Slurry valve

A slurry and valve stem technology, applied in the field of slurry valve, can solve the problems of non-continuous grinding, low grinding efficiency, and no continuous force on the valve disc, and achieve the effect of reducing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

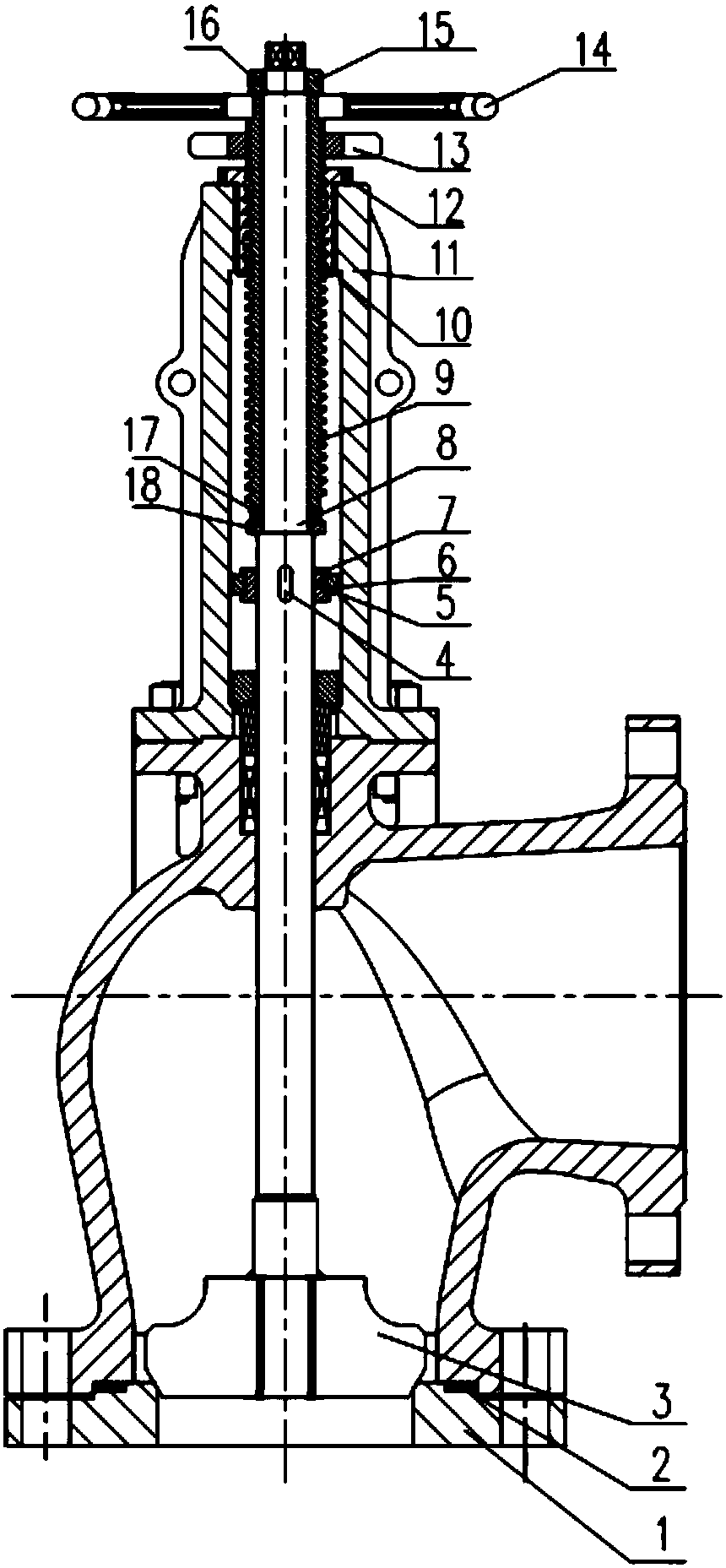

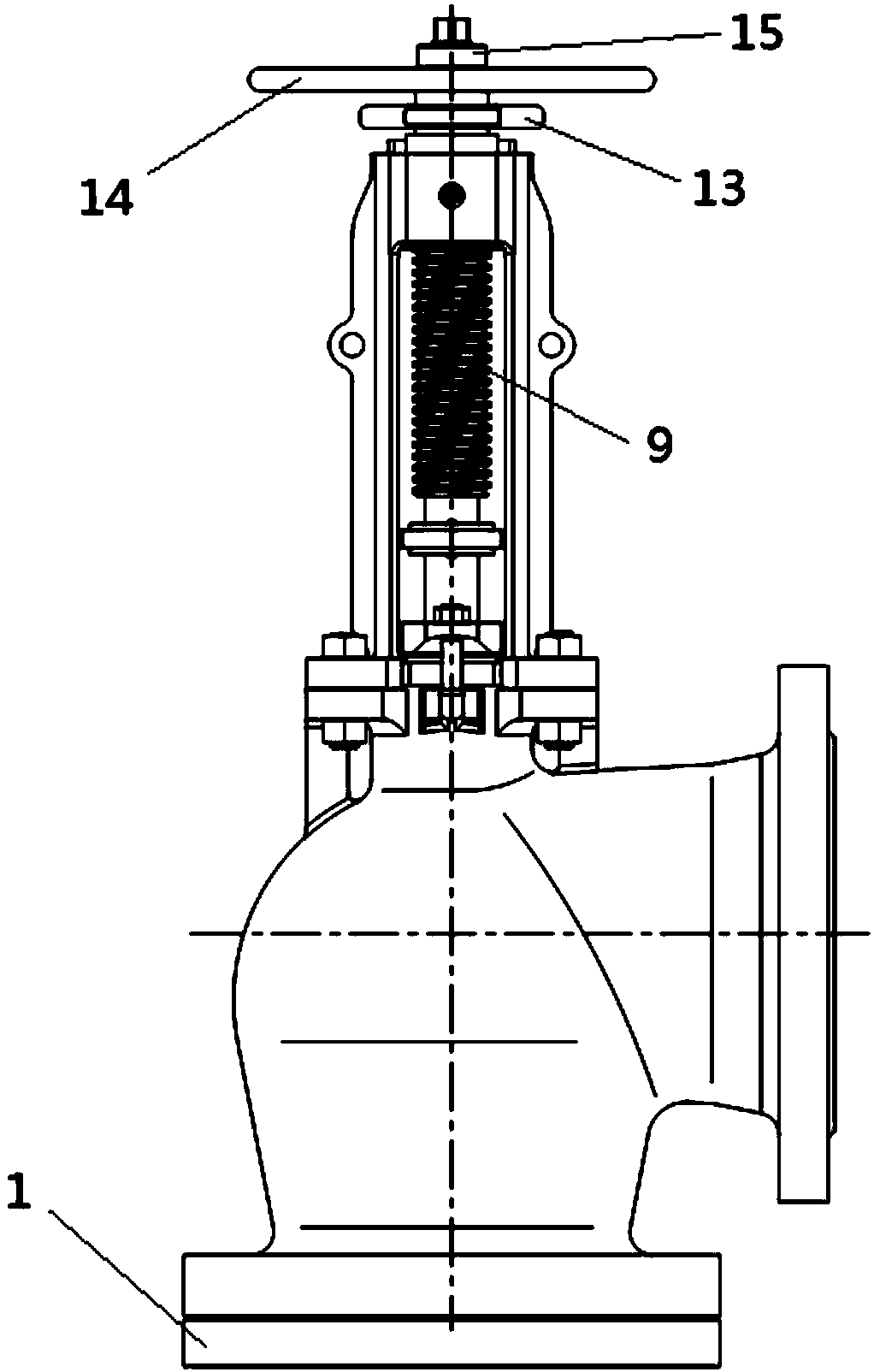

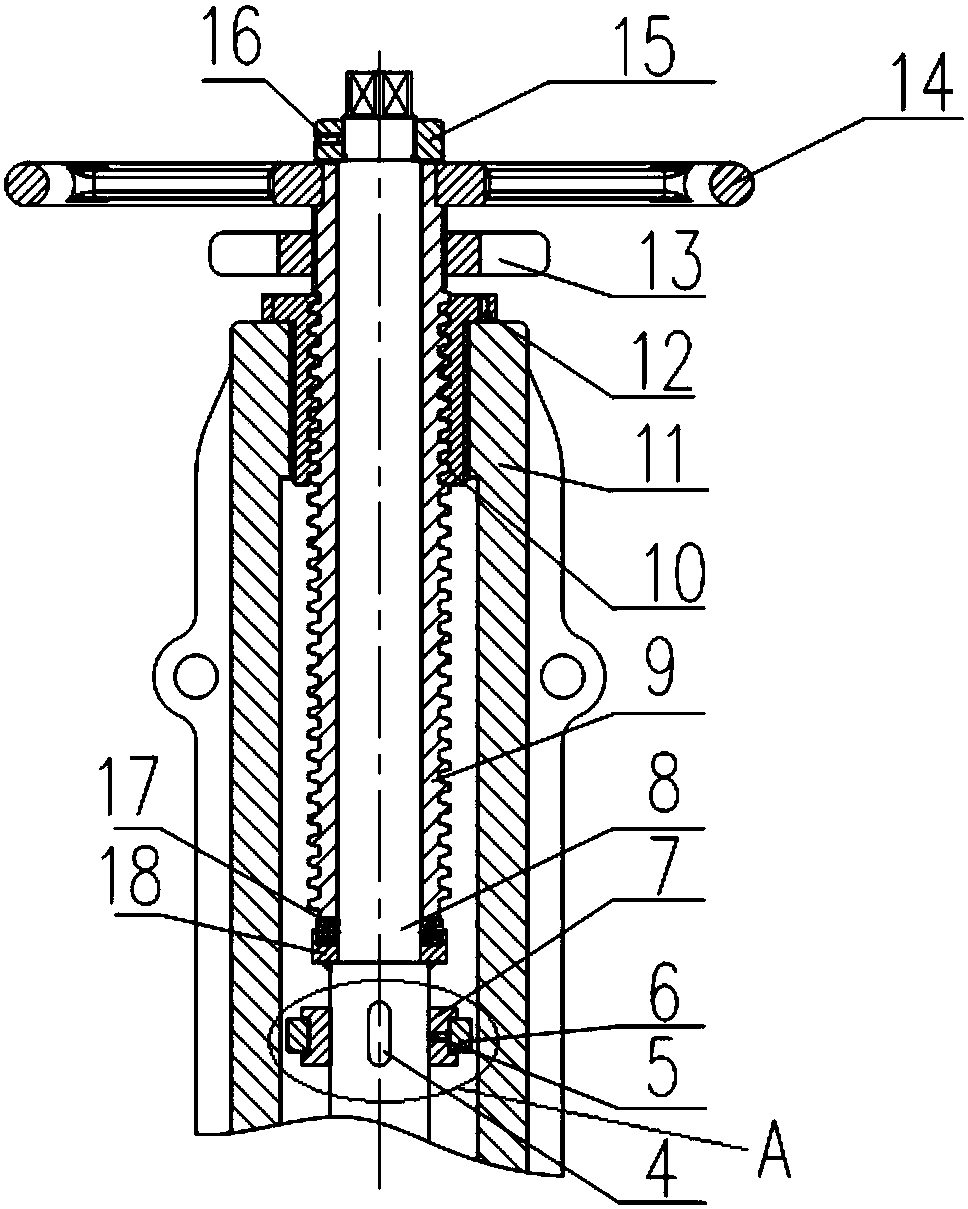

[0042] like Figure 1-7 As shown, it is a specific embodiment of a slurry valve involved in the present invention. The slurry valve includes: a valve seat 1, a valve body, a bracket 11, a valve stem 8, a valve disc 3, a valve stem nut 9, a first An anti-rotation structure, a second anti-rotation structure, two coupling structures and a second driving structure 14 .

