Gas storage injection-production string screwed joint sealing failure risk determination system and method

An injection-production pipe string and threaded joint technology is applied in the field of a gas storage injection-production pipe string threaded joint seal failure risk determination system, and can solve the problems of difficulty in evaluating the failure risk of a production pipe string thread seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

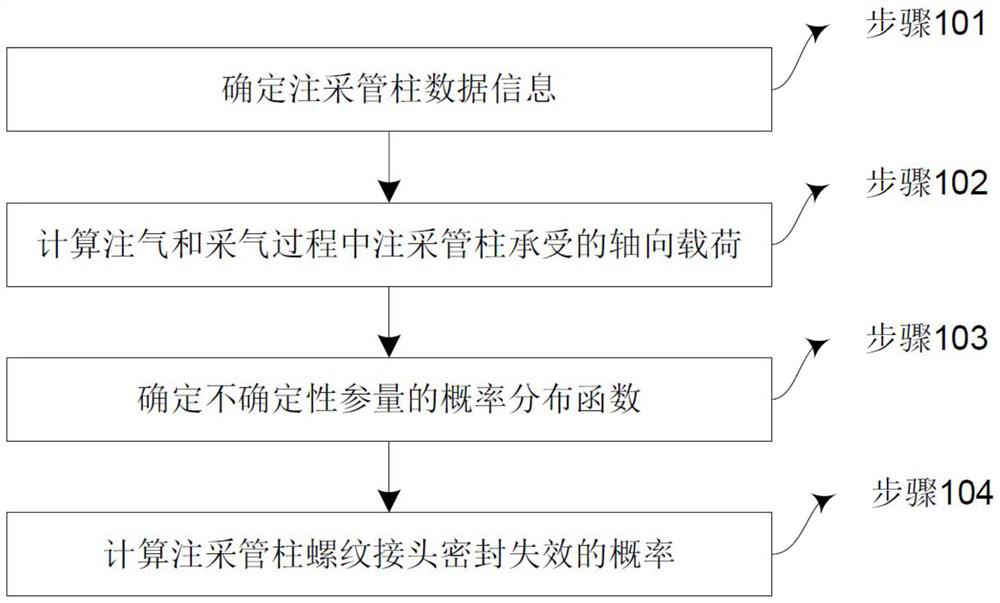

[0086] The injection-production string threaded joint seal failure risk measurement system provided in this embodiment includes an injection-production string information module, an injection-production string load calculation module, a parameter probability distribution function determination module, and an injection-production string thread joint seal failure risk calculation module .

[0087] Wherein, the injection-production string information module: used to determine the basic data information of the injection-production string;

[0088] The injection-production string load calculation module: used to calculate the axial load borne by the injection-production string during gas injection and gas production according to the basic data information of the injection-production string;

[0089] The parameter probability distribution function determination module: used to determine the probability distribution function of the uncertainty parameter including the axial load;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com