Chemical fiber traceless 3D false eyelashes

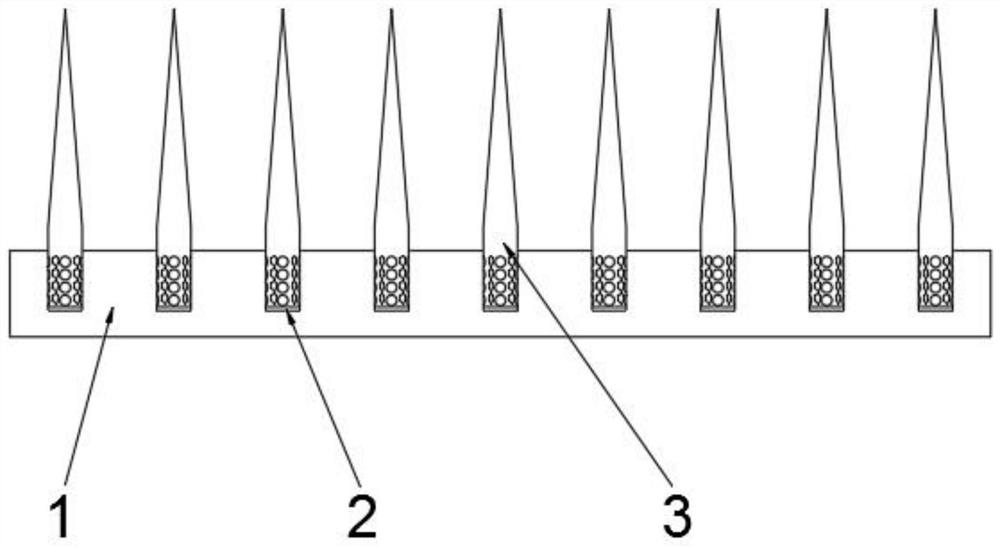

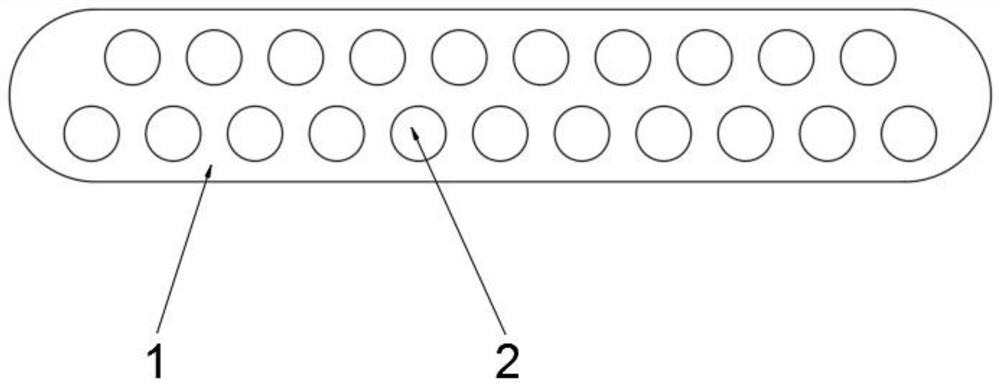

A technology of false eyelashes and chemical fiber, applied in the field of false eyelashes, can solve the problems of heavy marks when wearing false eyelashes, affecting the aesthetics, affecting the three-dimensional feeling of the false eyelashes, etc., and achieves the effects of improving the aesthetics, improving the layering and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The manufacturing process of the eyelash body 3 comprises the following steps:

[0023] Step 1: Take a 50mm heating tube and heat it to 150 degrees Celsius;

[0024] Step 2: Use the heated heating tube to press the chemical fiber eyelashes and heat for 20-30 minutes. After the chemical fiber eyelashes are heated, they will bend under the action of torsion to form a 3D stereoscopic effect;

[0025] Step 3: Pack the false eyelashes into a specially designed package to avoid deformation of the false eyelashes under pressure.

Embodiment 2

[0027] The manufacturing process of the eyelash body 3 comprises the following steps:

[0028] Step 1: Take a 75mm heating tube and heat it to 150 degrees Celsius;

[0029] Step 2: Use the heated heating tube to press the chemical fiber eyelashes and heat for 20-30 minutes. After the chemical fiber eyelashes are heated, they will bend under the action of torsion to form a 3D stereoscopic effect;

[0030] Step 3: Pack the false eyelashes into a specially designed package to avoid deformation of the false eyelashes under pressure.

Embodiment 3

[0032] The manufacturing process of the eyelash body 3 comprises the following steps:

[0033] Step 1: Take a 100mm heating tube and heat it to 150 degrees Celsius;

[0034] Step 2: Use the heated heating tube to press the chemical fiber eyelashes and heat for 20-30 minutes. After the chemical fiber eyelashes are heated, they will bend under the action of torsion to form a 3D stereoscopic effect;

[0035] Step 3: Pack the false eyelashes into a specially designed package to avoid deformation of the false eyelashes under pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com