Actuator for mounting on injection molding machine, actuator cooling device, injection molding machine, and method for using actuator cooling device

A technology of injection molding machine and cooling device, which is applied in the directions of electromechanical devices, electric components, casings/covers/supports, etc., can solve the problems of insufficient cooling of AC servo motors and increased thermal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0046] (driver)

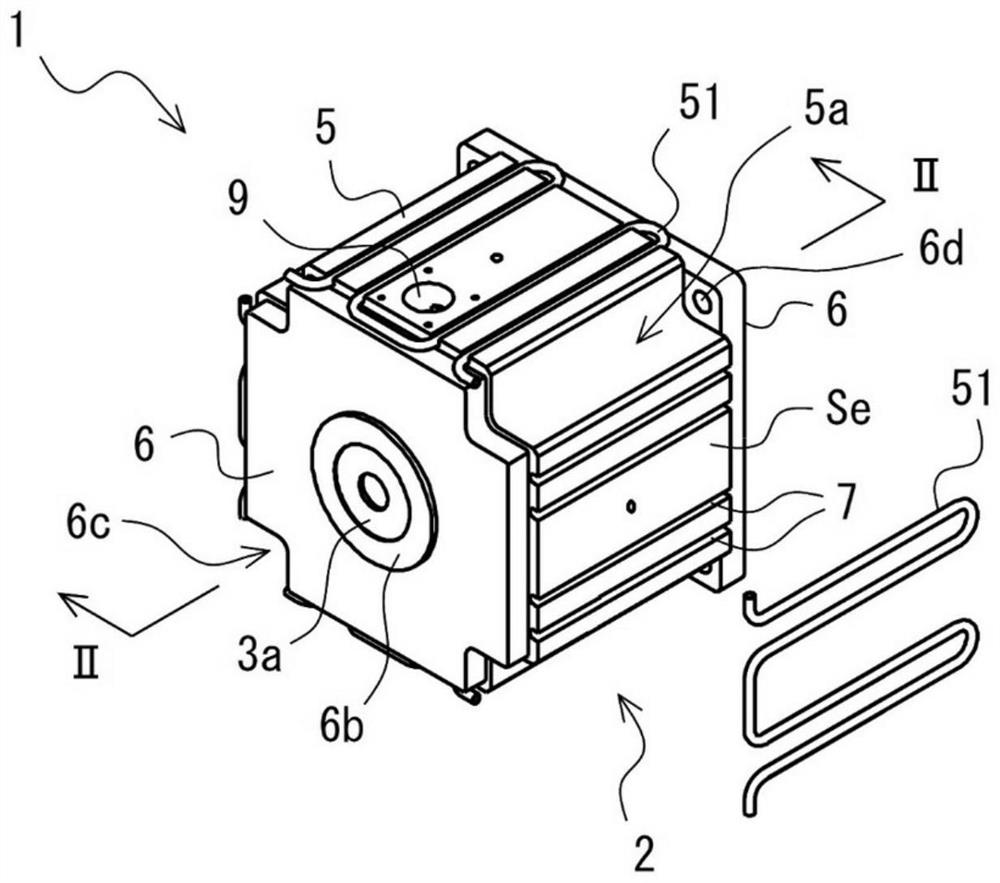

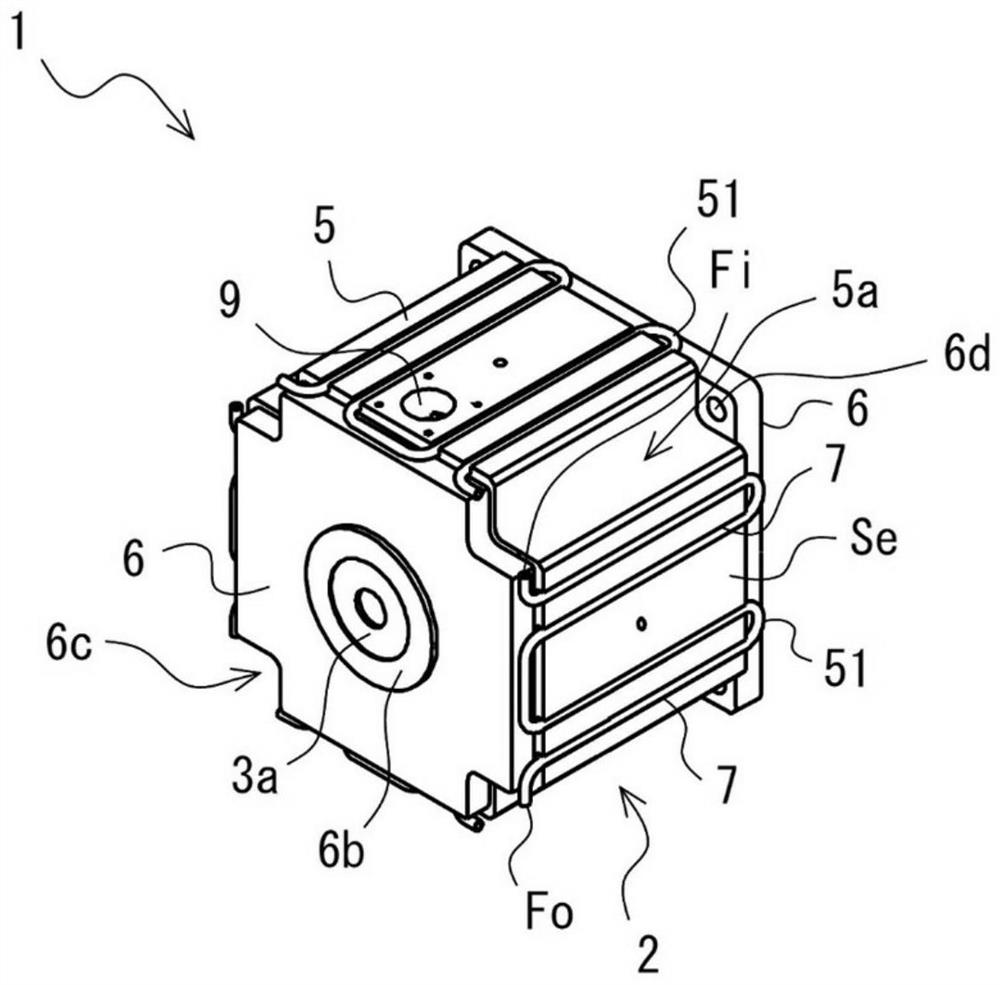

[0047] Such as figure 1 As shown, 1 in the figure shows the driver mounted on the injection molding machine, and 2 in the figure shows the driver case constituting the exterior of the driver 1 .

