Grouting cover and container for manufacturing standard test piece of loading case steel bar connector

A technology of standard test pieces and connectors, applied in the direction of manufacturing tools, auxiliary molding equipment, supply devices, etc., can solve the problems that the effect cannot be verified, and achieve the effects of grouting, cost saving, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that in this embodiment, the orientation words "top", "bottom", "left" and "right" are all described according to the drawings and do not constitute a limitation to the present invention.

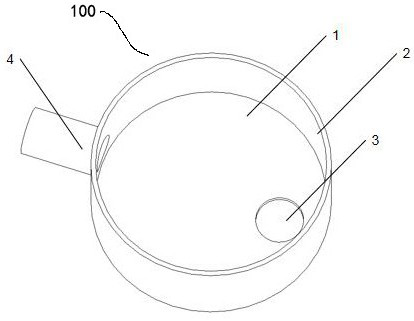

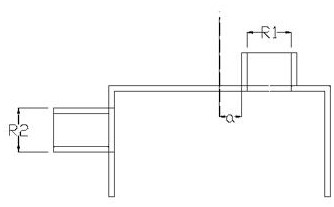

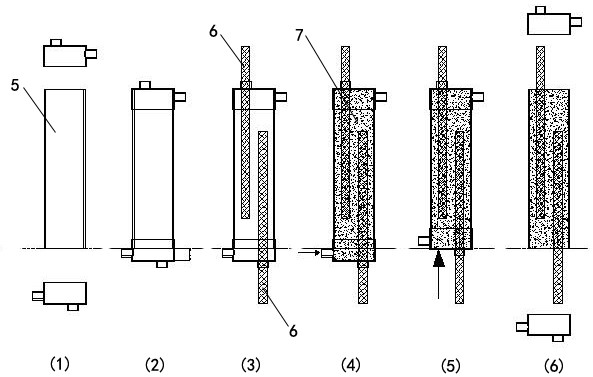

[0024] Attached below Figure 1-3 The present invention is further described in detail: a grouting cover for making a load box steel bar connector standard test piece, such as figure 1 As shown, the grouting cover 100 is composed of a cover base plate 1, a cover enclosure 2, a reinforced pipe 3 and a grout tube 4; the cover base plate 1 and the cover enclosure 2 form a cylinder with an open end and a hollow inside, and the cover base plate 1 is a column The bottom plate of the body, the cover enclosure 2 is the side wall of the cylinder, and a hole is provided on the cover bottom plate 1 to allow the steel bar 6 to penetrate. 3 Corresponding to and connected to the hole position, the steel bar 6 is penetrated by the steel bar pipe 3 and the hole; a through hole is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com