Electric bicycle hub motor with gear protection mechanism

A technology for electric bicycles and protection mechanisms, which is applied to synchronous motors with stationary armatures and rotating magnets, gear transmissions, electromechanical devices, etc., and can solve the problems of manual coil winding, short mileage, broken teeth of planetary gears, etc. problem, to achieve the effect of solving the problem of gear broken teeth, improving the torque bearing capacity, and increasing the mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

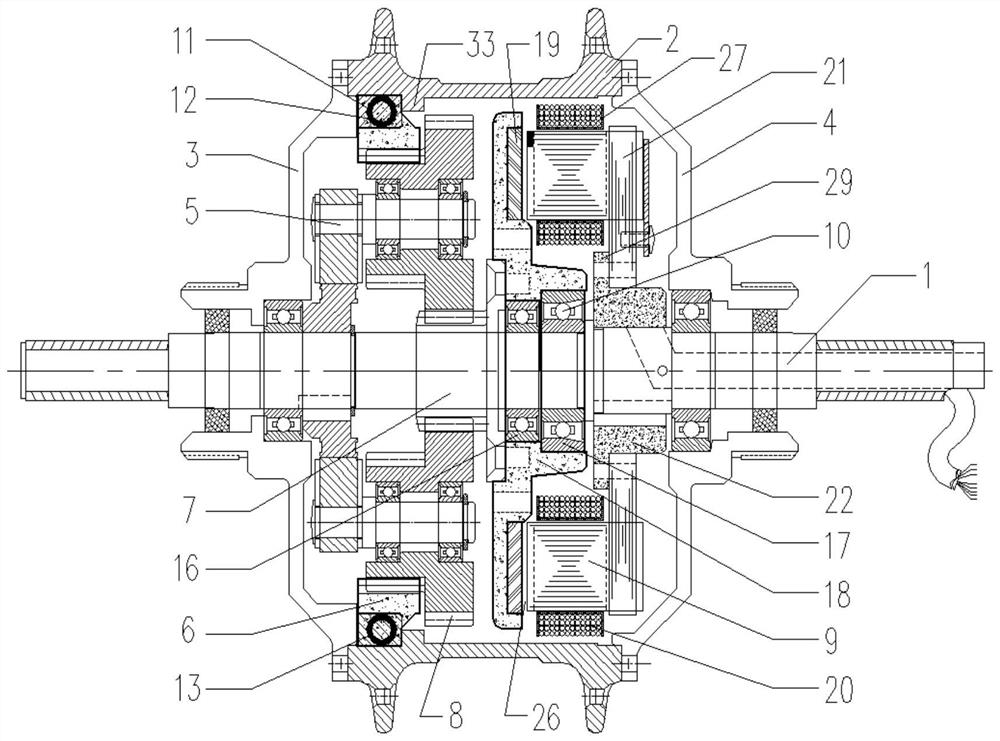

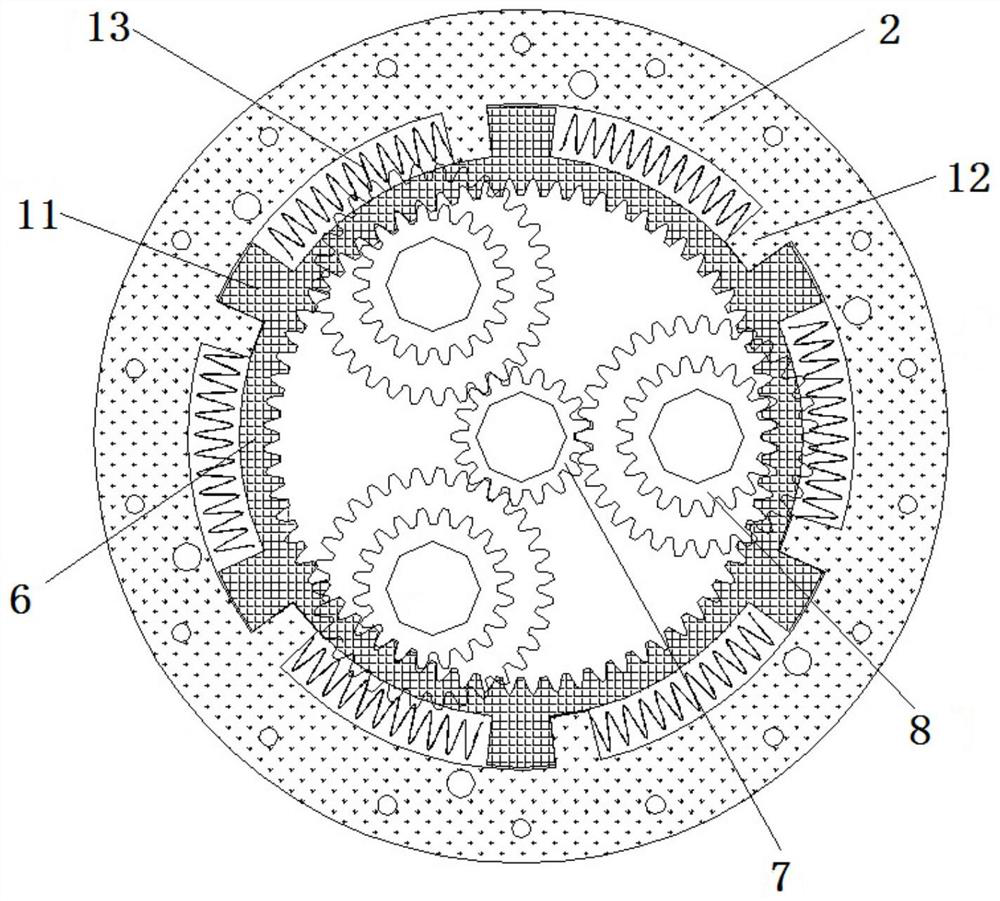

[0041] The stator core 9 with two first mortise grooves 23 of "U" shape is connected with the stator tray 22 sleeved with the stator yoke plate 21 in a mortise and tenon structure:

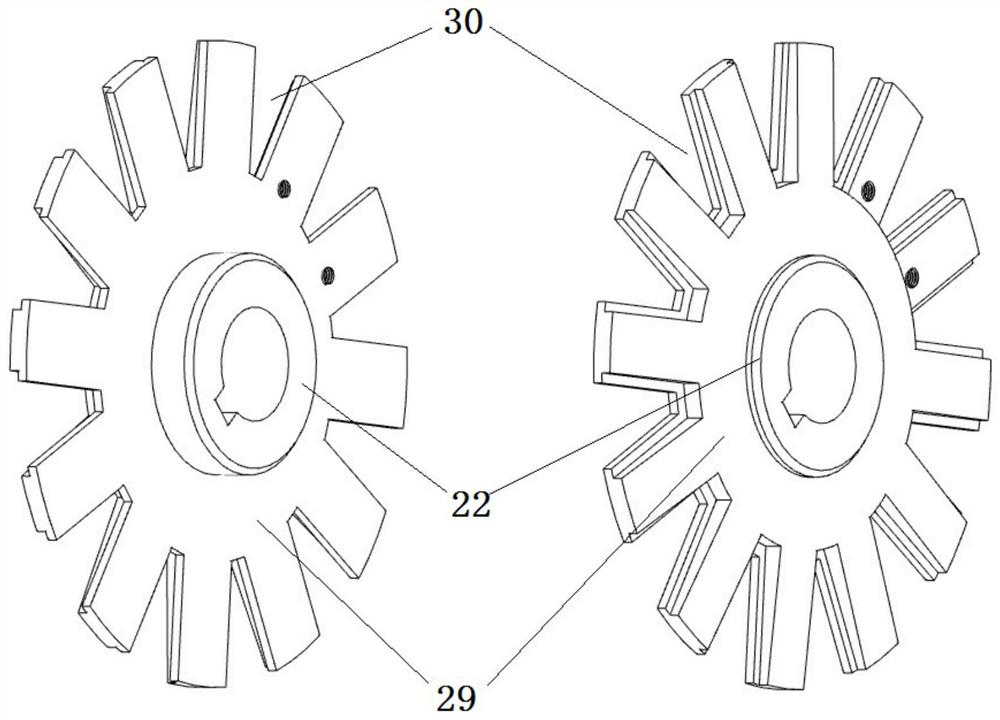

[0042] Such as image 3 , Figure 4 As shown, the first mortise 23 is a "U"-shaped groove, and the stator yoke disk 21 formed by stacking a plurality of silicon steel rings along the axial direction is provided with a circumferential array arrangement connected to the stator core 9. The matched second mortise 28, the end of the stator tray 22 away from the rotor disk 18 has a radial tray 29, and the radial tray 29 is provided with a third mortise 30 connected to the stator core 9 and corresponding to the second mortise 28, The groove shapes of the second mortise 28 and the third mortise 30 correspond to the solid part between the two first mortises 23, and the groove width of the first mortise 23 is consistent with the axial direction of the stator yoke plate 21 and the stator tray 22. The sum o...

Embodiment 2

[0045] The stator core 9 with two first mortise grooves 23 which are "U"-shaped grooves is connected with the stator yoke plate 21 in a mortise and tenon structure:

[0046] The first mortise 23 is a "U"-shaped groove, and the stator yoke plate 21 is provided with a second mortise 28 arranged in a circumferential array to connect and cooperate with the stator core 9. The second mortise 28 is an open groove, and the stator yoke plate 21 The side near the main shaft 1 is also provided with several first connection holes 31 fixedly connected with the stator tray 22; the stator tray 22 has a radial tray 29 at one end close to the rotor disk 18, and the radial tray 29 is provided with the first connection holes. 31 corresponds to the second connecting hole 32, the stator yoke plate 21 is sleeved on the stator tray 22, through the first connecting hole 31 and the second connecting hole 32, fixedly connected by riveting or bolting process; the second connecting hole of the stator yoke...

Embodiment 3

[0049] The stator core 9 whose first mortise 23 is a "U"-shaped groove is connected with the stator yoke 21 with a reinforcing disk 25 in a mortise and tenon structure:

[0050] Such as Figure 5 As shown, the first mortise 23 is a "U"-shaped groove, and the stator yoke disk 21 is formed by stacking a plurality of ring pieces of silicon steel material and reinforcing disk pieces 25 of non-silicon steel material along the axial direction, as shown in Figure 5 As shown, the reinforcing ring piece 25 is stacked on the side of the stator yoke disk 21 away from the rotor disk 18 to enhance the ability of the stator yoke disk 21 to overcome the axial magnetic pull and electromagnetic torque. The stator yoke disk 21 is provided with a circumferential The second mortise 28 arranged in an array to connect and cooperate with the stator core 9, the second mortise 28 is an open groove, and the side near the main shaft 1 of the stator yoke plate 21 is also provided with several first mort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com