Electric device for removing heavy metal in soil

A heavy metal and soil technology, applied in the restoration of polluted soil and other directions, can solve the problems such as the difficulty of adjusting the anode strong acid electrode solution in time, the difficulty of removing heavy metal ions to meet the actual needs, and the rainwater interfering with the treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

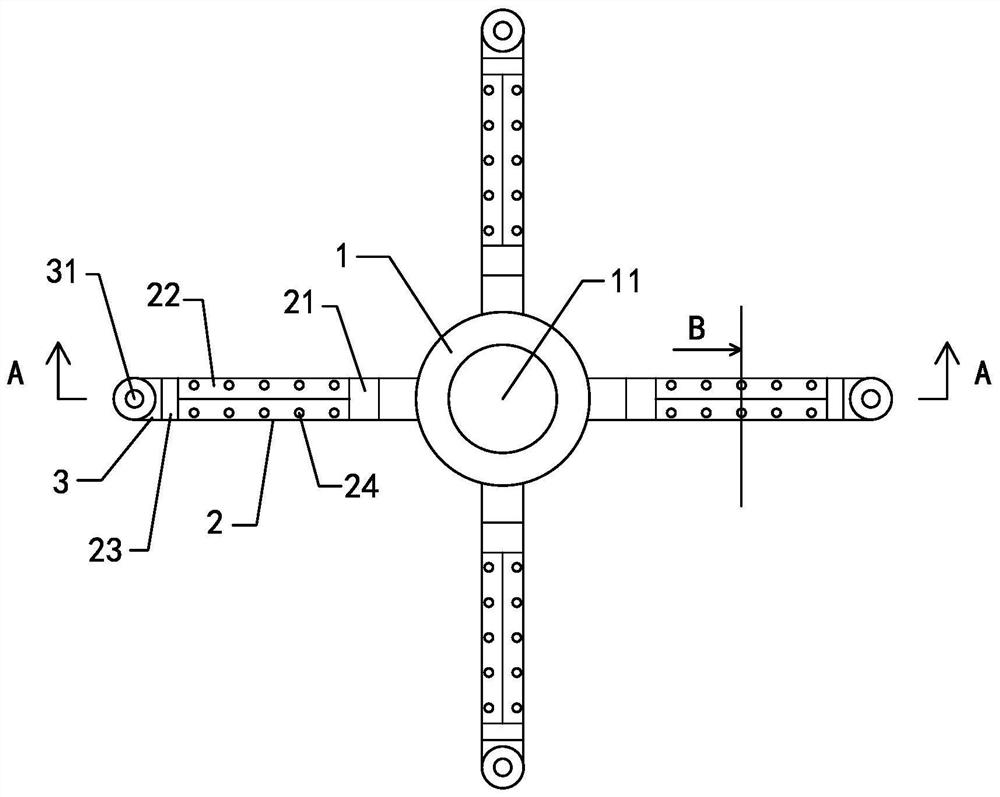

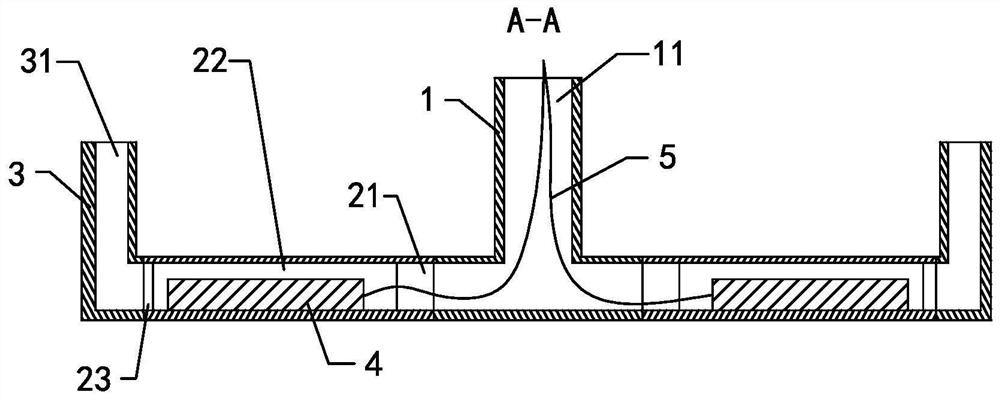

[0028] see Figure 1-3 , what this embodiment provides is a kind of electric soil heavy metal removal device, comprises power supply (not shown in the figure), cathode (not shown in the figure), anode rod 4, water inlet pipe 1, anode placement pipe and water outlet pipe 3.

