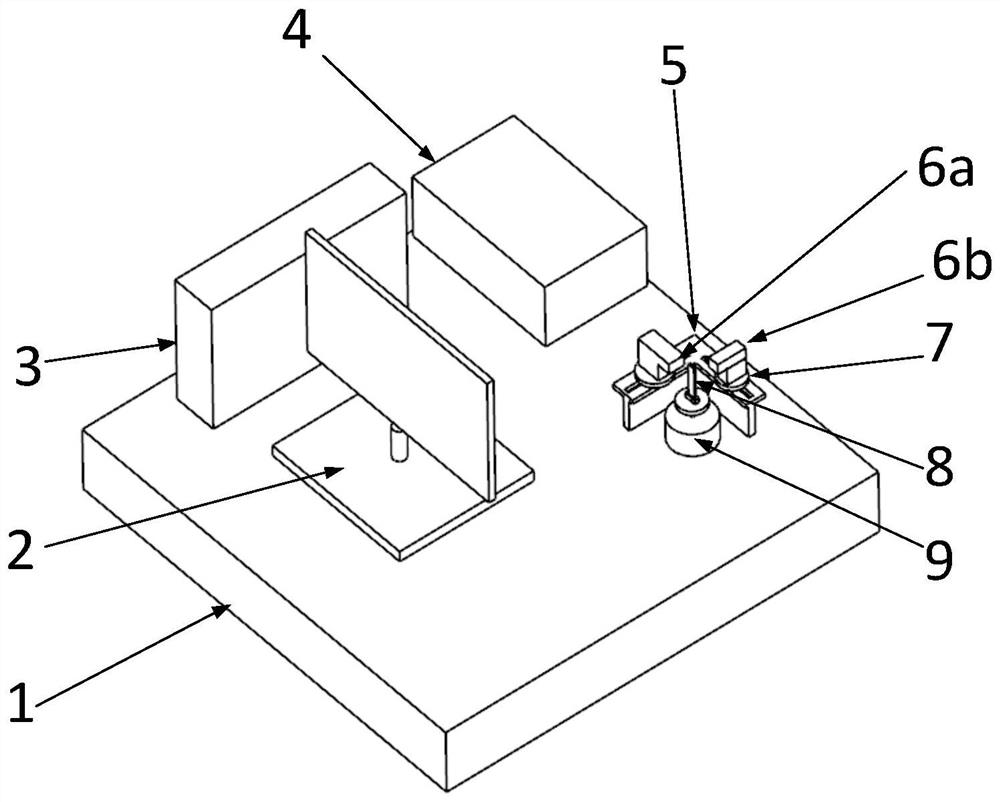

[0030] Attached below figure 1 to attach Figure 5 The present invention will be described in detail.

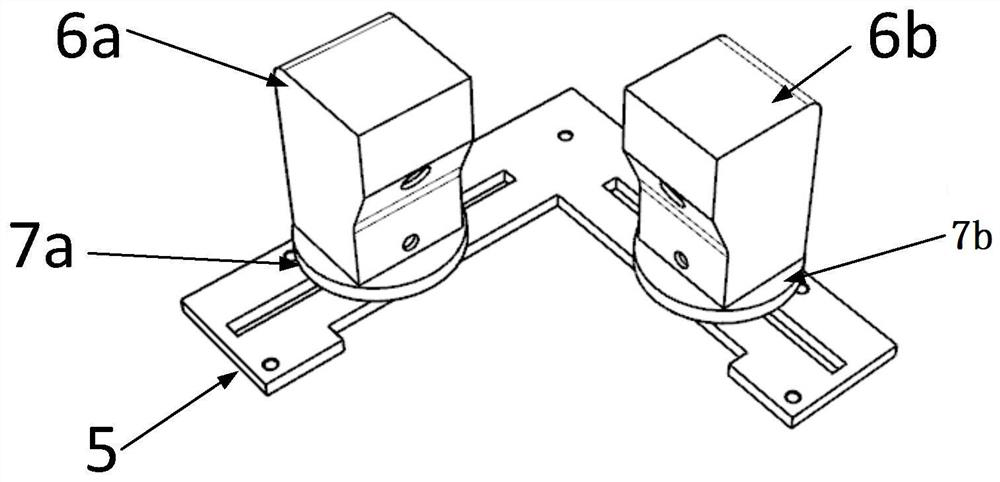

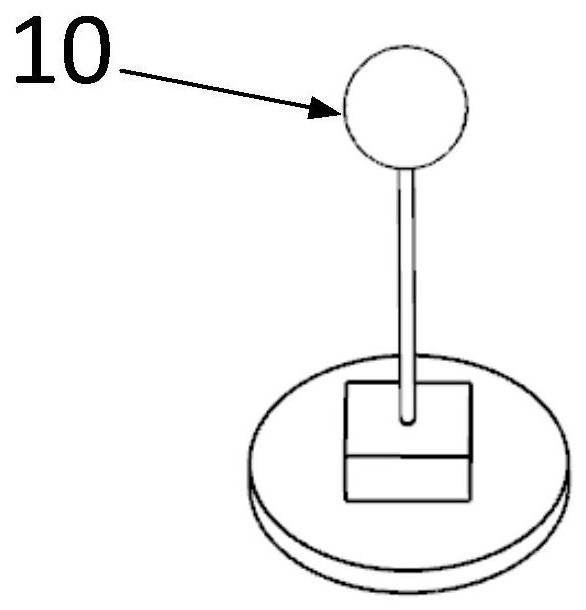

[0031] 1. The present invention provides a kind of measuring device based on dual-sensor engine blade intake and exhaust edge profile ( Figure 1-3 ), the measuring device includes a high-precision measuring platform (1), a computer monitor (2), a host computer (3), a motion control card (4), a sensor positioning platform (5), a non-contact sensor (6), a sensor angle It consists of a regulating disc (7), an engine blade (8), a high-precision electric lifting platform (9), and a calibration ball (10).

[0032] Among them, the sensor positioning device (5) and the high-precision electric lifting platform (9) are fixed on the air floating platform or the marble bearing platform (1), and the bearing platform is required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com