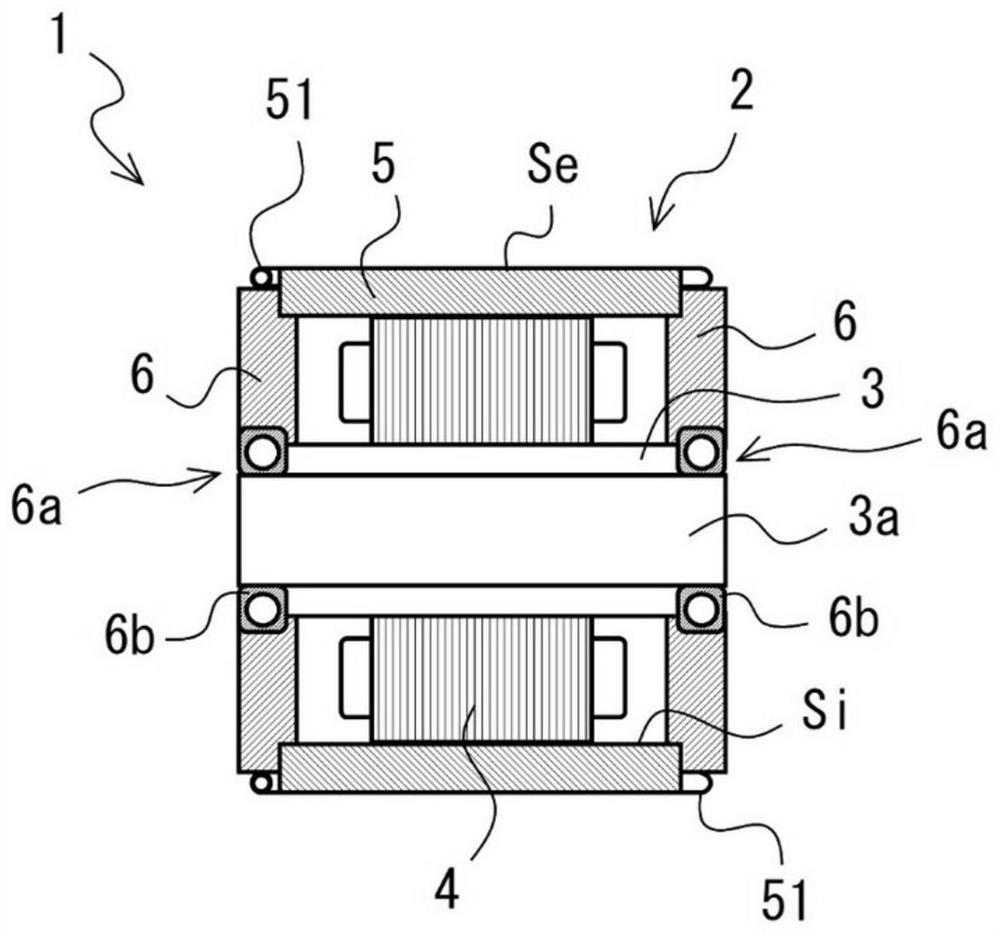

[0048] The illustrated driver 1 is taken as an example, such as figure 2As shown in the longitudinal sectional view along the direction of the rotation axis, an AC servomotor or other electric motors are provided. The AC servomotor includes an output shaft 3a, a rotor 3 as a rotor disposed around the output shaft 3a, and a rotor disposed on the rotor. A stator 4 as a fixing member for the coil on the outer peripheral side of 3, and a stator frame 5 on which the stator 4 is mounted and provided on the inner surface Si.

[0049] The driver housing 2 is a frame body including a cylindrical stator frame 5 whose cross-sectional inner and outer contou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap