High-efficiency platform combination motor

A combined motor and high-efficiency technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low motor efficiency, loss of system power, and complex power coupling, so as to broaden the efficiency platform, reduce system cost, and system cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

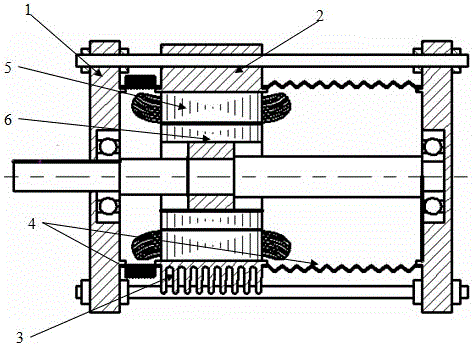

[0029] Such as Figure 1-2 As shown, the high-efficiency platform combined motor described in the embodiment of the present invention is composed of a frame-shaped casing 1, at least one stator I5 and a rotor I6. The stator I5 is equipped with a stator radiator 3, and the frame-shaped casing 1 A rubber bellows 4 is provided between the rotor I6 for waterproofing; the frame-shaped housing 1 is provided with a sliding adjustment device 2 that can slide in the axial direction, and the motor stator is controlled by a stepping motor, a linear motor, a pneumatic device, etc. The sliding control mechanism of I5 or rotor I6 is used to adjust the distance of stator I5 (or rotor I6); one-way bearings relative to the shaft are installed on one rotor I6 or all rotors I6, and several relays are connected outside the motor (the specific number According to demand), the external circuit is connected with a controller and a speed sensor.

[0030] In the high-efficiency platform combined moto...

Embodiment 2

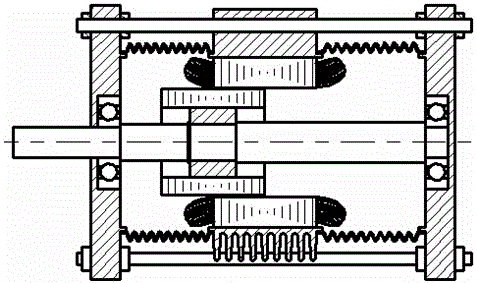

[0032] Such as Figure 3-4 As shown, the high-efficiency platform combined motor described in the embodiment of the present invention is composed of a frame-shaped casing 1, two stators and a rotor, and the two stators are respectively stator I5 and stator II9, and stator II9 is added to stator I5 Externally, the two stators are equipped with a stator radiator 3, and a rubber bellows 4 is provided between the frame-shaped casing 1 and the rotor I6 for waterproofing; the frame-shaped casing 1 is provided with a slide that can slide axially. Adjusting device 2 to adjust the distance of the stator (or rotor);

[0033] In the high-efficiency platform combination motor described in the above embodiments of the present invention, when the motor is combined with a rotor and two stators, a single-pole double-throw relay is externally connected, and the two stators correspond to two different speeds and powers respectively. The combination works as follows:

[0034] Adjust the slid...

Embodiment 3

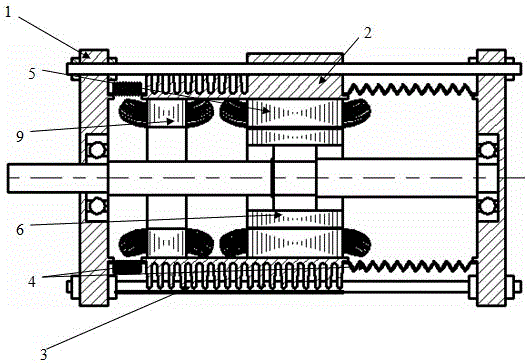

[0036] Such as Figure 5-6 As shown, the high-efficiency platform combined motor described in the embodiment of the present invention is composed of a frame-shaped casing 1, two stators and two rotors, wherein the two stators are respectively stator I5 and stator II9, and stator II9 is added to the stator Outside I5, the stator I5 and the stator II9 are respectively connected to the rotor I6 and the rotor II10 in turn; the two stators are equipped with a stator radiator 3, and a rubber bellows 4 is provided between the frame-shaped casing 1 and the rotor I6 for waterproofing; the said A frame-shaped casing 1 is provided with a sliding adjustment device 2 that can slide in the axial direction to adjust the distance of the stator (or rotor); a one-way bearing 8 relative to the motor shaft 7 is installed on one of the rotors or two rotors ;

[0037] For the high-efficiency platform combination motor described in the above embodiments of the present invention, when the motor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com