A precise centering device and centering method for installation of pipes in holes

A technology of centering device and inner pipeline, which is applied in the direction of pipeline laying and maintenance, pipe, pipe/pipe joint/pipe fitting, etc., which can solve the problems of difficulty in making and carrying, many models, and insufficient cement pouring, and achieves centering operation. Convenient and flexible, simple and compact structure, easy to process and produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

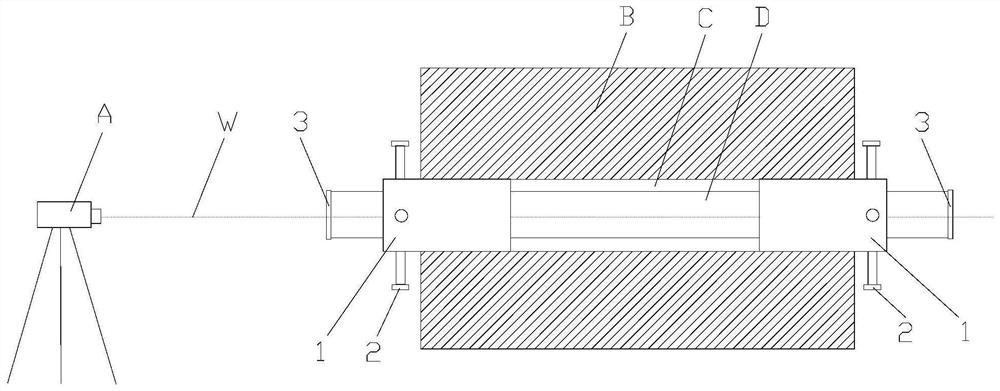

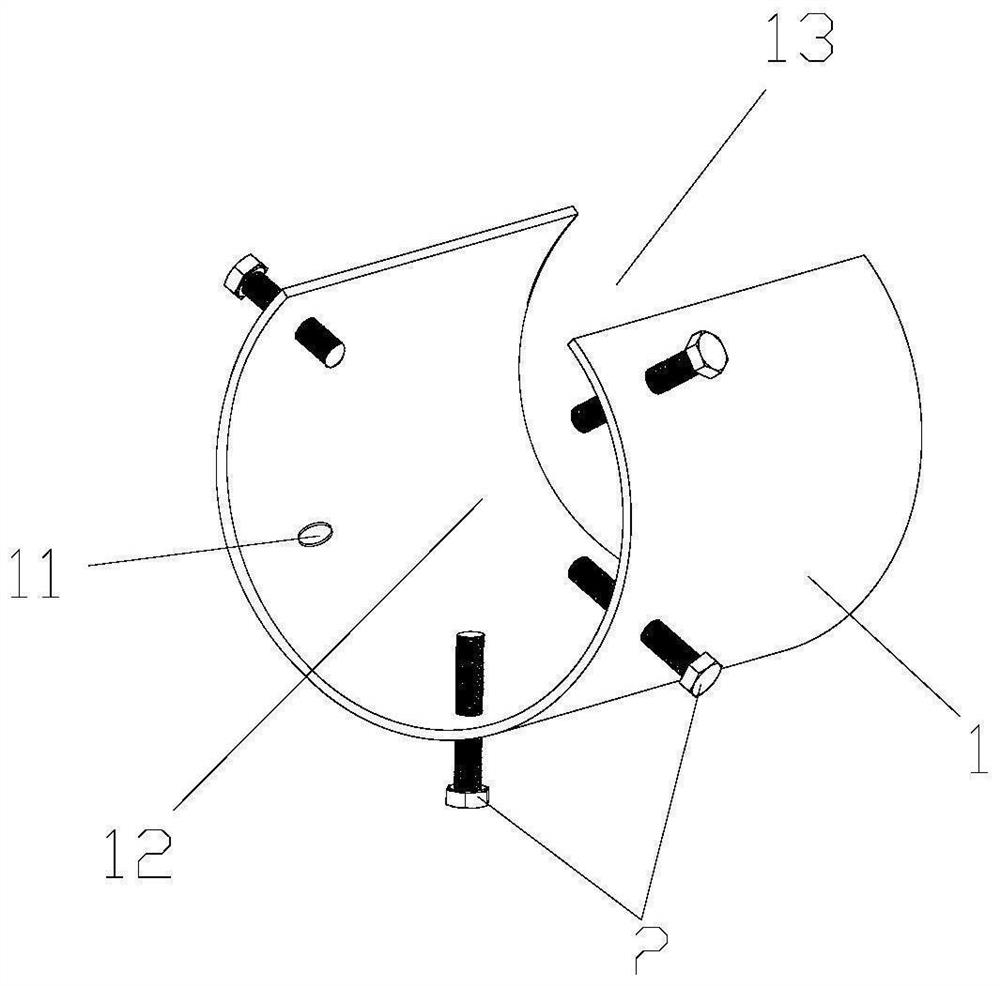

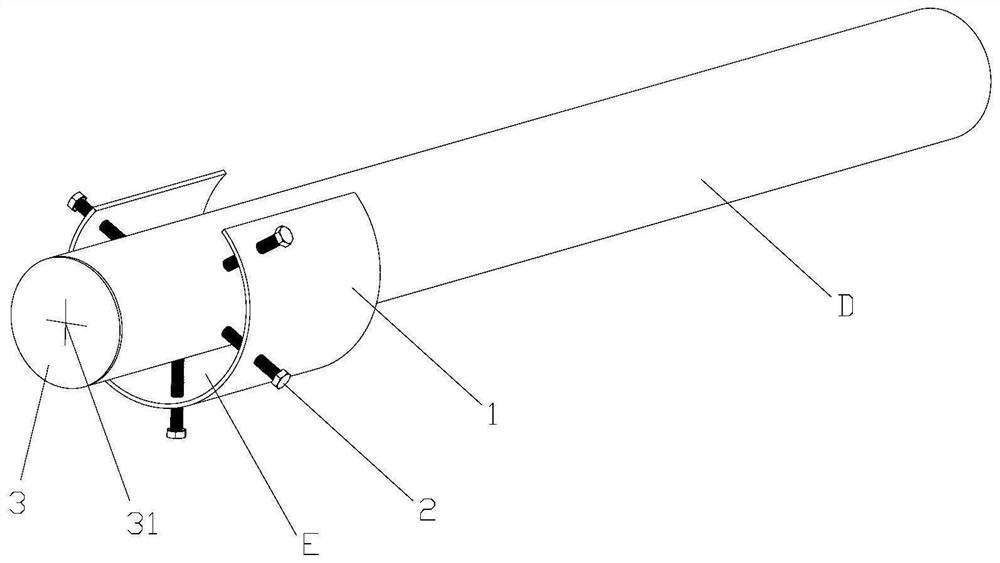

[0041] Embodiment 1: During construction, first insert the heads of the two base tubes 1 into the two ends of the installation holes, that is, on the left and right sides of the wall, and then insert the pipes into the accommodating chambers 12 of the two base tubes 1 . Then two correction plate assemblies 3 are respectively capped on the ports at the left and right ends of the pipeline. Turn on the laser total station to determine the installation axis of the pipeline, and turn on the laser total station to emit laser light. Then, the plurality of adjustment limit rods 2 are rotated to push the pipeline to move in multiple directions in the accommodation cavity 12 to adjust the position of the pipeline. For example, when an adjustment limit rod 2 on the left side of the base pipe 1 is tightened clockwise, the adjustment limit rod 2 on the left side gradually extends into the accommodation cavity 12, and gradually pushes the pipeline in the accommodation cavity 12 to the right...

Embodiment 2

[0042] Embodiment 2: The difference from Embodiment 1 is that under certain construction conditions, pipes may have been inserted into the installation holes in advance, and then centered. At this time, the two base tubes 1 can be sleeved on the tubes from both ends of the tubes, so that the tubes can be inserted into the accommodation chambers 12 of the two base tubes 1 at the same time. Then move the two base tubes 1 and insert the heads of the two base tubes 1 into the two ends of the mounting holes respectively; then perform subsequent position adjustment and centering operations.

[0043] Through the above special scientific design, it has the following technical advantages:

[0044] One is the precise centering device of the present invention, which has a simple and compact structure and is easy to process and manufacture. Through the mutual support and mutual cooperation of the base tube 1, multiple adjustment limit rods 2, and two correction plate assemblies 3, it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com