A device for cutting long slices of food materials for hotels

A technology for ingredients and hotels, which is applied in the field of long-slicing devices for ingredients used in hotels, can solve problems such as hand-cutting efficiency, and achieve the effects of easy operation, efficient slicing, and simplified operation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

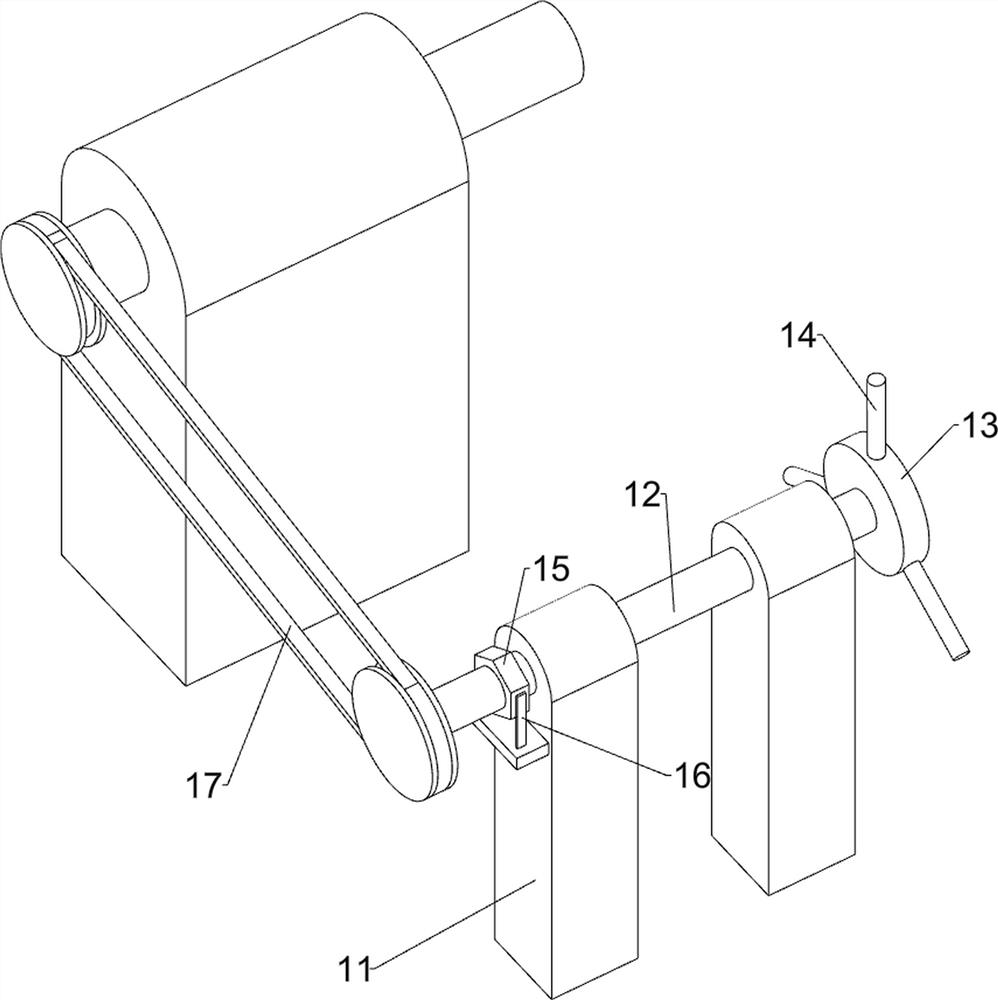

[0025] A device for cutting long slices of food materials for hotels, such as Figure 1-5 As shown, it includes a base 1, a support column 2, a workbench 3, a collection frame 4, a rotary refueling mechanism 5, and a knife feeding mechanism 6. The top of the base 1 near the edge is evenly connected to the support column 2, and the top of the support column 2 A workbench 3 is provided between them, a collection frame 4 is provided on the front side of the top of the base 1, a rotary refueling mechanism 5 is provided on the rear side of the top of the workbench 3, and a knife feeding mechanism 6 is provided on the front side of the top of the workbench 3.

[0026] When people need to cut the ingredients into continuous long pieces, this device can be used. First, people process the ingredients into a cylindrical shape, and then fix the processed ingredients on the rotary refueling mechanism 5, so that the ingredients are in contact with the knife feeding mechanism 6 , and then t...

