Automobile hallstand detection tool

A technology for detecting tooling and coat racks, applied in measuring devices, instruments, etc., can solve the problems of cumbersome detection procedures, inaccurate detection, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

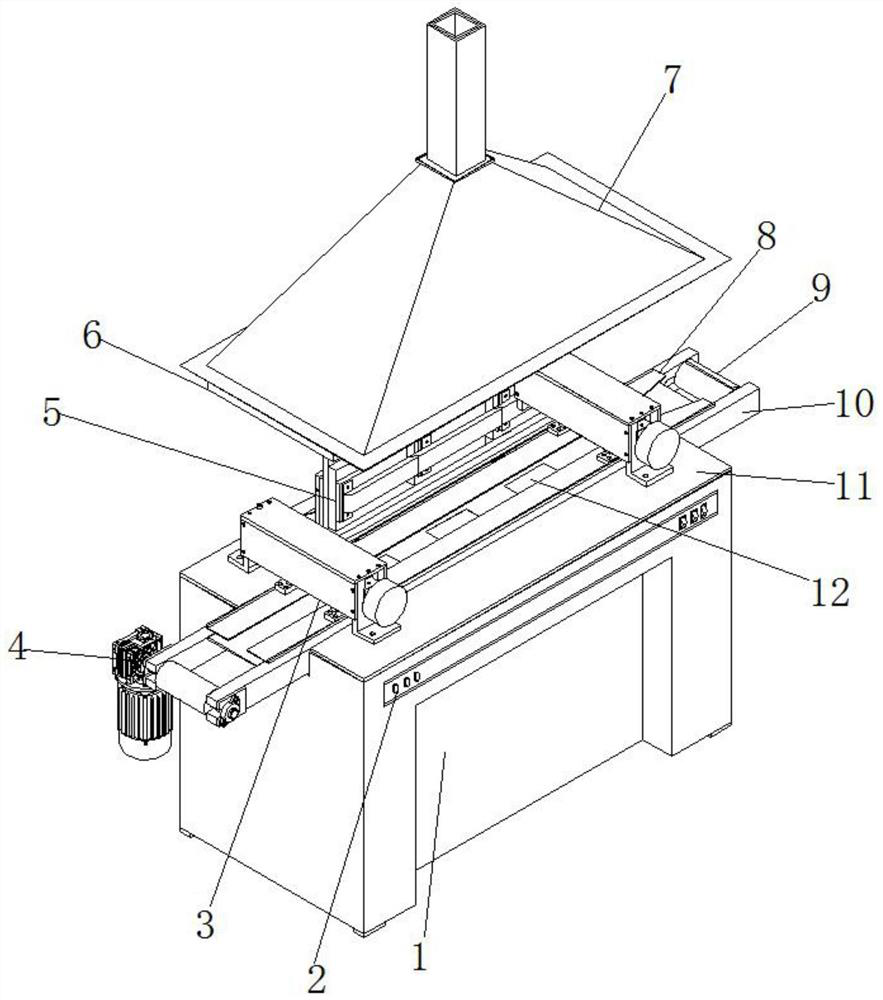

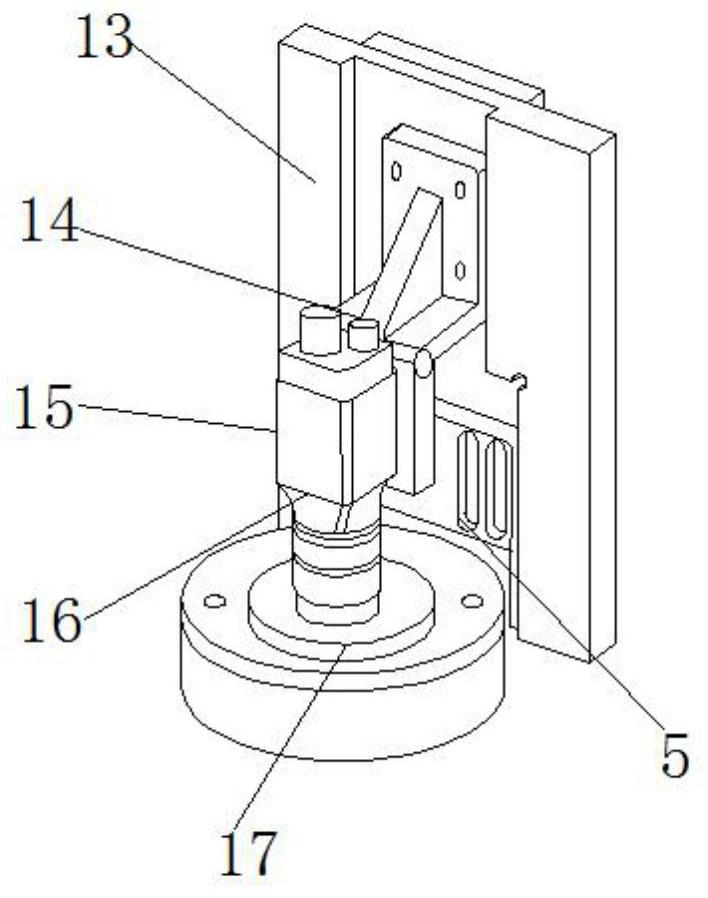

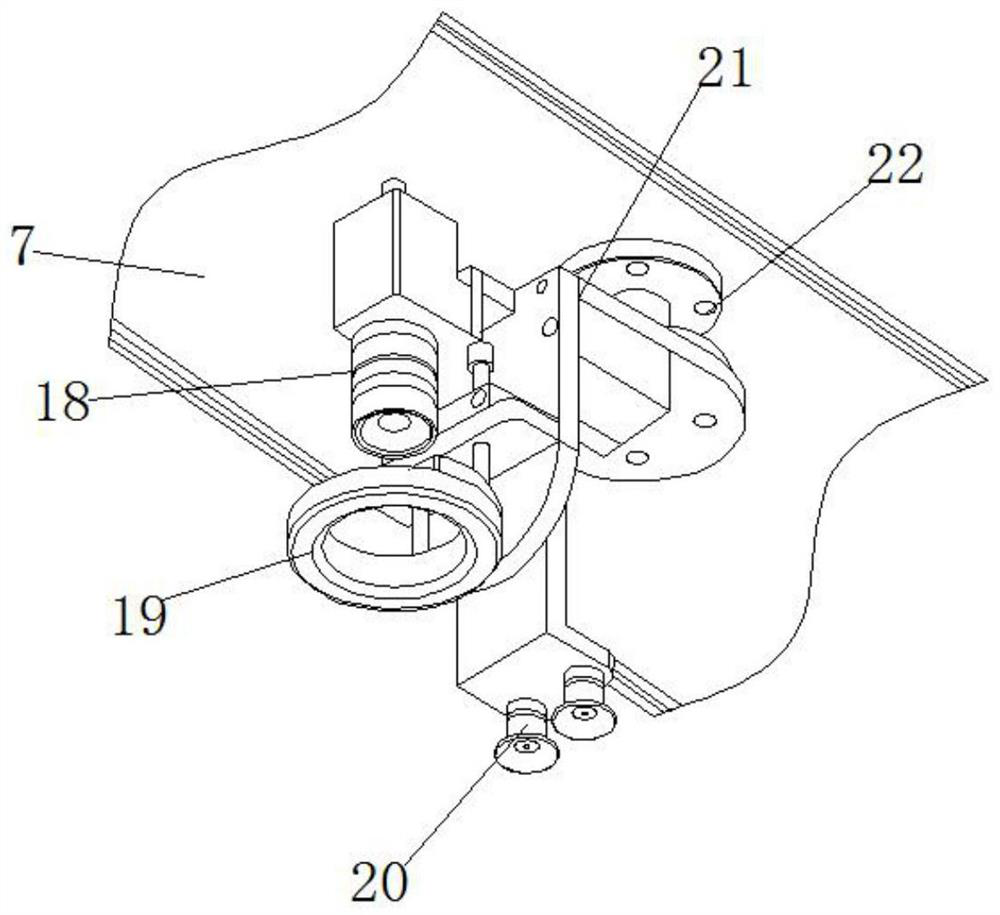

[0030] refer to Figure 1-4 , a kind of automobile coat rack detection frock, comprising a material table 1 and a search cover 7, the top outer wall of the material table 1 is provided with a workbench 11, and the middle part of the workbench 11 is provided with a groove, and the inner wall of the groove is fixed with a bolt The conveying mechanism, the conveying mechanism comprises a conveying bracket 10, a conveying roller 9, a transmission roller and an overlapping conveyor belt 8, and the inner walls of both sides of the conveying bracket 10 are provided with annular belt grooves, and the conveying roller 9 passes between the overlapping conveyor belt 8 and the transmission roller. The transmission fit is formed between them, and the overlapping conveyor belt 8 is slidably connected on the inner wall of the annular belt groove, the middle part of the inner wall of the conveying bracket 10 is provided with a bracket, and the top outer wall of the bracket is fixed with a stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com