[0043] In this embodiment, the valve seat 1 is fixed at the lower end of the valve body, the bracket 11 is fixed at the upper end of the valve body, a cavity is formed inside the valve body, and the side of the valve body A cavity inlet is formed, a cavity outlet is formed at the bottom of the valve body, the valve seat 1 is arranged at the cavity outlet, and the valve seat adopts a structure separated from the valve body, which is convenient for the valve seat repairs.

[0044] A winding pad 2 is provided at the joint between the valve seat 1 and the valve body, and the design of the winding pad 2 can improve t...

Embodiment 2

[0063] like Figure 8 As shown, different from Embodiment 1, the combined structure of the second anti-rotation structure and the second driving structure can also be replaced by a gear box 19, and at the same time, the structural form of the bracket is changed, and the bracket The upper end of the upper end is a flange surface, and the gear box 19 is connected with the flange surface of the bracket by a fourth screw 20. The gear box 19 includes a gear box nut 21 threaded with the valve stem nut 9 and Gearbox handwheel.

[0064] When the gear box hand wheel is turned, the gear box nut 21 rotates, causing the valve stem nut 9 to move up and down, thereby driving the valve stem to move up and down, so as to realize the opening and closing of the valve.

[0065] When grinding is required, turn the gear box handwheel, first adjust the valve to the closed state, then stop turning the gear box handwheel, so that the gear box nut 21 cannot rotate, and then connect the valve stem 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com