Lead-acid storage battery electrode terminal reshaping device

A lead-acid battery, electrode terminal technology, applied in lead-acid battery, lead-acid battery construction, driving device and other directions, can solve the problems of battery cover perforation, waste of manpower and material resources, insufficient precision of manual shaping operation, etc., to achieve low resource cost, The effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

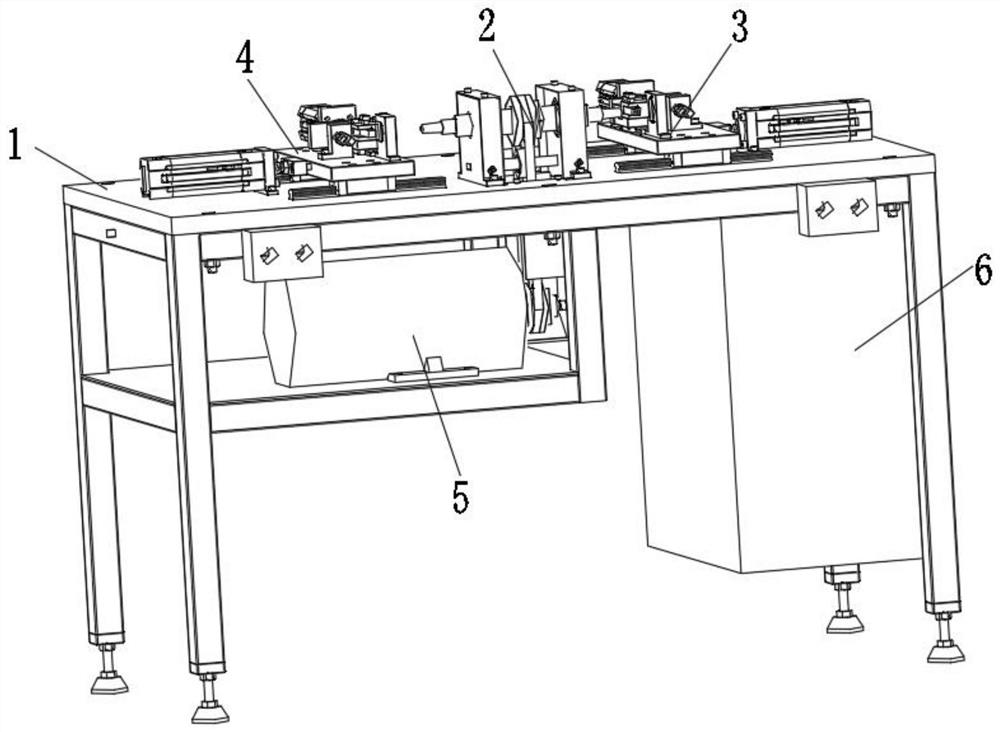

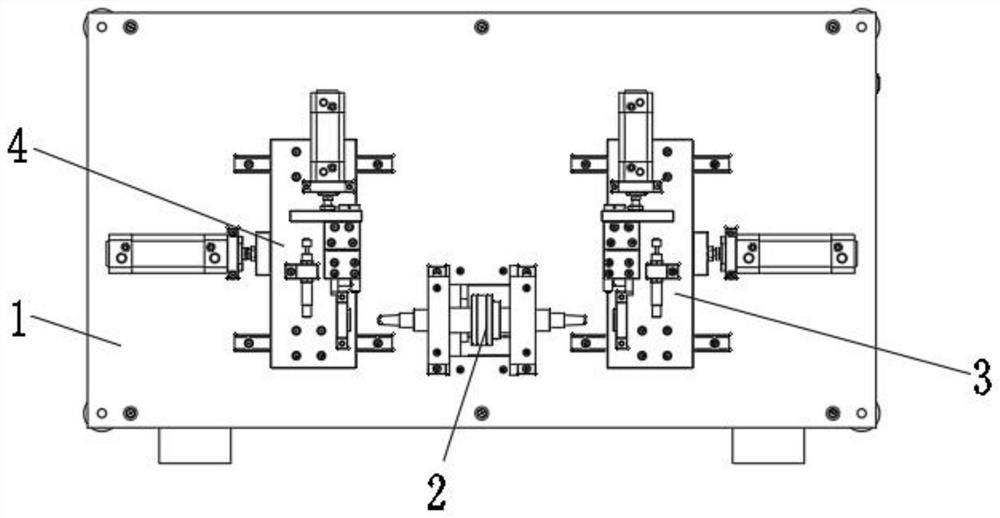

[0028] like figure 1 and figure 2 As shown, a lead-acid battery electrode terminal shaping device includes a workbench 1; a rotating mechanism 2 is installed in the middle of the surface of the workbench 1, and negative terminal trimming mechanisms with the same structure are symmetrically provided on both sides of the turning mechanism 2 3. A positive terminal trimming mechanism 4, a motor 5 is installed on the bottom of the workbench 1, and the motor 5 is connected to the rotating mechanism 2 through a transmission V-belt 51;

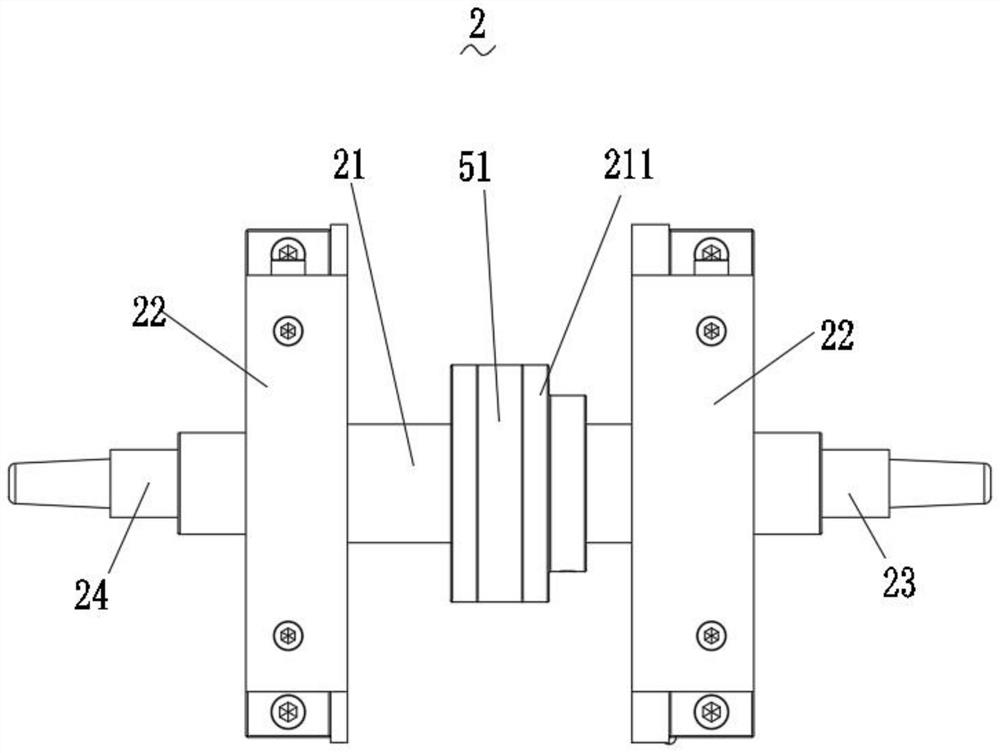

[0029] The two ends of the rotating mechanism 2 are fitted with the negative terminal and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap