Organic electroluminescent screen body and preparation method thereof

An electroluminescence screen and luminescence technology, which is applied in the field of OLED devices, can solve the problems of reduced aperture ratio, current difference, uneven distribution of electrode wiring resistance inside the screen, etc., and achieve the path of increasing edge erosion and optimizing Encapsulation performance, the effect of improving the stability of the screen body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

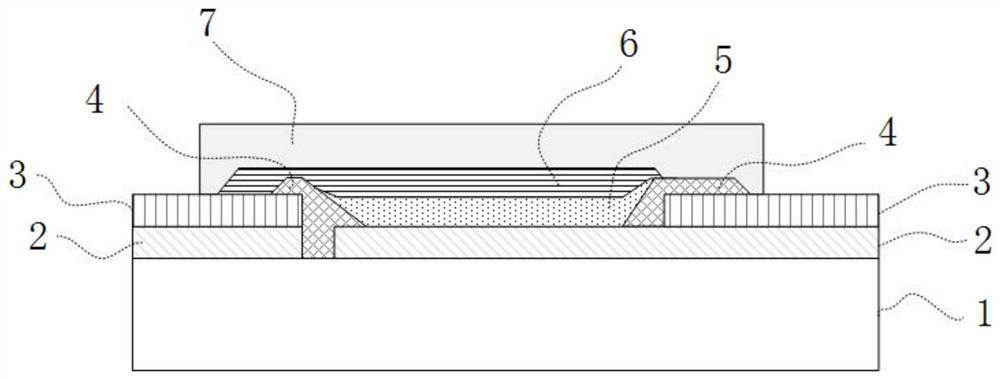

[0055] Such as image 3 As shown, the organic electroluminescent screen provided by the present invention includes: a screen substrate 1, an anode 2, an auxiliary electrode 3, an insulating layer 4, an organic functional layer 5, a cathode 6, an encapsulation layer 7, and the like.

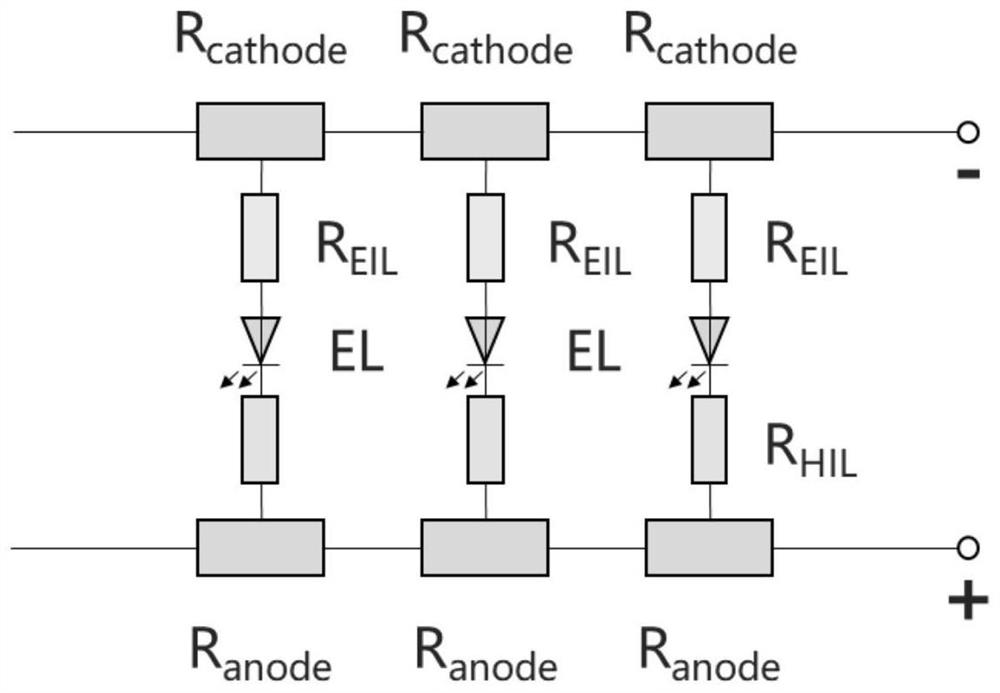

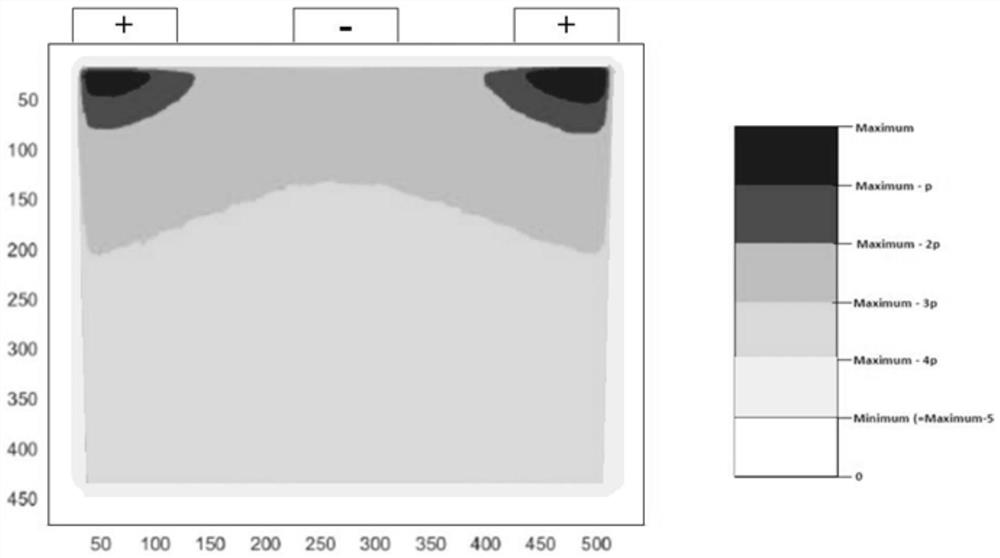

[0056] Such as Figure 4 As shown, when only #1 electrode injects current, the equivalent organic light-emitting diode close to the electrode will obtain higher current. As the resistance value increases or the resistance value distribution is uneven, the luminous brightness of the area far away from #1 will be different. decline. For this reason, the present invention can increase the uniformity of the remote equivalent light emitting diode by introducing a new electrode #2.

[0057] Such as Figure 5 to Figure 11 As shown, the present invention provides an organic electroluminescent screen body. One or more injection electrodes are bound around the OLED screen body. The corresponding electro...

Embodiment 2

[0060] Such as Figure 5 Shown is the organic electroluminescent screen body provided by the present invention with injection electrodes bound on the same edge. Along the edge position of the light-emitting area 13 of the OLED screen body, i anode electrodes 9 and one cathode electrode 8 are provided. The screen body The four edge positions of the light-emitting area are distributed with anode partial inflow areas, which is more convenient for brightness adjustment of the screen light-emitting area; of course, the anode partial inflow areas can also be distributed in two or three of the edge positions of the screen light-emitting area . Wherein the lead wire 11 of the light-emitting area of the anode local inflow region can be a lead wire 11 of the light-emitting area of different shapes or a whole anode or an anode and an auxiliary electrode, such as Figure 6 As shown, lead wires of different shapes can change the resistance value of a single lead wire, thereby changing...

Embodiment 3

[0062] Such as Figure 7 As shown, i anode electrodes 9 are arranged at the four edge positions of the light-emitting area 13 of the square OLED panel, and the method of directly binding the anode electrodes on the sides of the screen is adopted, and a cathode electrode 8 is shared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com