Aluminum Alloy Die Casting Automatic Trimming Machine

A die-casting and aluminum alloy technology, which is applied in the field of aluminum alloy die-casting trimming equipment, can solve the problems of personal safety, single operation action, and damage to workpieces, and achieve the effect of saving space and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

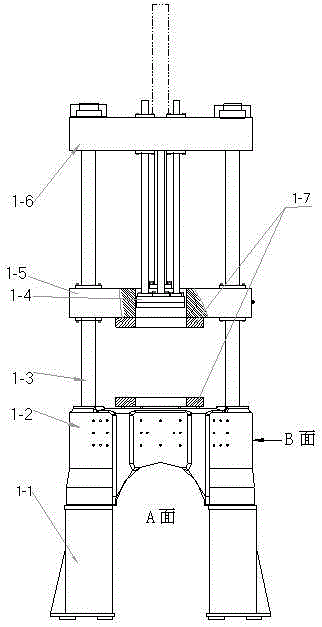

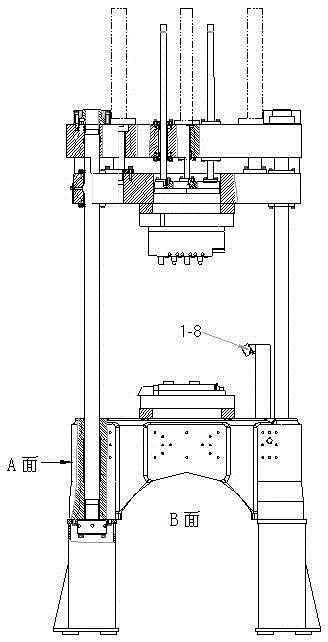

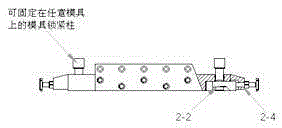

[0023] Aluminum alloy die-casting automatic trimming machine, which includes: machine tool support 1-1, base assembly 1-2, Gelin column 1-3, pressing plate assembly 1-4, moving plate assembly 1-5 and upper Plate assembly 1-6; upper plate assembly 1-6 is equipped with a hydraulic station, and upper plate assembly 1-6 is connected with base assembly 1-2 through the columbine column assembly 1-3; moving plate assembly 1 -5 is set between the upper plate assembly 1-6 and the base assembly 1-2, the moving plate assembly 1-5 is driven by the hydraulic station to move up and down along the Corinthian column assembly 1-3; the upper plate assembly 1-6 is connected with the compression plate assembly 1-4, and the compression plate assembly 1-4 is driven to move up and down by the hydraulic station; it also includes: clamping template assembly 1-7 and error prevention device 1-8 ; The clamping formwork assembly 1-7 is composed of an upper clamping formwork assembly and a lower clamping f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com