Feed crushing and stirring device for dairy farming

A technology for mixing equipment and feed, which is applied to feed, mixers with rotary mixing devices, mixers, etc., and can solve the problems of high labor intensity, manual shaking, insufficient pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

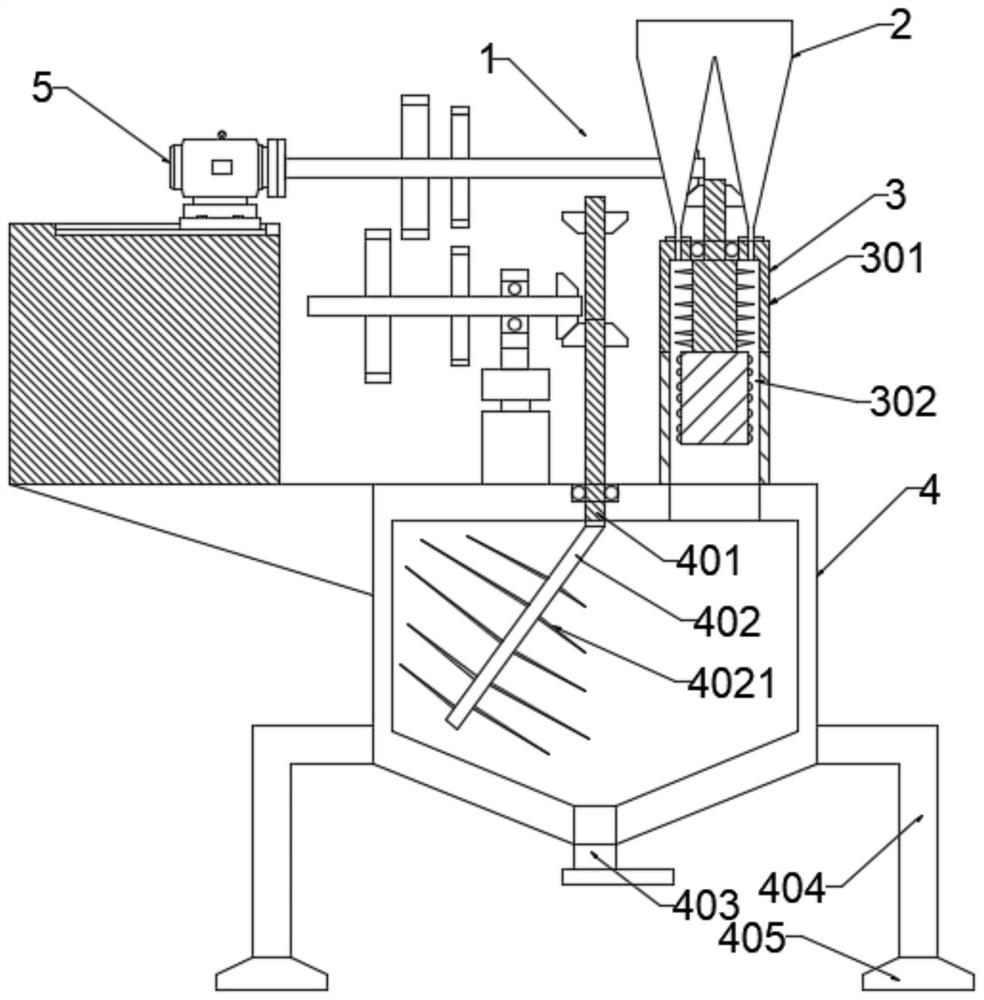

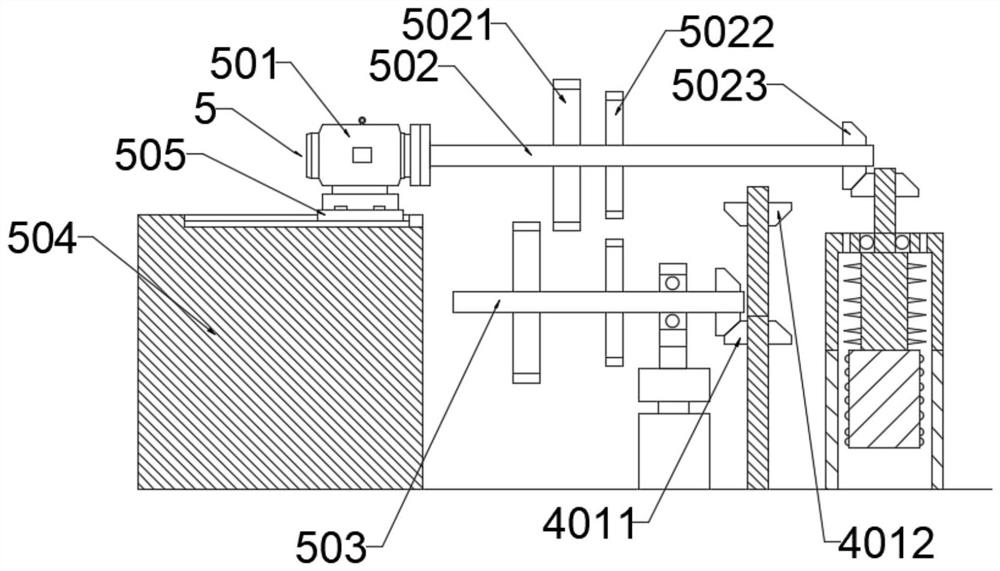

[0026] See Figure 1-5 , A milk cow breeding feed crushing and stirring equipment, including an equipment body 1, the equipment body 1 including a hopper 2, a crushing mechanism 3, a stirring chamber 4, and a driving mechanism 5. The crushing mechanism 3 includes a crushing chamber 301 and a crushing and grinding mechanism. A rod 302, one end of the grinding and grinding rod 302 is provided with a first driven shaft 3021, and the first driven shaft 3021 is fixedly connected with a first bevel gear 3024; the driving mechanism 5 includes a motor 501, a first driving shaft 502, and a motor The motor shaft of 501 is fixedly connected to the first drive shaft 502. One end of the first drive shaft 502 is provided with a fourth bevel gear 5024, and the fourth bevel gear 5024 is meshed and connected with the first bevel gear 3024; the first driven shaft 3021 penetrates After passing through the pulverizing chamber 301 and rotatingly connected to its top through a bearing, the pulverizi...

Embodiment 2

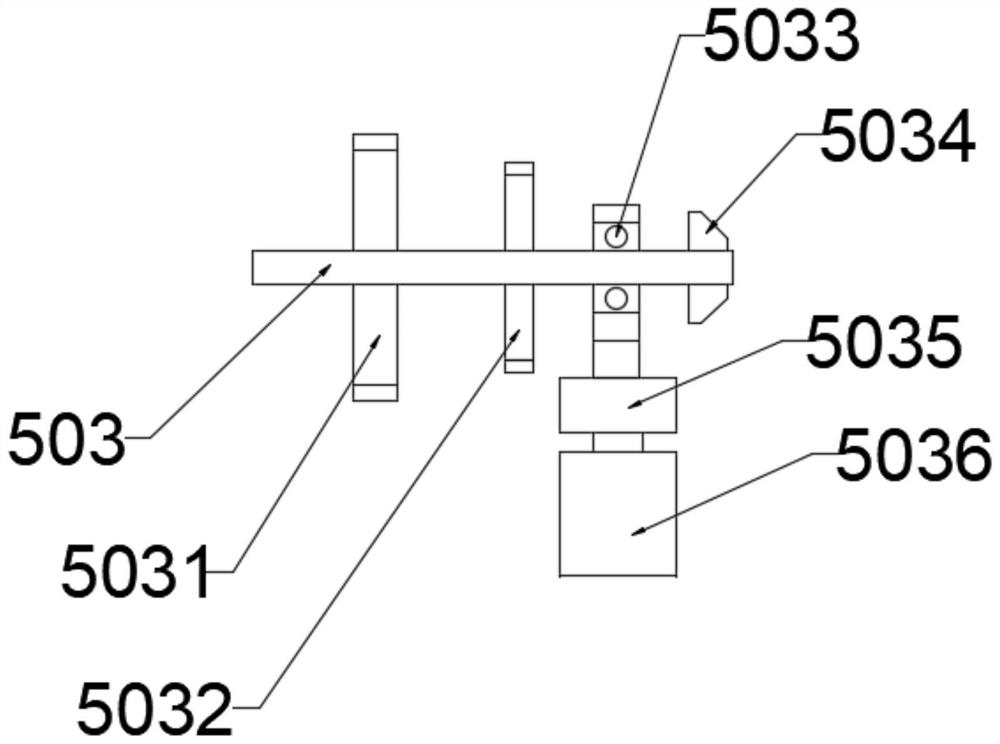

[0031] This embodiment is based on the embodiment 1, and further, the first drive shaft 502 is provided with a first spur gear A5021 and a first spur gear B5022; the drive mechanism 5 includes a second drive shaft 503, a drive shaft 503 A second spur gear A5031, a second spur gear B5032 and a fifth bevel gear 5034 that cooperate with the first spur gear B5022 are provided on the first spur gear A5021; a seated bearing is provided on the second drive shaft 503 5033, the seated bearing 5033 is fixedly connected with a connecting block 5035, the connecting block 5035 is fixedly connected with a cylinder 5036, and the cylinder 5036 is fixedly connected to the top of the mixing chamber 4; the second driven shaft 401 is provided with a fifth bevel gear 5034 The second bevel gear 4011 and the third bevel gear 4012 are matched.

[0032] The motor 501 is fixedly connected with a mounting base 505, the top of the mixing chamber 4 is fixedly connected with a mounting base 504, the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com