Embodiment 2

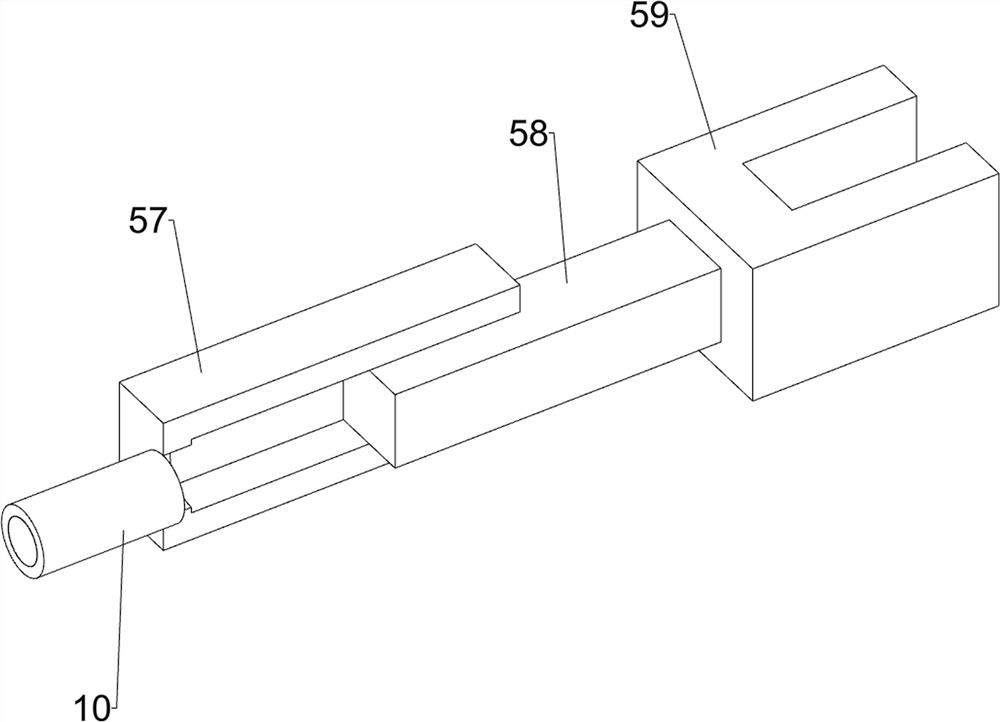

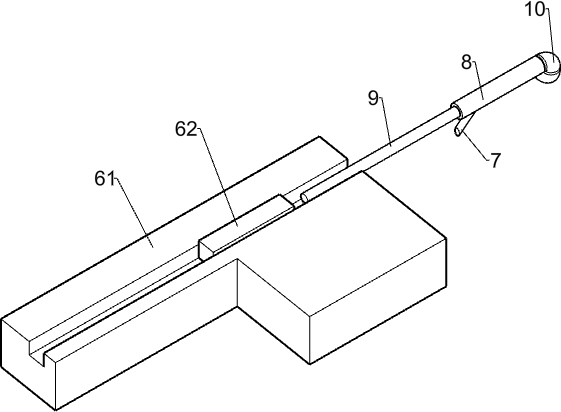

[0032] On the basis of Example 1, such as image 3 and Figure 5-7 As shown, it also includes a fixed post 7, a hydraulic cylinder 8, a piston post 9 and a hydraulic pipe 10. The left rear side of the slide rail seat 61 is provided with a fixed post 7, and the fixed post 7 is fixedly connected with a hydraulic cylinder 8. A piston column 9 is connected in a sliding manner, and the piston column 9 is connected to the slider 62. The rear end of the hydraulic cylinder 8 is provided with a hydraulic pipe 10, which passes through the lower side of the second bearing seat 56, and the end of the hydraulic pipe 10 is connected to the hydraulic box. 57 clearance fit.

[0033] When the material is cut and the knife rest 63 drives the slider 62 to move forward, the slider 62 drives the piston rod 9 to move forward, and the piston rod 9 moves forward through the hydraulic cylinder 8 so that the hydraulic pipe 10 sucks the piston block 58 to move to the left , the clamping block 59 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com