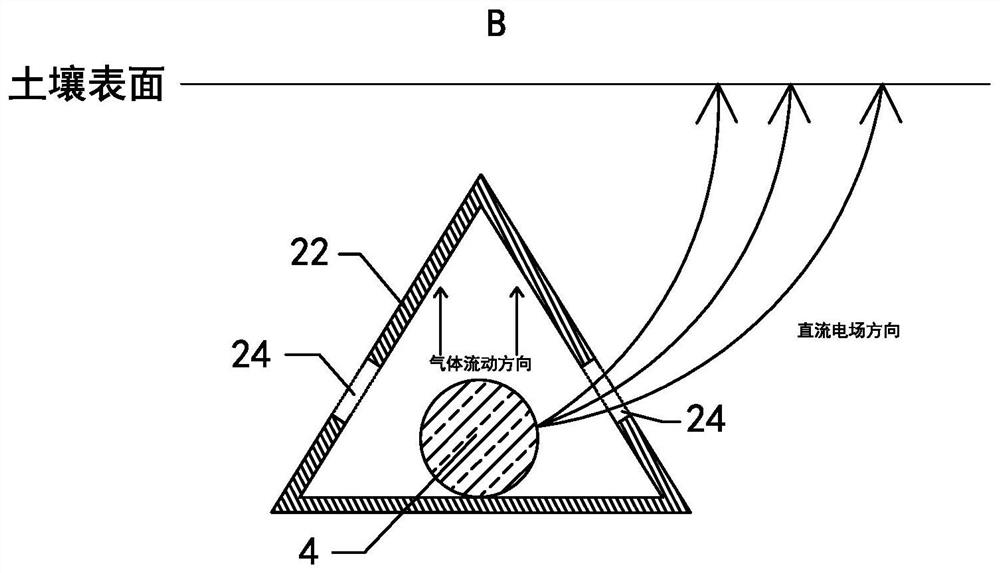

[0029] The power supply is located above the soil, the anode rod 4 is located in the soil, the cathode is arranged on the soil surface, and the power supply, the anode rod 4 and the cathode are electrically connected in turn to form a loop. After the power is turned on, a DC electric field is formed between the anode rod 4 and the cathode, that is, between the anode rod 4 and the soil surface, and the heavy metal ions in the soil continue to migrate to the cathode.

[0030] The water inlet pipe 1, the anode placement pipe and the water outlet pipe 3 are connected in sequence. Water enters the water inlet pipe 1 from the water inlet 11 of the water inlet pipe 1, then flows through the anode placement pipe, ...

Embodiment 2

[0045] see Figure 4 The difference between this embodiment and Embodiment 1 is that the anode placement tube also includes a triangular prism 25 located below the placement section 22 , one side wall of the triangular prism 25 is fixed to the bottom outer wall of the placement section 22 . The bottom side edge of the triangular prism 25 can make the placement section 22 more easily pressed into the soil, and the solid triangular prism 25 after being pressed can make the center of gravity of the anode placement tube move down, so that the anode placement tube can be placed in the soil more easily. for stability. In this embodiment, the cross-sectional outline of the anode placement tube at the placement section 22 is quadrilateral, and further, the four vertices of the quadrilateral are located on the same circle, so that the cross section of the anode placement tube at the placement section 22 is closer to Round shape, thereby reducing the design length of the transition pip...

Embodiment 3

[0047] see Figure 5 The difference between this embodiment and Embodiment 1 is that the upper end of the main water inlet is provided with a water collecting funnel 12 that increases the area of the water inlet 11, and the upper end of the outlet pipe 3 is provided with a ring cover 32 that reduces the area of the water outlet 31. When it rains, the water collecting funnel 12 can increase the amount of rainwater collected at the water inlet 11. After the area of the water outlet 31 shrinks, the amount of rainwater falling into the water outlet 31 is less than that at the water inlet 11, thereby ensuring the utilization of rainwater. In this case, prevent the liquid anolyte from flowing backward from the water outlet 31 to the water inlet 11.

[0048] In this embodiment, the outer wall of the outlet pipe 3 located above the soil is also provided with an annular buffer cover 37. The middle part of the buffer cover 37 is sunken downward, so that the entire buffer cover 37 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com